Hannover Messe 2.0

(Main image courtesy of Deutsche Messe, 2018)

Hannover Messe 2019 will focus on the integration, digitization and interconnection of industrial technologies transforming manufacturing today. The lead theme for Hannover Messe 2019 is “Integrated Industry – Industrial Intelligence.” For PTE’s original article visit: https://www.powertransmission.com/articles/0219/Hannover_Messe_2019/.

“Instead of the traditional focus on Oil profit and industry margins, we want to focus on the connection between humans and machines in the age of artificial intelligence, particularly regarding how people use algorithms to teach machines to operate intelligently,” said Arno Reich, senior vice president, industry, energy and logistics at Deutsche Messe AG. “This overarching theme covers topics such as Industry 4.0, Industrial Internet of Things, platform economies, cobots (collaborative robots), and cybersecurity.”

Exhibitors will show how manufacturers can use control technology and sensors to integrate automation technology, software and IT into electrical and mechanical drive systems. There will also be a strong focus on robotics. Hannover Messe takes pride in evolving with the changing needs of the manufacturing industry, according to Reich.

Booth Previews:

The following are additional booths PTE readers may be interested in if they’re attending Hannover Messe in Germany from April 1-5, 2019.

Schaeffler

Hall 22, Booth D43

Reducing Part Numbers for Gearbox Manufacturers

Gearbox manufacturers modularizing their portfolios implement different numbers of gear teeth, gear stages that can be combined flexibly, and varying numbers of planetary gears. The speeds and loads to which the relevant components such as gear teeth, shafts, and bearings are subjected change according to the application. Depending on the gearbox configuration in question and the associated requirements in terms of rigidity and load carrying capacity, bearings with different dimensions must then be implemented in a single bearing position, which brings with it a wide variety of housings, housing covers, gears, and shafts.

The objective of Schaeffler’s concept is to allow bearings of different designs but with identical dimensions to be implemented in one and the same bearing position for the various gearbox configurations. These “interchangeable gearbox bearing solutions” will be available based on dimension series 18 for high-precision servo planetary gearboxes, for example: FAG deep groove ball bearings from series 618, INA angular contact ball bearings from series 718, and INA SGL angular contact roller bearings allow the bearing support’s load carrying capacity, speed range, and rigidity to be adjusted while retaining the same design envelope. Out of the three variants, the INA SGL angular contact roller bearings offer the highest level of rigidity and thus allow extremely rigid bearing supports and drives with very high positional accuracy to be achieved.

The identical outside dimensions mean that special adapters and component variations (particularly for the shafts, housings, and housing covers) are no longer required and the associated development steps such as drawing modifications and NC programming in the manufacturing process can be omitted. The reduced range of gear, shaft, and housing variants means larger quantities, lower unit costs, and shorter delivery times.

The design envelope and rigidity requirements of planetary gears mean that they are often supported using cylindrical roller bearings without an outer ring. Both full-complement designs and designs with cages are used here depending on the required load carrying capacity and speed, but these bearings are not interchangeable because their envelope circle diameters are different. As a consequence, new planetary gears have to be designed, produced, and mounted. To make interchangeable bearing solutions available even for planetary gear bearing supports, Schaeffler’s design engineers have developed the INA RSLK1822, RSLK1830, and RSLK1850 cylindrical roller bearings with cages based on the dimensions of full-complement RSL bearings. These feature identical outside dimensions and can thus be used as replacements without any structural changes, design adjustments, or additional outlay in terms of time and costs.

Longer Machine Operating Times and Lower Maintenance Costs

Certain auxiliary equipment is prone to being forgotten once initial operation has been completed – including lubrication systems. If no unexpected failures occur, the lubrication intervals and lubricant quantities that were initially defined generally go unquestioned. In this context, a requirement and load-based lubricant supply – which can be achieved with Schaeffler DuraSense – offers enormous potential for extending machines’ operating times and reducing maintenance costs. The innovative system comprises a guide carriage with sensors that have been specifically developed for this application and an electronic evaluation unit that allows up to seven sensors to be connected for monitoring the guide carriage’s lubrication conditions. During a defined reference run during operation, the lubrication conditions for each guide carriage are continuously recorded from the vibration energy that is emitted, and these conditions are checked against a limit value known as the “lubrication indicator”. If this limit value is exceeded, relubrication takes place.

