Gearmotors: The Art of Precision and Reliability

High performance, high precision and component compatibility top the list of gearmotor trends in our product-roundup for 2022. These products can be found in everything from AGV and mobile robotics to solar power, aerospace and large optical systems. Additionally, Automate 2022 will feature several gearmotor providers in Detroit later this year. Be sure to check back frequently to the PTE website for the latest product, industry and technical content in these areas.

Faulhaber Focuses on High Speed and Dynamics

The multi-pole, two-phase AM3248 stepper motor performs 48 steps per revolution and offers a very high holding torque of 85 mNm. The motor starts with a high speed from the very first step; thanks to its low inertia, it can be used in applications that require very fast acceleration and fast changes of direction. Newly developed large ball bearings further extend the already long service life of this motor type.

The motor is ideally suited for a variety of demanding applications. This includes aligning the solar panels of satellites, for example. The motors move the booms so that the panels are always directly facing the sun. In addition to working precisely and reliably over many years, the motors must also be able to withstand the extreme temperatures in outer space. In the semiconductor industry, very high dynamics and speed are required when positioning the wafers in very confined installation conditions in the machines. This is another application in which the highest level of precision and reliability are essential.

"Our new AM3248 model meets all requirements and is ideally suited for high-performance applications of this kind," explains Thomas Würgler of Faulhaber Precistep. The corporate unit specializing in stepper motors is located in the Swiss city of La Chaux-de-Fonds, known for its watchmaking. "We are able to adapt the product to the requirements of the respective application, even in small production runs. We provide our customers with the entire drive package, including technical advice and support from a single source.” Learn more here: www.faulhaber.com

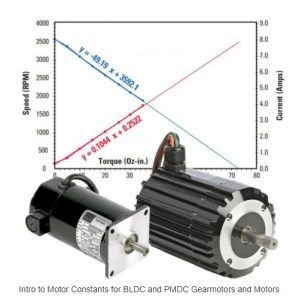

Motor Constants with Bodine Electric Company

Common Motor Constants:

The most commonly used motor constants are Torque Constant (Kt), Voltage Constant (Ke), Electrical Time Constant (Te), Mechanical Time Constant (Tm), and Thermal Resistance (Rth). Typical values for these constants are derived by using measured values of No Load Speed, No Load Current, Stall Torque, Circuit Resistance, Circuit Inductance, and Armature Inertia with the following equations:

Torque Constant (Kt) — describes the proportional relationship between torque and current. Kt is usually expressed in the units Oz-in./Amp. Learn more here:

https://www.bodine-electric.com/blog/bodine-gearmotor-constants/

AutomationDirect SureStep Motors Extend Torque Range

https://library.automationdirect.com/larger-stepper-motors-now-available-at-automationdirect/

Brother’s DC Gearmotors Suitable for Robotic Applications

https://www.brother-usa.com/business/gearmotors-and-reducers/brushless-dc-gearmotors

Automate 2022

“Interest in robotics and automation overall is clearly at an all-time high, with robot orders breaking records,” said Jeff Burnstein, president of A3. “Companies from nearly every industry, from automotive manufacturers to aerospace, life sciences, pharmaceuticals, medical device, warehousing, metals, electronics, food and consumer goods, know they need to automate to succeed, even more so as they struggle with labor shortages and supply chain issues. With more than 350 exhibitors already signed up, Automate is the place to be for individuals and enterprises wanting to learn about the latest technologies and strategies that will help them reach their goals.”

Register for Automate 2022 here: https://www.automateshow.com.