Hannover Messe USA - What we Learned

Hannover Messe USA: What We Learned

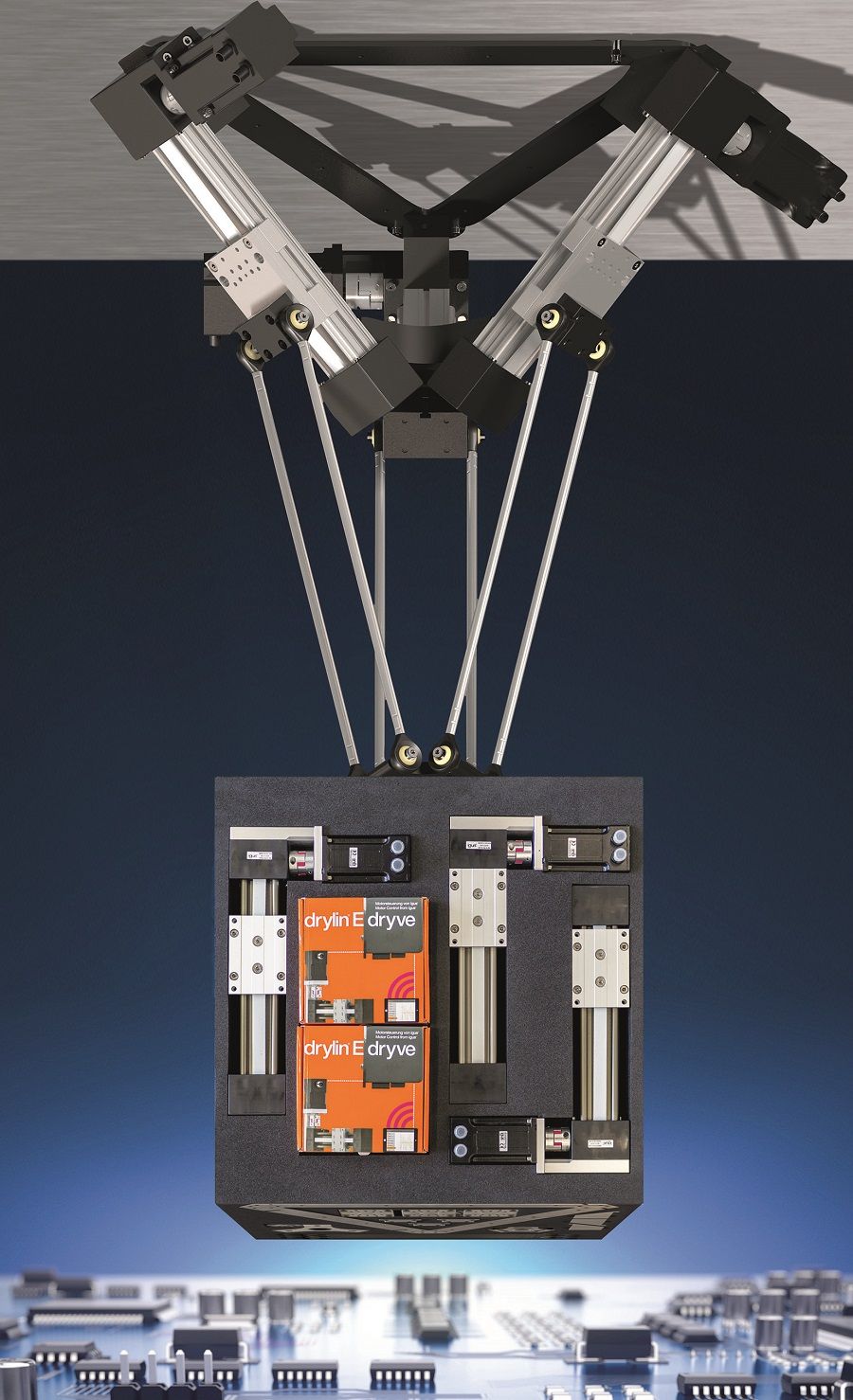

IMTS 2018 had its fair share of machine tools, 3D printers and advanced robotics. Meanwhile, the East Hall — home to Hannover Messe USA — took a more systematic approach, highlighting the smart components and techniques that will be integral in developing the digital factory of the future. Motion control, automation and mechatronics will each play a crucial role particularly as more and more industrial processes become digital. Here are some immediate takeaways from our time spent at Hannover Messe USA:

Industry Innovators are Leading the Way

Companies like Siemens and ABB (B&R Automation) are offering a variety of tools, controls and automation capabilities to improve areas in everything from material handling and packaging to milling gear generation and software.

Case in point: A Siemens booth tour highlighted how shop floor machines will be operated, managed, programmed and maintained in the future. The full process chain — from CAD to CAM to virtual simulation and onto production — gave visitors a sneak peek into life as an engineer in 15 to 20 years.

B&R Automation announced a new communication protocol during the show that will allow all production process data to be transferred using a single protocol. The X20BC008U bus controller functions as an OPC UA server and provides all information about connected I/O modules to OPC UA clients from any manufacturer. This includes, for example, controllers, SCADA systems, ERP systems or cloud applications. It essentially eliminates interfaces, gateways and the associated loss of information that occurred in the past.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.