Buyer's Guide

Company Profile

Contact Information

Contact: Andrew Lechner

Phone: (630) 521-9911

Fax: (630) 521-0366

Email: Click here to see email.

Website: http://www.rw-america.com

Location

R+W America

254 Tubeway Drive

Carol Stream IL 60188

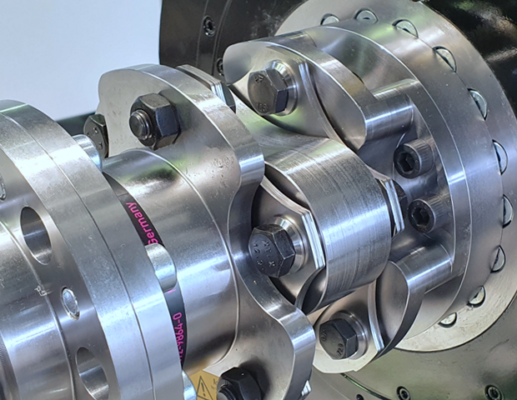

Engineering and manufacturing of precision flexible shaft couplings for motion control and power transmission applications, with a wide variety of designs for torsional rigidity, vibration damping, and overload protection. Whether for micro motors or 10 megawatt drives, couplings are customizable for most applications, while many standard models ship from stock. Configurable CAD models are available in a large number of file formats online.

Engineering and manufacturing of precision flexible shaft couplings for motion control and power transmission applications, with a wide variety of designs for torsional rigidity, vibration damping, and overload protection. Whether for micro motors or 10 megawatt drives, couplings are customizable for most applications, while many standard models ship from stock. Configurable CAD models are available in a large number of file formats online.

With a philosophy of meeting customer requirements from concept to production, R+W has supplied many thousands of custom coupling designs, creating a wealth of knowledge about the technical requirements associated with a wide variety of industries and applications. Constant new product development takes place in house, in addition to intensive collaboration with universities and engineering firms, keeping R+W at the forefront of technical development and product innovation in its field. Over the past 30 years this has resulted in a position of market leadership for metal bellows couplings, and global availability for all of its precision couplings and torque limiters.

New for 2021 is the intelligent coupling series. This product line will integrate measurement electronics into R+W’s existing coupling designs, offering users much better visibility and understanding of their drive system performance. Information such as speed, torque, and axial compression are streamed live to a proprietary app to provide useful real-time data. The integral battery allows for continuous usage of up to 5 days, with an inductive charging design still in the works for 2021. This coupling can also be integrated into customer’s existing controls systems via a gateway converter, making installation and data management even easier. The future of couplings has arrived and is ready for Industry 4.0.

Articles

Whitepaper

Precision Line Shafts - More Widely Used Thanks to Localized Production

R+W America

Read More