Despite a lukewarm sustainability agenda here in the United States, global bearing manufacturers continue to be motivated by eco-friendly technologies, environmental awareness and energy efficiency regulations. Material innovation is one of the key strategies to reduce environmental impact moving forward. Concerns include energy consumption in manufacturing, waste generation, emissions from lubricants and raw material extraction. The end goal is to provide longer-lasting components with less waste.

The SKF Lincoln SL-6 metering device is a single-line automatic lubrication system injector. Its proven design is thoroughly updated to meet new demands on maintainability, leakage-protection and long-lasting performance even with harsh extreme pressure greases. Today’s manufacturing environment demands less maintenance time, higher productivity demands and little to no tolerance for unplanned production stops.

.

Pack Expo Las Vegas, one of North America’s most comprehensive packaging and processing events is celebrating a milestone: 2025 marks 30 years since the show’s debut. Today, Pack Expo Las Vegas continues to be a global hub for industry innovation and collaboration. Show producer PMMI, The Association for Packaging and Processing Technologies, has elevated Pack Expo Las Vegas from a regional trade show to a global industry force—expanding its scale, influence, and relevance across international markets. This year, the show spanned over 1 million net square feet, featuring 2,300+ exhibitors.

.

An innovative technology for the next generation of high-speed, high power density traction and propulsion systems has been jointly developed by Drive System Design (DSD) and Transense Technologies. David Hind, principal engineer, DSD, presented “Unlocking Powertrain Power Density with Innovative Motor Control,” earlier this year at the CTI USA Symposium 2025 in Novi, MI. The presentation built on initial simulation studies performed in MATLAB Simulink; a software tool used to design and simulate systems before moving to hardware. While simulation trials proved successful, achieving quality experimental results proved far more challenging. Hind examined these challenges and potential solutions at CTI.

.

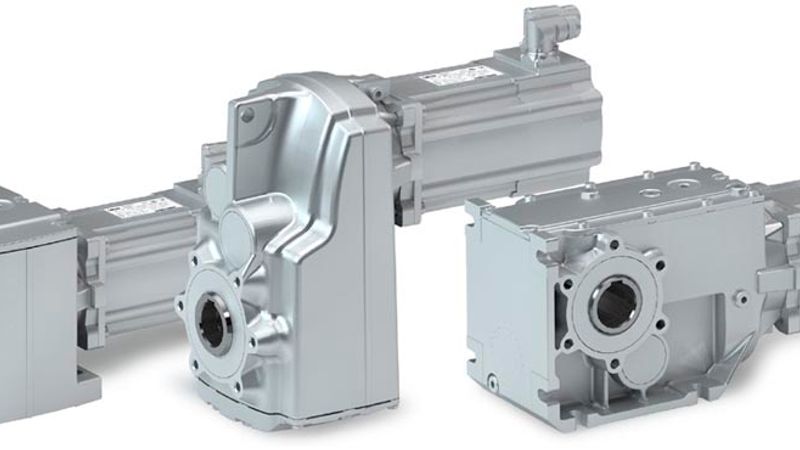

Atlanta Drive Systems, Inc., Farmingdale, NJ, offers rack and pinion systems, actuators, gearboxes, servo reducers and lubrication systems for many different industries including machine tool, automation, aerospace, woodworking, material handling, robotic, food, packaging, stone and special machinery. PTE recently discussed the company’s lubrication solutions with Peter Alfano, senior applications engineer.

.

The digital transformation is fundamentally changing the industry, and digital twins play a central role. They enable real-time monitoring of physical systems, simulation of their behavior, and informed decision-making. A dissertation from the TU Darmstadt Institute for Product Development and Machine Elements (pmd) shows how the FVA-Workbench gearbox design software can be implemented as a platform for creating digital twins of industrial gearboxes. The results demonstrate how the combination of detailed modeling, continuous real-time calculations, and engaging dashboard visualization offers an efficient and user-friendly solution for the development of digital twins.

