A Look at Belt, Chain and Gear Drive Technology

By Jack Warner

The need for producing more energy increases with our rising need for commercial, industrial, and residential space. In North America (including the U.S., Canada, and Mexico) alone, power transmission market estimates at a whopping $70.4 billion, according to a recent report.

In any industrial facility, turbines and motors are used to produce rotational mechanical motion to perform different kind of tasks. The industrial power transmission market works with basic power transmission open-drive products like belt drives, chain drives, gear drives and each has its own set of advantages and disadvantages. In this post, we will look into the pros and cons of these components of power transmission technology.

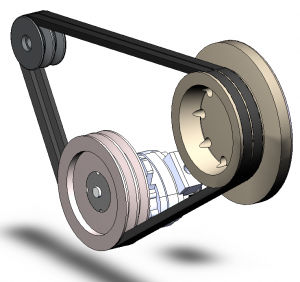

- Belt Technology

One of the most common devices, belt drives are used to transmit motion from one shaft to another with the help of a thin inextensible band that runs over two pulleys. It is basically a looped strip of flexible material that mechanically link the rotating shafts.

There are various kind of belt drives available in the market such as flat belt, V-belt, rope drive, and timing belt. It is important to select the right kind of belt drive, depending upon:

- Power to be transmitted

- Direction of belt motion

- Shaft’s velocity and Velocity ratio

- Service conditions

- Distance between shafts, and space available

Irrespective of the type of belt drive you are using, this technology offers a smooth and effective transmission of power between shafts even if they are at a considerable distance. This technology is used when you need to transmit rotary motion between two parallel shafts. They are the cheapest method of power transmission.

The advantages of a belt drive include:

- Belt drives are cost-effective. New belt drive efficiency can be up to 95-98 percent

- They are simple to use

- Belt drives do not require parallel shaft

- They have a low maintenance cost

- They come with overload and jam protection

- Different speeds can be obtained by means of step or tapered pulleys

- When the distance between shafts is very large, belt drives are the most economical options

- Damp out noise and vibration

- Load fluctuations are shock-absorbed, increasing the machinery life

- Clutch action can be activated by releasing belt tension

However, belt technology also comes with certain disadvantages. These are:

- Belt drives are not compact

- Limited speed of around 35 meters per second

- Compared to other mode power transmission, they have a short life service

- Typically, its operating temperatures are restricted to –35 to 85°C

- Angular velocity of belt drives isn’t constant. This leads to stretching, slipping, and wearing of belt

- It has limited power transmission of up to 370 kW, which increases the heat build-up

- Belt drives usually inflict a heavy load on shafts and bearings

- For wearing and stretching compensation, they additionally need an idler pulley or some adjustment of center distance

- The velocity ratio varies because of belt slip

- Chain Technology

As the name suggests, chain drives come with an endless series of chain links with a net of toothed sprockets. Unlike belt drives, there is no slip in chain technology. However, they are mostly suited for small centre distances, usually up to 3 metre. In some special circumstances, chain drives can even cover a distance of up to 8 meter.

This technology is used for performing three basic functions. These are:

Transmitting power: They can transfer power (speed and torque) from one component to another by means of a linked chain and sprockets. Chain drives can transfer a large amount of torque even within a compact space.

Conveying materials: They can move, carry, slide, push, and pull various materials by attaching buckets, frames, pockets, or meshes to the chains. They are often used for turning rollers to move a conveyor belt.

Timing purposes: Many industries use them to synchronize or time movements.

Just like any other type of mechanical transmission systems, chain drives also have several advantages and disadvantages. The advantages include:

- Positive drives with no slip or creep

- Unlike belt drives, angular velocity remains constant in chain drives

- High-velocity ratio of up to 8:1

- It allows high speed ratio of 8 to 10 in one single step

- Highly efficient, chain drives gives the advantage of more power compared to belts

- It can be used for both small and large center distances

- Chain drives have low maintenance cost

- They give a high transmission efficiency of up to 98 percent

- They can operate even in wet conditions

- More compact and are easy to install compared to belt drive

- Chain drives do not deteriorate due to sunlight, oil, grease, or age

- Lower load on shaft than belt drives

The disadvantages of chain drives

- The initial cost of installation is higher than belt

- The production cost is also relatively higher

- Chain drives need regular lubrication

- Driving and driven shafts must be perfectly aligned and parallel

- They can have velocity fluctuations when unduly stretched

- Not suitable for applications where it is necessary for the drive to slip

- Chain drives are noisy and can also cause vibrations

- They have lower load capacity and service life compared to gear drives

- Gear Technology

In the world of mechanical power transmission, gear drives have a very special and prominent place. This is the most preferred technology when you need to transmit considerable power over a short distance with a constant velocity ratio. The mechanism of gear drives is quite simple – the teeth, which are cut on the blanks of the gear wheel, mesh with each other to transmit power. To avoid slipping, the projections on one disc mesh with the recesses on other disc in gear drives.

This technology uses different types of gears for power transmission. In fact, it can transmit power not only between parallel shafts, but also between non-parallel, co-planar, and intersecting etc. shafts.

The following are the advantages of gear drives:

- They are positive and non-slip drives

- Large and constant velocity ratio of 60:1 can be obtained by using gear trains with minimum space

- Gear drives are mechanically strong, allowing scopes for lifting higher loads

- Longer service life compared to both belt and chain drives

- They can transmit large power

- Gear drives have high transmission efficiency

- They can transmit motion over small centre distance of shafts

- These drives are ideal for low, medium, high power transmission

- Gears can transmit motion even between non-parallel intersecting shafts

- These are the most compact compared to belt and chain drives

Unfortunately, gear drives too have certain disadvantages:

- Gear drives cannot be used for shafts with large center distances

- They are not ideal for large velocities

- These drives require regular lubrication and a more complicated process of applying it

- Noise and vibrations are increased at a high speed

- They are less economical compared to belt and chain drives

- Using multiple gears increase the machine’s overall weight

- They have no flexibility

- Not suitable for transmitting motion over a large distance

- Some part of the machine can get permanently damaged because of the toothed wheel of gears. This is more common in case of excessive loading

Conclusion

Energy is essential for driving the machines and equipment for various applications. Different industries use different power transmission products and sometimes a combination of all to suit their respective needs. So if someone ask which is the best power transmission technology, it will be little difficult to select one over another as these drives come with their own sets of pros and cons. The only determining factor, therefore, should be the task that needs to be accomplished using the power transmission technology. And of course, the budget too.

About the Author: Jack Warner is a tech enthusiast who likes to stay updated with the latest norms in the technology world. He writes for Power Jack Motion, a company which manufactures and supplies motion control components.