Schaeffler DuraSense provides three different ways of carrying out relubrication. In its basic development stage, the system can be used to monitor, assess, and if necessary optimize manual relubrication or interval lubrication systems. The Schaeffler DuraSense sensors and the relubrication system are independent of each other in this case.

In the automatic variation, the Schaeffler DuraSense sensors and the lubrication system are linked together in a single control loop. Fixed lubrication intervals are omitted and the lubrication system is activated only according to the lubrication indicator. Suitable lubrication systems include both Schaeffler products such as the Concept2 and Concept8 automatic lubricators and central lubrication systems, for example.

There are two ways in which lubricating impulses can be triggered. The first is for the evaluation unit to deliver 24V trigger signals for each of the seven channels. The 24V outputs can be connected to both the relubrication units and the machine control system. The second option allows the lubrication indicator value to be emitted as a 4-20mA signal for each of the seven channels as an alternative to the 24V signals. Using this variant makes it possible for lubrication conditions to be continuously monitored, the relubrication function to be adjusted with even greater flexibility, and the signal used for further analyses such as future remaining useful life calculations. In addition to the two analog outputs, Schaeffler DuraSense will also feature field bus protocols from the second half of the year onwards. Anybody can then configure the selection of the outputs as well as the type and number of carriages using a new software program. (www.schaeffler.com)

Voith

Hall 23, Stand B32

At the Voith booth, visitors can experience live how machine and plant operators can save up to 70% energy while increasing productivity. Under the exhibition motto "Progressive Hydraulic Solutions," Voith will showcase hydraulic complete solutions and products to control and manage machines and systems. The spotlight will be on the company´s CLDP and CLSP linear drives, as well as the servo drives and the IPS variable speed internal gear pump. Models of all products will be on display at the booth.

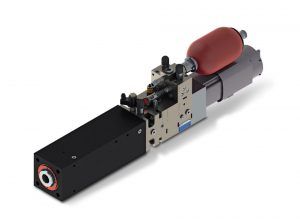

CLDP Servo Drives

CLDP servo drives are linear drives with hydraulic power transmission. This makes the drives nearly wear-free and gives them unlimited overload protection. They feature compact design and an integrated closed-loop hydraulic system. The servo drives have only a few electrical interfaces. No knowledge of hydraulics is required for installation and commissioning.

CLDP linear drives have been standardized. The large number of designs and sizes allows you to make a quick and ideal choice for your application. Time and effort for engineering the drive itself are unnecessary. Applications include almost any linear motion requiring high dynamics and precision.

Variable Speed Pumps, Servo Pumps

The future of hydraulics has arrived with Electric Submersible Pump Systems and variable speed pump systems. With these pumps, hydraulic systems are achieving a functionality never seen before. Servo pumps control the pressure or the volume flow. They precisely convert electrical energy into the hydraulic energy that is currently needed in the system. The classic use of valves for control can be either completely or partially omitted. This considerably simplifies every hydraulic system.

Customers give Voith all the cycle data for their machine or system. Voith engineers then use this information to determine the necessary pressures and volume flows, and design the pump systems. In the end, you get a complete solution – customized, ready to run, and all from a single source. (www.voith.com)

AMMEGA Group

Stand B30/C29, Hall 25

Both Ammeraal Beltech and Megadyne brands (under the AMMEGA group name) will exhibit together at this year’s Hannover Messe. Both brands have over 60 years of industry service, and their product portfolio spans custom solutions for such markets as food, packaging, elevators, material handling, fitness, and medical, as well as automotive, construction and heavy industry, robotics, and commercial and domestic appliances.

Key products will include Ammeraal Beltech’s Uni UltraFit Two-Part Sprocket System, the multi-directional Uni QNB Ball Belt, now widely employed in intralogistics, materials handling, packaging and manufacturing and the versatile Soliflex PRO positive-drive belting solution for bakery and foods, offering optimal hygiene; and their Maestro Splicing Tool for quick on-site results.

