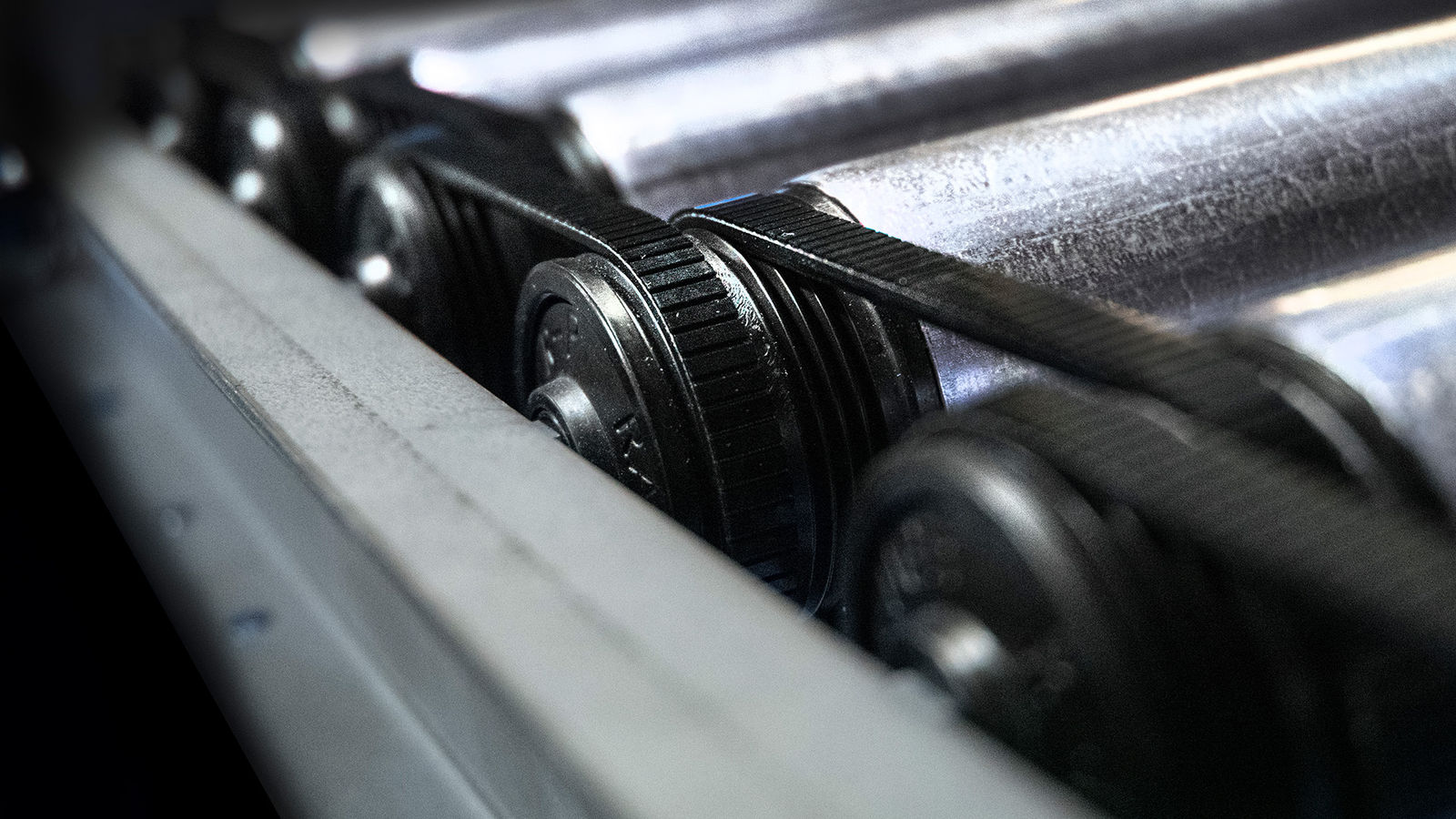

A local sales representative suggested redesigning the roller conveyor system to use Fenner Drives’ Eagle Poly-V belts. Made from polyurethane, Eagle Poly-V belts are available for all kinds of power transmission applications with designs and reinforcement benefits. By eliminating the roller chain, the battery manufacturer reduced noise and eliminated the downtime, labor, and maintenance costs the chain drive required. Forney said Eagle Poly-V products provide a flexible range of solutions depending on the application requirements.

“Reinforcement options or density, rib count, rib profile, material hardness or temperature range, etc. all play a part in the belt design. While this case is focused on material handling with EV batteries, there’s a broader need for customer solutions to solve end user issues including downtime, product performance, and total cost of ownership,” he added.

Forney said one of the many advantages of Fenner’s belt products is the customization capabilities. “We try to provide custom engineered solutions that are precisely tailored to meet the needs of our customer’s applications.”

This follows Fenner Drive’s philosophy of paying attention to the constant flow of feedback and unique application challenges customers face. They’re looking for performance improvements, custom configurations, and material upgrades. Forney reiterated the importance of asking the right questions.

“What equipment are they using and what limitations do they have? For example, what motor capability is there? I attended MODEX this year and we discussed with customers how they look at the application from a total package perspective. We’re trying to solve problems, but we’re not total system designers. You must understand that full application context. What are some of the things we’ve seen in the past that might impact their abilities? Do you have restraints on installation that need to be addressed? We have standard belt sizes, but what if the customer has flexibility on center distances? As we look at our belting portfolio, we’ll determine how to optimize the materials and the technologies our customers need to achieve the best value,” Forney said.

As Fenner works directly with several OEMs, the trick is making sure the engineers are looking at everything involved in the design phase and that they’ve checked all the appropriate boxes before suggesting or customizing the belt for the application.

In a comprehensive comparison by a leading global logistics company, the Eagle Poly-V belt surpassed Rubber Poly-V belts in performance, showcasing superior durability, less frequent replacements, reduced wear and tear, minimal debris, and lower maintenance needs.

For the EV car battery manufacturer, Forney said an advantage was working with a local sales integrator that provided immediate feedback and helped make sure the Eagle Poly-V product was the correct solution over a roller chain drive.

The Eagle Poly-V belt had a significant reduction in decibels, compared to the roller chain. Unlike the roller chain, the Eagle Poly-V belt maintains consistent tension, transmitting the motor’s action immediately to the roller. This provides much more efficient power transmission.