Wind Pushing Future of Mechanical Components

Wind Pushing Future of Mechanical Components

The global wind power industry is BOOMING again. After a sluggish 2013, annual installations of new wind turbines grew by 44% in 2014, according to the Global Wind Energy Council. And while much of that growth has been in Asia— particularly China, which now leads the world with 114 GW of installed capacity—the USA, Europe, and the rest of the world expect steady growth for the next couple of years as well (Fig. 1).

In the USA, of course, capital investment in wind energy projects is largely influenced by the infamous Production Tax Credit, which the U.S. government allowed to expire at the end of 2014. Despite that, the projects that began prior to the end of last year will keep the industry busy through 2015 and much of 2016.

Windpower 2015

AWEA Windpower Conference &

Exhibition 2015

Orange County Convention Center

Orlando, FL

May 18-21

www.windpowerexpo.org

Learn more about the show on

AWEA’s YouTube Channel at www.

youtube.com/user/americanwindenergy

Featured Exhibitors:

ABB Inc. (Booth 2622)

Aerotorque (Booth 3312)

Bearing Distributors Inc. (Booth 4013)

Beckhoff Automation (Booth 2510)

Bonfiglioli Riduttori S.p.A. (Booth 5222)

Bosch Rexroth Corp. (Booth 4601)

Broadwind Energy (Booth 3810)

Castrol Industrial (Booth 2801)

CENTA Corp. (Booth 3729)

Eickhoff (Booth 2509)

Fuchs Lubricants (Booth 2505)

Kluber Lubrication NA (Booth 4622)

Midpoint Bearing (Booth 3001)

Mobil Industrial Lubricants (Booth 4209)

Moog Components Group (Booth 4204)

Moventas (Booth 2841)

PSL of America (Booth 1929)

Rotek Inc. (Booth 1929)

Rotor Clip Company (Booth 4327)

Schaeffler Group (Booth 2122)

Shell Lubricants (Booth 3627)

Siemens Wind Power (Booth 2522)

SKF USA (Booth 2830)

Svendborg Brakes (Booth 3422)

ThyssenKrupp Rothe Erde GmbH (Booth

1929)

Winergy Drive Systems (Booth 2529)

ZF Services LLC (Booth 2630)

So there’s still reason for optimism, especially if you’re a supplier to the industry. Gear drives, bearings, couplings and related components not only help translate the power of wind into electricity, but they’re also responsible for the many devices on wind turbines that help position the nacelle and blades to maximize productivity.

According to the American Wind Energy Association (AWEA), the U.S. wind-related manufacturing sector consists of more than 550 manufacturing facilities across 44 states, producing more than 8,000 components that comprise a typical wind turbine. U.S.- based facilities make everything from major components such as blades, towers, rotor hubs, generators and gearboxes, to internal components such as bearings, slip rings, brake systems, fasteners, power converters, sensors and control systems—reason enough for readers of Power Transmission Engineering to pay attention.

In fact, the AWEA says that over the past five years, new wind power project installations have grown at an average rate of 36% per year in the USA. This has allowed many U.S. manufacturers to get involved in the industry, bringing down the overall cost of a wind turbine and increasing the amount of U.S. manufactured content from less than 25% in 2005 to more than 67% today.

One of the best places to learn more about how you can get involved in the global wind turbine manufacturing industry is at the AWEA-sponsored Windpower 2015 Conference & Exhibition, which takes place May 18-21 in Orlando, Florida. The annual event features major suppliers to the wind power industry, including many gearbox, bearing and other mechanical component providers (see sidebar for highlighted exhibitors from this year’s show).

For example, the Schaeffler Group (Booth 2122) will present a number of the company’s latest advances for wind turbines, including its FAG X-life cylindrical roller bearings for planetary gears, replace as well as the WiProM portable diagnostic tool, which offers the performance of a permanently mounted system in a rugged, portable unit.

Bonfiglioli’s 700T Series planetary speed reducers are used by a number of leading wind turbine manufacturers for pitch and yaw control. The 700T are flange-mounted reducers with a torque range from 2,500 up to 300,000 N-m. They can be manufactured with three to five planetary reduction stages, providing ratios from 60 to 3,000 (Fig. 3).

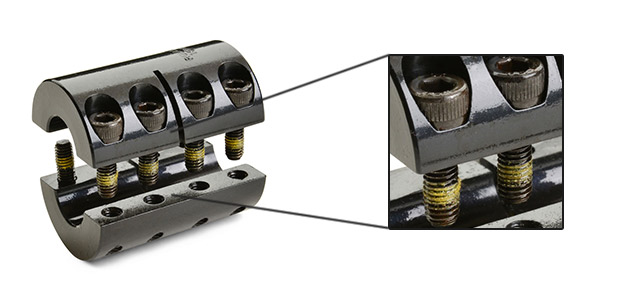

Centa’s Centalink couplings offer misalignment capability up to 2 degrees under rated operating conditions (and up to 6 degrees in exceptional cases). They are available for wind power applications from 6 to 50 kNm, and they’re rated for temperatures from −45°C to 80°C.

In addition to the exposition, Windpower 2015 also offers educational opportunities in the accompanying conference.