Megadyne will feature their versatile range – rubber and polyurethane timing belts, pulleys; rubber V belts and a variety of belting ‘add ons’ for different industrial applications. New products will be highlighted, including the Hybrid range for the hygiene, food and packaging industries that combine synchronous belts and conveyor belts; the new electric conductive Megapower EC belt; the special Megalinear ID belt, equipped with a microchip that can relay data to smartphones or other devices, and the Megawire solution for power supply to small motors for materials handling, in which the cords transmit power and electrical signals. (www.megadynegroup.com)

CoorsTek

Hall 3, Booth M03

Hall 22, Booth A33

CoorsTek will present the latest developments in technical ceramics during Hannover Messe 2019.

“We are pleased to support the semiconductor industry and its new requirements for energy-efficient sensing, automated devices, robotics and artificial intelligence,” said Andreas Schneider, executive vice president, Europe. “Our technical ceramics components are engineered to support virtually every step of the semiconductor manufacturing process – improving yields, increasing throughput and enabling smarter devices. This in turn enhances our customers’ competitive advantage and drives growth.”

CoorsTek will present the following new developments at the show:

CoorsTek is currently developing an unconventional shaping method to produce components with more complex features to support the industry’s growing need for bigger and more complex semiconductor components. These new molding and pressing technologies are easily scalable and ideal to support the semiconductor industry. The new CoorsTek shaping method allows customers to quickly adapt both their part design and production volumes according to the market needs.

CoorsTek recently developed molding methods allowing manufacturers to design parts with more complexity and additional features. This technology enables product designers to integrate multiple functions and decrease the number of components reducing manufacturing assembly phases and time-to-market.

More sophisticated semiconductor systems are demanded to fulfill growing needs for bigger data collection, data storage, and memory. CoorsTek is investing in its manufacturing sites and resources to meet the growing needs for high-purity alumina oxide semiconductor components in the US, Europe, and Asia. The Gumi, Korea facility expansion is the biggest coordinated expansion of operations in CoorsTek history, increasing the manufacturing capacity of the facility to over 9,000 sqm.

In addition, CoorsTek’s latest developments will help the automotive industry to drive performance and sustainability with the following new materials:

The silicon nitride (SiN) Cerbec bearing elements are especially valuable in applications where steel balls degrade rapidly or where electrical insulation is a necessity.

CoorsTek has developed two new SiN bearing grades, SN102 and SN103, to complete its existing bearing elements offer:

SN102 meets the requirements of ASTM F2094 Class I, and is especially suitable for high-contact stress applications such as machine tool and aerospace applications.

SN103 is suitable for medium contact stress applications such as electric motors, generators, and e-mobility applications. SN103 meets the requirements of ASTM F2094 Class II.

Visit Hall 3, Booth M03 or Hall 22, Booth A33 to learn more during the show. (www.coorstek.com)

Tsubaki

Hall 24, Stand B35 (16)

As well as products from its standard chain ranges, Tsubaki will be displaying large size roller and conveyor chain alongside several innovative products. The latter includes Tsubaki’s Zip Chain Actuators, in which two chains are locked together like a zipper to form a single, strong column for pushing and pulling applications.

Also on display will be a drive system that replaces gears and racks. Consisting of a pin wheel and rack, plus a gear with a unique tooth profile, Pin Gear Drive Units offer limitless design possibilities for rotating and linear drives.

Stand visitors may like the one-touch operation of Tsubaki’s new range of inspection doors or hatch covers for use with process plant and covered conveyors such as those used for transporting bulk materials. These easy mounting solutions offer protection from dust and moisture ingress, yet can be easily opened for visual checking of operations.

The newly enlarged range of Tsubaki’s chain wear indicators is expected to be a talking point amongst visitors. Robust and simple to use, one end of the indicator is shaped to fit snugly over a roller and the tip of the other end indicates the degree of wear by highlighting the total elongation over a number of links. The new indicators cover large size chain from BS RS20B to RS48B and ANSI from RS100 to RS240. These complement the existing sizes from BS RF06B to RS16B and ANSI RS35 to RS80. (tsubaki.eu)