“This will certainly drive technology implementation and different degrees of electrification. The off-highway market being very fragmented makes it difficult to speak in general terms, however we expect diesel engines to remain predominant in the mid-term, and VVA technologies to play an important role to enable OEMs to meet the new regulations. As mentioned above what makes VVA stand out from the alternatives is that it provides benefits on both the NOx and CO2 front,” Contarin said.

All of this matters because of the number of off-highway vehicles there are vs. on-highway.

“Perception is it is a niche market, but in reality, it’s not. In 2020 4.3M engines were produced for off-highway applications while 3.5M were manufactured for on-highway. So making them cleaner is just as important,” he concluded.

www.eaton.com

Heavy-Duty Drivetrains with Dana

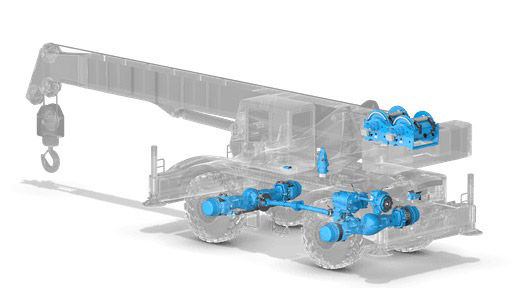

Performance upgrades are essential for rough terrain cranes in the off-highway market.

The Spicer 246 heavy-duty steer axle and Spicer C3300 remote torque converter are offered as part of a complete drivetrain solution for rough-terrain cranes that delivers premium performance through improved gradeability and travel speeds, higher efficiency in the field, increased productivity, and reduced operating costs.

“As the global construction market recovers, buyers are looking for high-performing vehicles that deliver exceptional productivity and efficiency,” said Aziz Aghili, president of Dana Off-Highway Drive and Motion Systems. “Dana’s large and growing capabilities for rough-terrain cranes enable us to anticipate market shifts and collaborate with original-equipment manufacturers to supply the drivetrain technologies that improve their competitiveness.”

Dana’s new heavy-duty Spicer 246 steer axle features a monolithic axle design and high integrity seals that deliver exceptional performance in the most severe working conditions. It features optimized steering geometries to minimize slippage, while the single universal joint design with outboard planetary gears provides high output torque and high-capacity braking with low drag at travel speeds.

Currently available for OEM field testing, the Spicer 246 axle can also be adapted for use with airport ground support vehicles, where it can be configured with optional wet brakes.

Dana has also developed the new Spicer C3300 remote torque converter specifically for rough-terrain cranes. It is optimized for engines up to 195 kW (260 hp) and can be packaged with Spicer remote transmissions. Dana is the only manufacturer worldwide that supplies a remote torque converter with three large pump drives for implements.

The Spicer C3300 remote torque converter is available with an optional lockup that improves efficiency while providing higher braking effort during downhill operation. It features new converter wheel sizes configured to optimize the performance of today’s low-RPM engine designs.

Available now, the Spicer C3300 remote torque converter is already in use in terminal tractor applications, where it enables lower heights for fifth wheels.

Dana has anticipated market shifts with its latest drivetrain technologies.

Dana has a large and growing selection of drive and motion technologies for manufacturers of tracked and wheeled cranes.

Earlier this year, Dana introduced a new series of Spicer Torque-Hub drives for crawler cranes and other large-tracked vehicles. With torque ratings from 80,000 N-m up to 450,000 N-m, the new drives offer flexible packaging and gear ratios to meet manufacturer preferences for tracked and wheeled applications.

Also, Dana offers high-performance Brevini winches for cranes and other applications with lift capacities from 1.1 tons (990 kg) to 33 tons (30 tonnes).

Additionally, Dana supports the work functions of cranes with a wide selection of Brevini slew drives, hydraulic pumps and motors, and proportional directional valves.

www.dana.com

BorgWarner Powers Commercial Vehicles with HVH 320

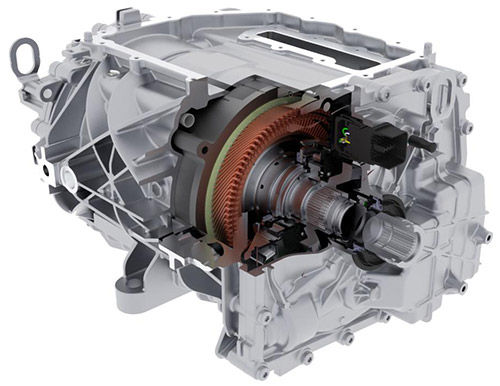

BorgWarner’s High Voltage Hairpin (HVH) electric motor, the HVH 320, can power a variety of hybrid and electric applications for commercial vehicle manufacturers

BorgWarner’s High Voltage Hairpin (HVH) electric motor, the HVH 320, can power a variety of hybrid and electric applications for commercial vehicle manufacturers, including a large European OEM. Production of the HVH 320, which is equipped with 800-volt capabilities and available in four variants, is expected to kick off in 2024. Its multi-faceted platform will support the manufacturers’ goal of a common electric drivetrain and deliver approximately 97% peak efficiency and over 400 kW of power.

BorgWarner leveraged its motor production experience to design four variants of its modular and flexible HVH 320 motor platform to meet the customer’s requirements. The motor offers clean and quiet operation, while reaching a torque output of up to 1270 Nm. Also, the technology supports the vehicle’s shifting sequence and charges the battery by generating power while braking or driving downhill.

The HVH 320 motor is the newest addition to BorgWarner’s portfolio of HVH series motors, which are offered to both light-duty passenger cars and heavy-duty commercial vehicles. These versatile motors feature patented stator winding technology, are easy to integrate and are available as fully housed motors or as rotor/stator assemblies. Additionally, the motors can be used in a variety of architectural positions throughout a vehicle. BorgWarner also offers inverters that can achieve the same, next-generation 800-volt level.

“Adding the HVH 320 to our electric motor family bolsters our offerings and is an excellent example of BorgWarner’s commitment to delivering state-of-the-art clean propulsion technologies that match market needs,” said Dr. Stefan Demmerle, president and general manager, BorgWarner PowerDrive Systems. “Using our 800-volt rated machine, customers can significantly reduce charging time and achieve a higher power density, enabling an even brighter future for electric trucks.”

www.borgwarner.com

Thomson Offers H-Track Electro-Hydraulic Linear Actuators

H-Track actuators from Thomson Linear incorporate a patented fluid power design, which provides high load capability for extreme duty use.

Designers for heavy duty motion control applications have traditionally specified hydraulic cylinders for their high speed, heavy load handling and resilience. However, recent advancements that embed hydraulic technology within electric linear actuators have been delivering the benefits of hydraulics without the common drawbacks.

H-Track actuators incorporate a patented fluid power design, which provides high load capability for extreme duty use, a more compact pin to pin than other actuators of the same load capability, excellent ingress protection and corrosion resistance. The H-Track uses an external gear pump connected to a reservoir and actuator, yielding the most impact resistant.

Warner actuator. The H-Track pump is burnished, cleaned, flushed and vacuum filled with degassed hydraulic fluid. The system is completely sealed with no hoses to leak. This ensures you receive contaminant free and maintenance-free product for the life of the actuator.

The H-Track electro-hydraulic linear actuator is an all-in-one, self-contained system that can tolerate extreme shock loads, prevents leaks and features a higher speed profile. It allows personnel to avoid the messes, complexities, contaminants, and maintenance associated with traditional hydraulic cylinders. For more information regarding these innovations download Thomson’s white paper, “Why Electric Actuators are Increasingly Replacing Hydraulic Systems,” here:

www.thomsonlinear.com/en/products/linear-actuators/white-paper