“Compared to pneumatic or hydraulic cylinders, the advantage of linear motion products and linear actuators used in aerospace applications has greatly increased accuracy and repeatable operation. The inherent advantage of the electrical motors is the mechanical connection between a nut and screw versus a pump compressing a fluid and then pressing against a plunger. There is always more variability in fluids and flows than in electricity and mechanical connections. If you are trying to precisely move the flaps on an airplane wing or the fins on a missile, this level of mechanical accuracy is critical for flight surface control.”

Along with added accuracy and control, enhanced field performance is propelling liner motion into the forefront of aerospace applications. Lead screws feature a unique thread that maintains a tighter, more rigid contact angle, resulting in lower contact stresses, higher load carrying capacity, reduced wear, optimum thrust control, and maximum predictable life. In addition, material selection specifically made for strength and durability — like high-strength steel, bronze or engineered high-PV plastics — offer proven dependability in rigorous and demanding environmental conditions and speeds. Lead screws also offer the opportunity to apply dry lubricants to reduce the maintenance frequency and increase the life of the overall assembly.

Select lead screw manufacturers also produce their own thread rolling dies and design custom thread forms when specific linear motion rates, speeds and forces are required. This in-house capability can offer shorter lead-times for prototype parts as well as reducing the risk of down time when rolling dies need to be replaced due to wear.

Lead screws perform optimally in a wide range of temperatures, from -50° to 140°F, when the design incorporates thermal expansion. High forces are also well-managed by selecting appropriately high tensile lead screw nut materials like bronze and high-PV polymers. Nuts manufactured from bronze or polymers combined with glass or Kevlar can be utilized with a PTFE coating on the screw as a dry lubricant. PTFE coatings can increase the life of lead screw nuts by up to ten times.

Design Flexibility

The versatility and design flexibility afforded by using linear motion components like lead screws, liner guide rails, and electric linear actuators provide flight engineers with design freedom that was not previously possible. Lead screw nut design can be maximized to efficiently incorporate other components, reducing part counts and simplifying designs. Threaded inserts can be added to the nut design using ultrasonic welding or using inserts welding processes. Lead screws can also be manufactured from a wide array of materials to meet the specific aerospace requirements, including:

- Titanium

- Stainless Steel

- Aluminum

- Engineered plastics

- High strength Alloys

- Bronze

Figure 2: Hollow lead screws help to reduce overall weight of the actuation system; gear nuts also increase system rigidity.

These materials can also be utilized to manufacture hollow screws for weight reduction purposes and have custom-machined ends to accommodate bearings, pulleys, couplings, motors, and other assembly components.

Linear motion applications in this industry are widespread. Several common examples include:

Missile fin actuation. Precision-engineered miniature lead screw assemblies replace hydraulic and pneumatic actuators formerly used in these instances. Each lead screw and nut combination converts torque to thrust as the screw or nut turns, moving the mated piece in a linear direction. In addition, the lead screw mechanism eliminates sliding friction and stick-slip, therefore requiring little or no maintenance after initial lubrication. Lead screws automatically minimize the power required to drive missile-fin actuation due to their high efficiency. The size and weight of the fin drive transmission are also reduced, making lead screws a better option for small missiles and targeted munitions.

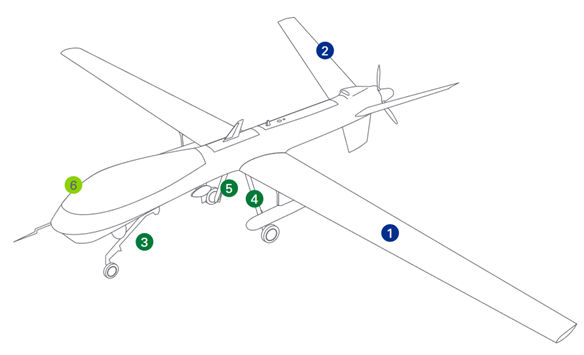

Unmanned aerial vehicles. The global UAV drone market is poised for rapid growth fueled by increased use of UAVs/drones in the military and defense industry. Fixed-wing sub-segments and military and defense sub-segments are estimated to lead the market. Lead screws and lead screw- driven actuators are quickly becoming a solution of choice as a product of their performance options and the speed to market for custom solutions.

Figure 3: The lead screw mechanism eliminates sliding friction and stick-slip, requiring little or no maintenance after initial lubrication.