Greetings 2026! As expected, EV demand has waned following some deregulation and tax credits being dropped as of September 2025. For us industry folks, this is simply reality catching up with the narrative. On the plus side, 2025 was a very good year for global vehicle sales–the best since 2019 (Ref. 1). A good economy can forgive many blunders. As gearbox designers, our work continues as our EV offerings are likely a permanent part of our product lineup, even if at a reduced volume. When it comes to single speed offset gearboxes, many OE’s have a similar 3 parallel shaft design, running ratios typically between 7:1 to 15:1. Some higher speed boxes are going above 20:1 ratio now, but the basic architecture is unchanged. The Tesla design shown here is a common baseline design:

Operating for long hours, under extreme loads, in high temperatures and dusty environments, ongoing wear is a significant challenge for open gears. This can lead to unplanned downtime and reduced equipment life—creating a barrier to effective operations. Leading mining and cement companies use advanced grease technology and technical inspections to help prevent open gear failure, optimize service life and ensure the smooth running of their operations.

.

Consider the following scenario: guided by vision sensors, a robot spots a product on a moving conveyor, determines its exact position and, in one fluid motion, picks it up and places it into a waiting assembly, carrier tray, or shipping container. What human operators once found tiring—or at least tedious, the robot performs flawlessly, hour after hour, even long after its flesh-and-blood coworkers have gone home for the evening.

.

Despite a lukewarm sustainability agenda here in the United States, global bearing manufacturers continue to be motivated by eco-friendly technologies, environmental awareness and energy efficiency regulations. Material innovation is one of the key strategies to reduce environmental impact moving forward. Concerns include energy consumption in manufacturing, waste generation, emissions from lubricants and raw material extraction. The end goal is to provide longer-lasting components with less waste.

.

Bosch Rexroth continues to expand the ctrlX platform with new capabilities and automation enhancements. The control platform ctrlX COREplus is now available with AI functions on all performance levels. In the area of motion and drives, Bosch Rexroth is presenting compact, energy-efficient, and cabinet-free drives from the ctrlX DRIVE portfolio, which cover virtually all performance ranges. These are complemented by the Motion, CNC, and Robotics software ctrlX MOTION, which is ideal solution for automating production machines and systems. PTE recently had a great conversation with Garrett Wagg, product manager, controls at Bosch Rexroth on new developments in mobile robotics.

.

Half a million global visitors visit Aiguille du Midi as an access point for skiing in the winter and hiking, rock climbing and paragliding in the spring, summer, and autumn seasons. The mountain—part of the French Alps—boasts the current title of employing “the world’s highest vertical ascent cable car.” This unique transportation takes passengers from 3,396 to 12,605 ft. above the clouds. The planetary gearboxes needed for the cable car operation are provided by CMD Gears.

Schaeffler continues to advance key technologies shaping the future of mobility and motion. One area of interest—humanoid robots—is where Schaeffler is developing advanced component and system capabilities for the next generation of robotics. PTE recently had the opportunity to discuss these technologies with Al Makke, engineering director, humanoid robotics, North America, at Schaeffler Group USA.

Demand for specialty wire and cable—fueled in part by data center expansion as well as new charging stations for electric vehicles (EVs)—is in turn creating greater demand for cable production capacity. As you design machines that will satisfy the demand, you’ll want to incorporate an effective driving method that controls speed and torque with the highest precision.

The drive system choice is dependent on key motion features of your application. Lead screws offer self-locking capabilities, while ball screws require brakes to prevent back-driving. The choice between them hinges on efficiency, cost, precision, and speed, with the screw drives themselves paired with a linear guide for optimal performance.

Bellows couplings are commonly used in applications requiring precise rotation, high speeds, and dynamic motion transmission. With zero backlash and a high level of torsional stiffness, they offer clear performance advantages in many servo-driven systems.

The Simplicity self-lubricating linear plain bearings are built to last, and they will often out-perform and last longer than a traditional linear ball bearing. Called the “little red bearing” by loyal customers, they have been a popular replacement for failing ball bearings. Simplicity plain bearings will not catastrophically fail.

The difference between a smooth-running drive and constant headaches? The right timing belt and pulley plus a whole lot more. Discover what works, what doesn’t, and put your design skills to the test—engineer your best system yet!

Discover how Regal Rexnord’s Bauer™ PMSM gear motor helped a transportation company streamline inventory, cut energy use, and save $80,000 annually. Learn how this scalable solution delivers financial, operational, and sustainability gains across facilities.

Forest City Gear manufactures extremely high-precision gears made for the most advanced robotics, right in Roscoe, IL. This family-owned team of gearheads specialize in high-precision gears engineered to handle the most demanding robotic applications—on Earth, and way beyond.

Mar 3, 2026

The Motion + Power Manufacturers Alliance (MPMA) and the Alliance for Innovative Energy, LLC, managing and operating contractor for the U.S. Department of Energy’s National Laboratory of the Rockies (NLR), have signed a Memorandum of Understanding (MOU) to formalize their collaboration on advancing standards for gear and bearing design and manufacturing.

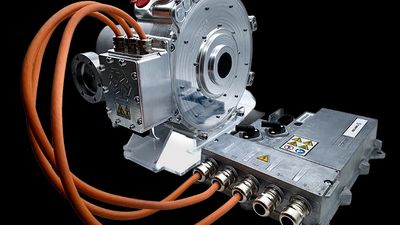

Turntide Technologies (Turntide) will unveil the Turntide Axial Flux Electric Drive Unit (EDU) during CONEXPO-CON/AGG (CONEXPO). This Axial Flux EDU provides electric and hybrid system manufacturers of any size with a configurable, proven and scalable platform that can remove months, if not years, of component-level testing, decreasing time and cost to market.

Jun 1, 2026 - Jun 4, 2026

Cleanpower 2026 (Houston) grows businesses by gathering key decision makers and stakeholders across the wind, solar, storage, hydrogen, and transmission industries for discussion, deal making, networking and a whole lot of fun.

Jun 15, 2026 - Jun 18, 2026

Mar 17, 2026 - Mar 18, 2026

Current Issue

Current Issue

Archives

Subscribe

Buyer's Guide

Accessories Actuators Adjustable Speed Drives Bearings Belting & Belt Drives Brakes Chain & Chain Drives Clutches Controls Couplings & U-Joints Fluid Power Gear Drives Gear Manufacturing Services Gears Industrial Hardware and Machine Parts Linear Motion Devices Lubrication Motors Resources Seals Sensors Services SoftwareThe Power Transmission Engineering Buyers Guide is your complete directory of suppliers of mechanical power transmission components, including great companies like these.

VIEW ALL