A Look at SKF's Connection to KISSsoft

Recently, the Swedish rolling bearing manufacturer SKF and the Swiss gearbox design software developer KISSsoft have incorporated SKF’s bearing calculation service within KISSsoft's software. With the so-called SKF Bearing Module in KISSsoft, engineers will have direct access to SKF’s bearing technology and bearing performance data. This connection allows for a seamless experience when working on a new gearbox design. Without noticing, an engineer designs a gearbox in KISSsoft ‘as usual’ but is actually connecting to the SKF cloud to retrieve the bearing performance results. These results are based on extremely fast, cloud-based calculation services by SKF in which the operating conditions of the full system are considered when calculating the performance of each individual bearing. As such, a gearbox design is verified more realistically and efficiently as it enables making appropriate bearing choices right from the start.

The user flow is quite simple: First, the user creates a full (gearbox) model in KISSsoft. Then, after registering once for the SKF Bearing Module (using the embedded "SKF Registration Tool"), SKF’s calculation service is called, whenever the bearing performance is calculated to the modified rating life method according to ISO 281. This method can be selected in KISSsoft in the ‘basic data’ window of the bearing and is mandatory if the effects of lubrication and contamination are to be considered.

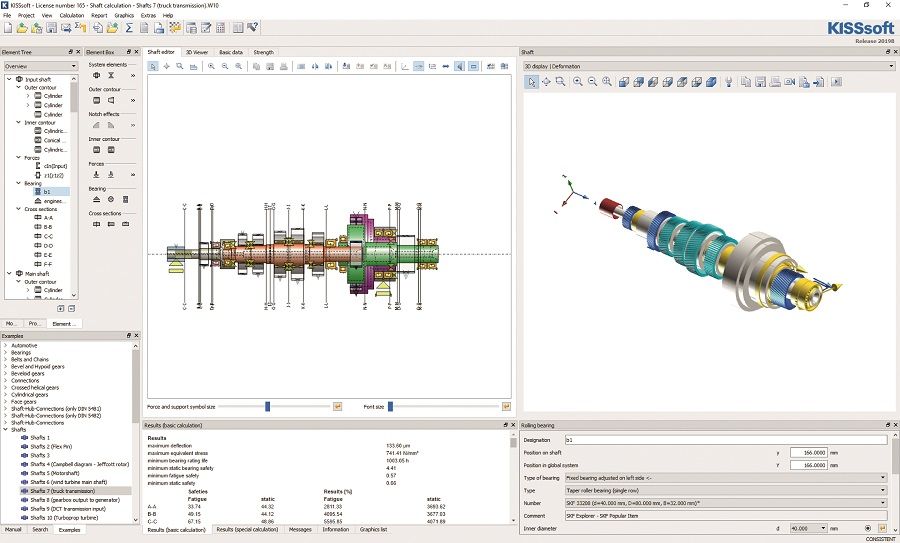

SKF Bearing Module integrated in the shaft calculation of KISSsoft.

SKF Bearing Module integrated in the shaft calculation of KISSsoft.

Modified Rating Life According to ISO 281

If the modified rating life option is not selected, the ISO 281 basic rating life (L10, here referred to as ‘basic ISO 281’) of the bearing is calculated which accounts for the load and speed only. For modern high-quality bearings, the calculated basic rating life can deviate significantly from the actual service life in a given application. Service life in a particular application depends not only on load and bearing size, but also on a variety of influencing factors including lubrication, degree of contamination, proper mounting and other environmental conditions. The ISO 281:2007 modified rating life method (L10m, here referred to as ‘modified ISO 281’) uses a modified life factor (aISO) to supplement the basic rating life. Similarly, for "SKF Rating Life", the life modification factor aSKF applies the same concept of a fatigue load limit Pu as used in modified ISO 281. Just as in modified ISO 281, to reflect three of the important operating conditions, the life modification factor aSKF takes the lubrication conditions, the load level in relation to the bearing fatigue load limit, and a factor ηc for the contamination level into consideration.

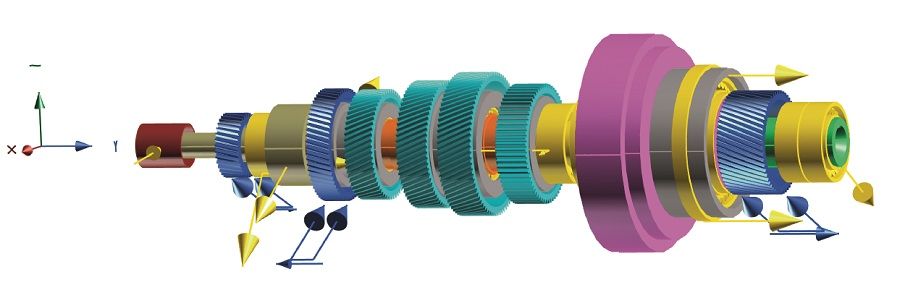

Truck transmission model built in KISSsoft.

Truck transmission model built in KISSsoft.