Cooling Tower Components: Pros and Cons

Written by: Jerome Jennings, global product manager, SPX Cooling Technologies, Inc.

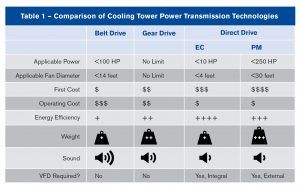

Cooling towers can use several power transmission technologies, including a gear drive, belt drive, direct drive, and electronically commutated (EC) drive. Each has advantages and disadvantages. The proper selection strikes an appropriate balance of initial cost versus operating costs.

Overview of available power transmission technologies

Gear drives offer moderate initial costs with low lifetime operating costs

In a cooling tower application, the gear drive reduces the high-speed power from the motor to the lower speed required to power the fan. The induction motor is relatively small because the gearbox multiplies torque.

Gear drives are effective at all cooling tower power levels. Their thick, casted shells housing the gear teeth and oil bath can withstand the high heat and humidity inside the cooling tower. Gearboxes require additional “no load” power to overcome the friction of internal components and oil viscosity. Net efficiency of the gearbox varies per application, but is generally near 96 percent.

The gear drive requires little maintenance. For example, some gearboxes using synthetic oil do not require an oil change for five years, but cooling tower owners and service contractors should be diligent about inspecting for potential leaks. Another positive feature of the gear drive is that it runs off direct online power. A variable frequency drive (VFD) is not required, but may be included for added motor speed control and energy use benefits.

Belt drives feature low first cost but higher operating cost

Belt drives have been around even longer than gear drives. They are used to transmit motion from one shaft to another with the help of a loop of flexible material, or belt, that runs over two sheaves (also called pulleys) to link the rotating shafts. This technology offers a smooth and effective transmission of power between shafts, even if they are at a considerable distance.In a cooling tower application, the size of the sheaves determines the speed; different sized belts provide the speed reduction required. The smallest sheave connects to the motor, while the larger fan sheave is connected to a fan shaft. The ratio between those sizes dictates the speed reduction. Belts matching the profile and length requirements of the sheaves transmit power.

Unlike gears, belt drives are exposed to the cooling tower’s hot, moist environment. The initial cost of a belt drive is low, but ongoing maintenance costs grow over time. Sheaves and other components corrode; belts stretch and lose tension. Starting at about 95 percent efficiency, belt drives can drop to the low 90s or even lower as the belts stretch and wear. Maintenance includes regular belt replacement and fan shaft bearing lubrication several times a year, contributing to its higher lifetime operating cost.

Belt drives are often employed in cooling towers with lower horsepower requirements. Like a gear drive, the belt drive does not require a VFD.

Direct drive motors have low maintenance requirements but initial cost is typically much higher than other alternatives

There are multiple direct drive options in which the motor directly drives the cooling tower fan. The direct drive motor offers reliability with minimal maintenance requirements.A common direct drive option uses a permanent magnet motor. This is a type of electric motor with rare earth permanent magnets incorporated into the rotor. Use of this technology has grown over the past decade and is now widely used in vehicles, drones, computers, and numerous other applications that need powerful but relatively compact motors.

The permanent magnet motor directly drives the fan, eliminating a number of components, including gearbox, driveshaft, pillow block bearings and couplings. This in turn eliminates the need for alignment of the mechanical components, speeding installation, reducing installation costs and increasing system efficiency.

One disadvantage of the permanent magnet option is initial cost – a direct drive with a permanent magnet motor is often the highest cost of all power transmission options. For the torque requirements of cooling tower applications, permanent magnet motors become heavier and taller than standard induction motors, due to elimination of the gear drive.

Permanent magnet motors require a VFD to operate. Although an extra initial cost, the VFD lets operators control speed and conserve energy.

A direct drive typically has the lowest maintenance cost over its lifetime because there is no need to replace the oil, no oil seals that can wear, and no need for routine alignment. Annual lubrication is recommended. Initial costs can be two to three times more than a gearbox. Due to the high first cost, payback can extend to 10 or more years.

Electronically commutated motor combines motor, controller and fan

Cooling towers that use EC motors are usually of smaller capacity and footprint with a maximum application size of 10 hp or one-meter fan diameters. Compared to belt drives and other low-horsepower motors (less than 5 hp), EC motors are consistently more efficient. In small-hp applications, the EC motor presents no power transmission loss while other low-hp motors and belt drives can experience power transmission losses from 5-20 percent.

Because EC motors use sealed bearings, there is virtually no maintenance. The use of this technology for cooling towers is new and currently lends itself only to low-hp, small fan diameters.

Selecting the right option is a balancing act

When choosing among power transmission technologies, cooling tower specifiers, contractors and owners must evaluate costs across the entire cooling tower lifecycle. Factors such as energy efficiency, ease of maintenance, reliability and service life must be balanced against initial investment, installation costs, operational complexity and environmental impact.References

A Look at Belt, Chain and Gear Drive Technology, Power Transmission Engineering, https://www.powertransmission.com/blog/a-look-at-belt-chain-and-gear-drive-technology/For more information:

SPX Cooling Technologies, Inc.

Phone: (800) 462-7539

spxcooling.com

About the Author: Jerome Jennings is a global product manager for field-erected components at SPX Cooling Technologies, based in Overland Park, Kansas.