Schaeffler continues to advance key technologies shaping the future of mobility and motion. One area of interest—humanoid robots—is where Schaeffler is developing advanced component and system capabilities for the next generation of robotics. PTE recently had the opportunity to discuss these technologies with Al Makke, engineering director, humanoid robotics, North America, at Schaeffler Group USA.

Technical sales personnel use intelligent features to select suitable motor-gearbox combinations and run calculations based on customer-specific operating data. This provides obvious added value for the customer. Service lives, safeties, and expected loads can all be determined in a short time. Maintenance of the underlying database and the use of simulation tools make it possible to quickly and easily perform technical calculations without having to rely on a central calculation department. In less than a minute, the customer is provided with a data sheet which includes reliable statements about the gearbox based on these technical calculations.

The Simplicity self-lubricating linear plain bearings are built to last, and they will often out-perform and last longer than a traditional linear ball bearing. Called the “little red bearing” by loyal customers, they have been a popular replacement for failing ball bearings. Simplicity plain bearings will not catastrophically fail.

The difference between a smooth-running drive and constant headaches? The right timing belt and pulley plus a whole lot more. Discover what works, what doesn’t, and put your design skills to the test—engineer your best system yet!

Discover how Regal Rexnord’s Bauer™ PMSM gear motor helped a transportation company streamline inventory, cut energy use, and save $80,000 annually. Learn how this scalable solution delivers financial, operational, and sustainability gains across facilities.

Design engineers are always on the lookout for efficient and reliable application solutions. While standard products often suffice, some challenges demand a custom approach. Custom machine couplings, critical for torque transmission between a machine's driving and driven components, require careful consideration of specific requirements to guarantee optimal performance and unwavering reliability.

Precision elastomer insert couplings offer vibration damping, easy installation, zero backlash transmission, and electrical isolation. Fitting a wide variety of drive applications including lift systems, conveyors, pumps, linear actuators, and high performance general power transmission.

With the goal of building a full lineup of actuators for every joint required in robot construction, Bonsystems has been developing robotic actuators and introducing the BCSA V4 Series. The BCSA Micro Series is a Cycloidal Micro Actuator designed specifically for robotic hands.

Jan 19, 2026

The Society of Tribologists and Lubrication Engineers (STLE) announces that registration is now open for the 2026 STLE Annual Meeting & Exhibition: Innovating Through Tribology & Lubrication, May 17-21, 2026, at the Hyatt Regency New Orleans. The STLE community and global tribology and lubrication engineering experts will gather for five days of technical training, industry education and business networking at the meeting.

Whether it’s moving a coil of sheet steel to a stamping line or setting a massive cast iron forging onto the bed of a CNC boring mill, manufacturers depend on cranes, trolleys, and hoists to lift and transport heavy objects. This is the job of OMi Crane Systems, a company that’s been designing, building, and servicing industrial lifting systems since 1969.

Apr 23, 2026 - Apr 25, 2026

In an era defined by economic uncertainty, supply chain disruption, and rapid workforce change, senior manufacturing leaders need more than tactical updates—they need strategic clarity. The 2026 MPMA Annual Meeting held at the Sunseeker Resort in Charlotte Harbor, FL, is designed specifically to deliver that clarity. Hosted by the Motion + Power Manufacturers Alliance (MPMA), this member-only gathering convenes top executives from across the power transmission and motion control industry for high-level dialogue, peer connection, and forward-looking insight.

Feb 17, 2026 - Feb 19, 2026

Mar 3, 2026 - Mar 7, 2026

Current Issue

Current Issue

Archives

Subscribe

Buyer's Guide

Accessories Actuators Adjustable Speed Drives Bearings Belting & Belt Drives Brakes Chain & Chain Drives Clutches Controls Couplings & U-Joints Fluid Power Gear Drives Gear Manufacturing Services Gears Industrial Hardware and Machine Parts Linear Motion Devices Lubrication Motors Resources Seals Sensors Services SoftwareThe Power Transmission Engineering Buyers Guide is your complete directory of suppliers of mechanical power transmission components, including great companies like these.

VIEW ALL