To underscore the viability—and sometimes volatility—of the domestic wind energy market, consider this comment by Ajay Das, general manager/ wind energy for The Timken Company.

“Bearings for wind turbines are

likely to become one of the highest growth segments for Timken into the foreseeable future,” says Das. “The U.S. has huge wind potential.”

And Rotek’s Hersko says that currently bearings for wind turbines constitute “around 40 percent or less” of its business. “It’s huge, and it could be five times that, but we tell manufacturers that we don’t want to promise something that we can’t deliver on.” He adds that ThyssenKrupp is in the midst of investing—after some necessary, farsighted concessions by the state—“hundreds of millions of dollars” in a new Aurora, Ohio-based facility “wholly dedicated to wind energy,” set to open by 2010 or sooner. The net result—over 300 new, good-paying manufacturing jobs for that community. He adds that ThyssenKrupp is building a $3.7 billion steel plant in Alabama. All of this on top of the land office business the company is currently doing in the aforementioned heavy equipment segment, here and abroad.

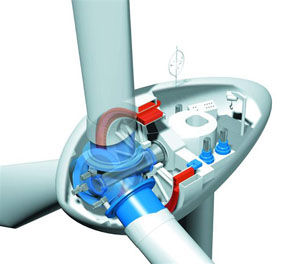

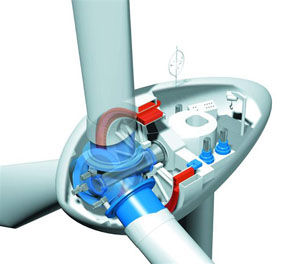

A look at a cutaway illustration of an intricate, Timken-designed bearing set for one of the larger wind turbines.

A birds-eye view of the machine room—including Timken-supplied bearings—of a wind turbine, which dwarfs the landscape. The sheer size of the components needed is a major reason for the ongoing supply chain bottlenecks frustrating industry OEMs and suppliers.

“I’ve been with Rotek some 30 years and I have never, ever, ever seen anything even remotely close to what this market is right now, here and offshore,” he says.

Size and R&D matter. So where does Rotek purchase the precious steel needed for production? “We have agreements with two offshore suppliers and three domestic suppliers,” he says. “Not all of them can supply the necessary sizes or material grades we want. But having said that, what we do is lock in blocks of time for six months (with steel suppliers). But if you’re starting from scratch—good luck. If you’re established (in the industry), it’s about a six- to eight-week wait for steel.”

At Kaydon, the picture is about the same. “We have multiple vendors domestically and overseas to support our demand because we’re dealing primarily with rings from 80 to 125 inches in outer diameter,” says Lage, “and many forging suppliers cannot handle the upper-size range.” Nevertheless, Lage pegs his company’s turbine bearings sales at about 25–30 percent, “And we expect that to continue to grow,” he adds.

And this in an industry that Lage and industry reports see growing as much as 40 percent annually for the foreseeable future. Care to do the math?

Beyond all of these supply-and-demand issues is the actual turbine bearings manufacture; bearings reliant on top-tier engineering and technology in order to ensure their performance, reliability and durability. To meet these challenges, what was done at Timken some years ago is a useful case in point.

Like most wind turbine bearing manufacturers, Rotek is a one-stop shop. That includes gear hardening, as seen here.

“Back in 2000,” says Timken’s Das, “as part of getting into the wind energy business, the first thing Timken did was to create a team of engineers to look at the application—the kind of loads, duty cycles, etc.—and that team of 10 or 12 engineers worked on that for about five years.” One direct result of that R&D was what Timken calls its integrated flex spin bearing. “Those bearings were installed in 2004,” says Das, “and the gearboxes are still running without any trouble.”

At NKE, says Thalmann, there is a clear appreciation of the many complex factors involved in making bearings for such a demanding application.

“Bearings for large turbine gearboxes and mainshafts must fulfill the most stringent quality criteria, as—

especially concerning the required lifespan and operational reliability—these bearings are used in one of the most demanding applications. Exquisite care has to be taken during the specification, design and manufacturing of the bearings and the calculation of the gearbox in order to fulfill the requirements set forth in the applicable standards, and by the customers and the official bodies governing the wind industry.”

Speaking of standards, Lage points out that “Wind turbine builders (here and abroad) follow standards established by Germanischer Lloyd (GL) and certify the entire turbine, so these requirements flow down to the

component suppliers such as bearing manufacturers. Our design engineers take into account the GL requirements along with other design standards.”

An up-close-and-personal view of a nearly completed wind turbine bearing at Rotek. (Photos courtesey of Rotek.)

Standards notwithstanding, what, exactly, is the turbine bearing of choice among designers? It depends, says Thalmann.

“We see different design philosophies in wind turbine gearboxes, without a clear preference for a single bearing type. Several companies (OEMs) prefer tapered roller bearings wherever possible, while others tend to use mainly cylindrical roller bearings. For mainshaft bearings, typically a combination of tapered or spherical roller bearings and a cylindrical roller bearing is used.”

Space does not permit an in-depth look at some of the other exigencies involved in turbine bearing production, such as lubrication and heat treating, for instance, the “black magic” component of any acceptable turbine bearing. Software and other technology advances also play a big part. Look to further issues of PTE and our sister publication, Gear Technology, for more on those issues.

Late to the dance. OK; having cited the numerous supply chain bottlenecks retarding the continued growth of the U.S. wind turbine market—especially bearings—begs the question: Why is this happening? The reasons are many; some understandable, others perhaps having more to do with the current state of manufacturing in the United States.

Lage alludes to the projected 25 to 40 percent annual growth in explaining in part why most U.S. manufacturers capable of entering the turbine market were caught with their collective pants down.

The design and manufacture of the gears, gearboxes and bearings for wind turbines are some of the most intricate and challenging in the industry. These turbines are fitted with Kaydon bearings.

“The growth was unexpected and actually appears constrained by component suppliers,” Lage says. “Ramping up operations for bearings, gears and forgings takes a lot of time versus an assembly operation.”

Says Hersko, “It came so fast. It was so subject to the whim and fancy of Congress with these PTCs (federal incentivizing production tax credits). And the best thing that ever happened to this industry in my mind is that (GE Energy) got into it and they are forcing issues now. I mean, the (U.S.) growth rate that GE is projecting is unbelievable.”

With that said, how long can U.S. wind turbine players expect the shortfall in bearings and other components to last?

“That’s the $25,000 question,” says Lage. “I think maybe a lot of bearing manufacturers are going to remain a little cautious (of ramping up production), because if this wind market repeats previous market declines, there isn’t enough non-wind business to soak up this new capacity.

“The forecasts from industry analysts and our customers are extremely positive, but Congress needs to pass long-term legislation so manufacturers have more stability and can continue their investments in wind.”

For more information:

Brian Lage, business manager

Kaydon Bearings Division

Phone: (231) 755-7038

Fax: (231) 759-4102

www.kaydon.com

NKE Austria GmbH

Ennser Strasse 41a

A4407 Steyr-Gleink, Austria

Phone: + 43 7252 866670-0

Fax: + 43 7252 86667-59

www.nke.at

Rotek, Inc.

1400 Chillicothe Rd.

P.O. Box 312

Aurora, OH 44202

Phone: (330) 562-4000; (800) 221-8043

Fax (Engineering): (330) 562-2709

Fax (Sales): (330) 562-4620

www.rotek-inc.com

The Timken Company

1835 Dueber Ave. SW

Canton, OH 44706

Phone: (330) 438-3000

www.timken.com

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.