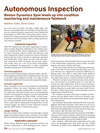

Autonomous Inspection

Boston Dynamics Spot levels up into condition monitoring and maintenance fieldwork

For a few years now, Spot—the agile, mobile robot—has been surveying show floors at Automate, CES and Promat. Last year, Boston Dynamics presented a slew of additional technologies at IMTS 2024, showcasing robotic innovations key to scaling autonomous industrial inspection for components such as bearings, motors, pumps, gearboxes and conveyor systems.

Industrial inspection

Many PTE readers have discussed employing AI technologies to tackle shop floor challenges in the coming years. An AI-enabled facility allows management to make better, faster decisions, improve safety and efficiency, and most importantly, reduce overall costs. Boston Dynamics believes the key to this evolution is capturing consistent and reliable data. These robots can now work with minimal variations to deliver frequent and accurate inspection results. Here are a few of the latest technologies, giving companies an opportunity to reduce unplanned downtime and prevent critical failures in the future:

Thermal inspection

Spot can collect thermal images of pumps, motors, and electrical equipment with pixel-level temperature data. Users can set up alerts when equipment exceeds a set range or when temperature differences between assets surpass thresholds.

Acoustic inspection

Noise anomalies can be an early indicator of impending equipment failure, but leaks, vibrations, and electrical discharge are typically undetectable by people. Acoustic inspections with Spot enable users to autonomously monitor sound signature changes to prevent unscheduled maintenance. Utilizing the Fluke Sv600—a fixed acoustic imager translating sounds into a visual representation to locate problem areas in factory systems—Spot can locate costly leaks in compressed air and gas lines, record acoustic images and videos for post-inspection analysis and alert MRO teams to maintenance issues.

Gauge reading

Spot uses machine vision models to read and analyze analog gauges that measure pressure, flow, and more. It can trigger alerts for abnormal readings and track asset trends over time.

Application examples

Nestlé Purina deployed Spot to automate thermal and acoustic inspections in their packaging lines. Autonomous inspections allowed Nestlé Purina to give time back to the maintenance technicians, better predict and plan repairs, and ensure reliable operations.