Sulzer Brings Motors Back Online and Minimizes Lost Production

Carrying out routine maintenance can be a chore, but failing to complete regular checks on important pieces of machinery can result in unexpected downtime and lost productivity. Sulzer’s service center in Colton, CA, recently completed an urgent repair on a 700 hp (522 kW) motor, caused by a failed bearing, that could have been easily avoided.

A minerals processing company in the USA relies on many large motors to power essential pieces of equipment such as water pumps, pulverizers and vacuum pumps. To minimize the spares inventory, they use similar motors where possible to minimize downtime.

Keeping spares on-hand

For example, seven pieces of equipment are powered by 700 hp medium voltage motors that are now around 20 years old. Aside from the essential spare parts, there is also a complete motor that is used to replace assets that are removed for overhauls every three or four years. However, some of the maintenance routines are a little sporadic.

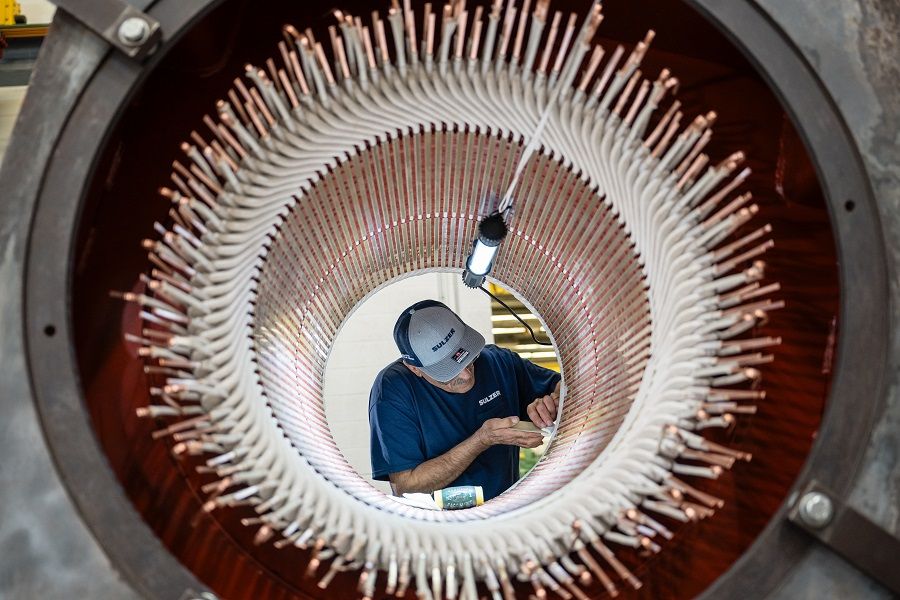

Sulzer has regularly carried out planned maintenance and overhauls of rotating equipment for the minerals company, including the 700 hp motors, which are interchangeable between different applications. When one of the motors failed unexpectedly, it was removed from service and sent to Sulzer’s Colton Service Center for inspection and repair.

When the motor was disassembled, the inspection showed the drive-end bearing had overheated and failed, allowing the rotor to contact the stator, which damaged the windings in both the stator and the rotor as well as the bearing cap. The motor had been overhauled by Sulzer three years previous, so all the technical details of the asset were on record. This made ordering new windings much quicker, expediting the repair process.