“We rely heavily on our supplier base for the production of components, allowing us to focus on our core strengths of engineering and system integration. Once our design solution is established, we have a regimented system of part supply and procurement,” Nichols says. “Engineering identifies the part, such as a shaft, collar, roller switch assembly, structural section, motor or bracket, and then procurement places the orders. We emphasize the functionality of the part, the price and the delivery schedule.”

According to Nichols, cost is minimal during the initial design stage. As the design takes shape on the factory floor, however, the cost rises dramatically. Should a part be out of spec, late for delivery, or the quantity not exactly what was ordered, the impact becomes more severe, says Nichols. “In the final stages of assembly and system testing, failures become critical.”

Cincinnati Automation finds success in identifying and establishing relationships with unique suppliers for its component needs, and Misumi USA, Inc. fits right into that description. Headquartered in Schaumburg, IL, Misumi has provided various components for Cincinnati Automation for more than six years.

“Since the first products were sold in 2003, the relationship has developed quite nicely,” says Mike Ricketts, account manager for Misumi. “From an initial six components, Cincinnati Automation & Test now buys over 70 families of products from Misumi. These range from simple washers and linear shafts to locating bushings, circular posts and oil-free bearings.”

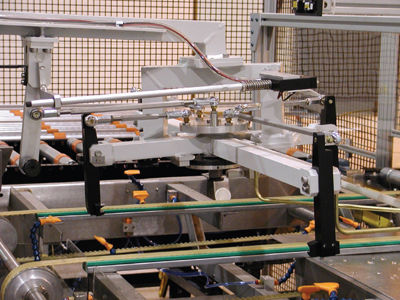

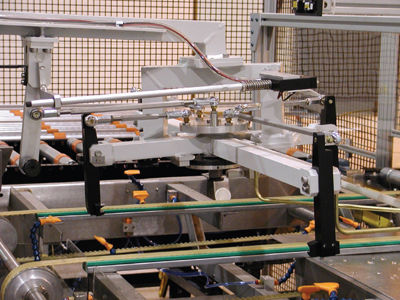

Misumi supplied this gripper mechanism with custom-configured parts for Cincinnati Automation, helping the company enhance their status as a key component supplier.

This relationship works because Misumi boasts a business model that dovetails effectively with Cincinnati Automation. Ricketts calls the configurable component “a toolbox for the imagination” of a machine designer, and customers have repeatedly stated they can receive finished products from Misumi at less cost than bringing the raw materials into their shops for in-house machining.

“We chose Misumi as a supply partner because they have good quality, prompt delivery and excellent cost advantage for us—these factors contribute significantly to our customers’ satisfaction. Often we buy parts in small quantities, and with most suppliers there are cost issues, right from the start. In working closely with Misumi, we quickly realized there were cost and quality advantages to their standard components,” Nichols says.

According to Ricketts, Misumi’s customer base is oftentimes building one-off machines for dedicated operations. In numerous cases, a custom machine is being built with 100 percent Misumi content. Subsequently, when the customer gets reorders or chooses to take the machine to general production, considerable carrying and inventory costs are saved through its unique shipment policy where all the components arrive before the machine enters the assembly phase.

Misumi’s delivery system allowed small and large lots of parts at Cincinnati Automation, whether standard or configured, to arrive on the assembly floor at the optimum time for the machine build schedule. In the overall cost picture described by Nichols, this was a dealmaker, as it complements Cincinnati Automation & Test’s VMI (Vendor Managed Inventory) strategy.

Cincinnati Automation originally sourced a local machine shop for an anti-backup latch for their conveyor systems, but soon realized they could configure and purchase the part directly from Misumi and save time and money.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.