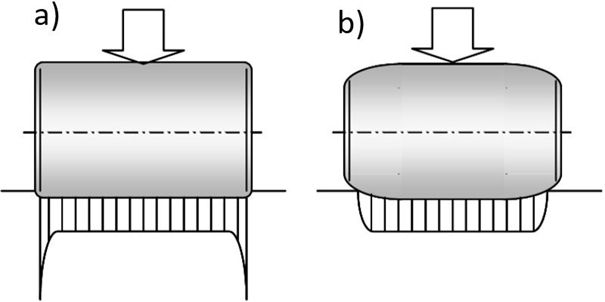

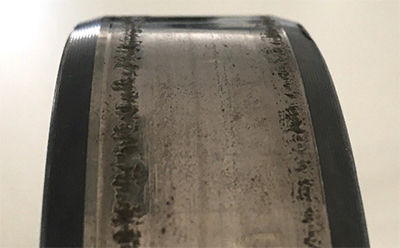

In roller bearings, there is line contact between the rolling elements and the raceway. If the rolling elements are perfectly cylindrical (cylindrical roller bearings) or tapered (tapered roller bearings), this leads to local pressure peaks when the end side of the rolling elements comes into contact with the raceway (Figure 1a). This can result in local pitting damage in these areas (Figure 2). To avoid these pressure peaks, roller bearings are always designed with profiling along the longitudinal axis of the roller (Figure 1b). In addition to avoidance of high edge stresses, the profiling also has an influence on the following criteria:

- Maximum roller-raceway contact pressure, especially with tilting

- Modified reference rating life according to /2/

- Tilting and lowering rigidity

Figure 2 Local pitting as a result of profiling created by wear.

Cylindrical and tapered roller bearings typically have a logarithmic profile in accordance with /2/. However, the actual depth and shape of the profiling can deviate significantly and is determined by the manufacturer, based on available knowledge for each bearing type. In order to consider the influence of different profiles on the above criteria in the bearing design phase, the FVA-Workbench provides the option to adapt the profile for each individual roller bearing. In addition to pre-defined profile shapes, profile curves provided by the bearing manufacturer or based on measurements can also be defined. Therefore, it is recommended to consult the bearing manufacturer in critical cases when making the final bearing selection.

Calculation Example

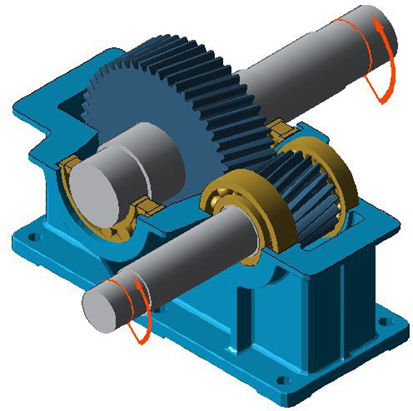

Figure 3 Example gearbox.

The influence of different profiles will be demonstrated, using the calculation of the NJ 230 type motor-side output shaft bearing from the gearbox shown in Figure 3 as an example. Three different profile variations are calculated for the bearing:

- 32 µm logarithmic profile (corresponding to /2/)

- 14 µm logarithmic profile

- No profile

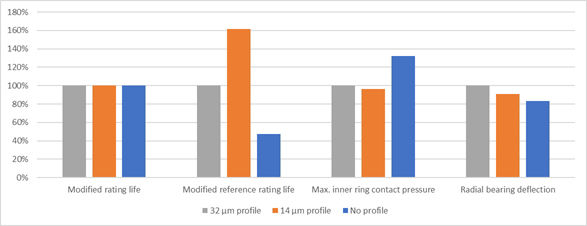

Diagram 1 provides an overview of the calculation results for the 3 variants. The values are all relative to the corresponding profile specified in /2/ (here: 32 µm).

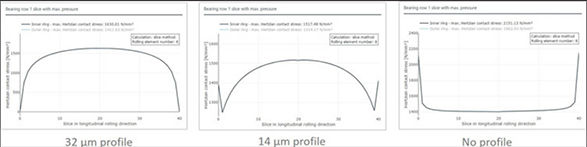

Additionally, the pressure distribution along the longitudinal axis of the roller in the inner ring contact of the most heavily loaded roller element is compared for the three variants in Figure 4.

The following statements can be derived from the results:

- The profiling has no significant influence on the results of the modified rating life calculations (according to both ISO 281 and bearing manufacturer catalog calculations). Only minor differences may result from the fact that slightly different bearing forces may be calculated in the system due to the change in the bearing stiffness.

- The distribution and the maximum value of the local contact pressures in the bearings are decisively influenced by the specification of different profiling. From the curves in Figure 4, it can be seen that the pressure in the middle of the roller increases with higher amounts of profiling. With lower amounts of profiling, the pressure distribution becomes more even. In this case, however, increased edge stresses may occur, especially at high tilt angles.

- Since the value of the modified reference rating life according to DIN 26281 is based on consideration of the local contact pressure, a strong influence on the rating life values can also be seen here for each specified profile.

Diagram 1 Comparison of the calculation results for different amounts of profiling.

Figure 4 Comparison of the pressure distributions of the most heavily loaded rolling element.

About FVA GmbH:

FVA GmbH is a joint venture of VDMA (Verband Deutscher Maschinen- und Anlagenbau, the Mechanical Engineering Industry Association) and FVA e.V. (Research Association for Drive Technology). Founded in 2010, FVA GmbH works hand-in-hand with top-level German research institutions and leading companies from the drive technology industry toward the practical application of knowledge gained from FVA research projects. Our core competencies are the development of calculation and simulation software for drive technology, processing and conversion of legacy code structures into modern software architectures, professional service and support, and hosting technical seminars and conferences (www.fva-service.de #FVAWorkbench #FVADriveTechnology).

M. Sc. Benjamin Abert is Head of Consulting & Service, FVA GmbH. He studied at the TU Clausthal. He began in 2013 at FVA-GmbH as calculation expert for plain and rolling bearings. Since 2018 his responsibility is expert support and sales.

M. Sc. Benjamin Abert is Head of Consulting & Service, FVA GmbH. He studied at the TU Clausthal. He began in 2013 at FVA-GmbH as calculation expert for plain and rolling bearings. Since 2018 his responsibility is expert support and sales.