Operational Improvements

December 11, 2024

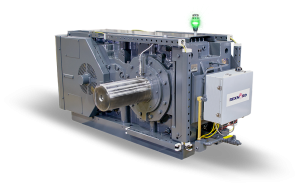

The Smart Gear Drive provides a lot of the standard features you might expect from an IIoT-enabled component. Its primary function is to keep an eye on the most vital performance characteristics of a drive: oil condition, vibration, load, temperature and speed status. The Smart Gear Drive analyzes a drive’s status 24/7, measuring each of these parameters in real time and making sure they always remain within acceptable limits. If the drive’s oil quality becomes poor or it starts suddenly experiencing an unusual amount of vibration while in-operation, Smart Gear Drive automatically alerts technicians of the problem, allowing you to find and solve difficulties and mechanical breakdowns faster and with less risk to the drive.

The Smart Gear Drive provides a lot of the standard features you might expect from an IIoT-enabled component. Its primary function is to keep an eye on the most vital performance characteristics of a drive: oil condition, vibration, load, temperature and speed status. The Smart Gear Drive analyzes a drive’s status 24/7, measuring each of these parameters in real time and making sure they always remain within acceptable limits. If the drive’s oil quality becomes poor or it starts suddenly experiencing an unusual amount of vibration while in-operation, Smart Gear Drive automatically alerts technicians of the problem, allowing you to find and solve difficulties and mechanical breakdowns faster and with less risk to the drive. Designed for the automotive and industrial sectors, Sensotect is a strain-sensitive metal coating that can measure the load conditions on a bearing in places where adhesive bonded strain gauges can’t be utilized. And it does all this with a thickness of under a micrometer, meaning that the design envelope remains unaffected. Sensotect offers accurate, continuous measurement of force and torque without suffering from aging effects or temperature deviations.

Designed for the automotive and industrial sectors, Sensotect is a strain-sensitive metal coating that can measure the load conditions on a bearing in places where adhesive bonded strain gauges can’t be utilized. And it does all this with a thickness of under a micrometer, meaning that the design envelope remains unaffected. Sensotect offers accurate, continuous measurement of force and torque without suffering from aging effects or temperature deviations.