This progress can also be assessed

by looking at the power density of the

gearbox that is particularly relevant

in the matter of automotive transmissions.

An analysis of automotive gearboxes

(Ref. 7) shows that this parameter

approximately doubled during the last

30 years. During the same time period

the reliability of rolling bearings for

gearboxes also increased by a factor of

three (Ref. 7), allowing for a 70% improvement

of the torque density of automotive

transmissions (Ref. 37; Fig. 2).

Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37).Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37).

This real progress would not have

taken place had gearbox designers

not benefitted from the simultaneous,

continuous progress in rolling bearing

technology that characterized the same

time period. Indeed, due to the stress

concentration of the rolling contact and

the number of rolling elements, rolling

bearings are in general the heavieststressed

and the highest-fatigue-cycled

component of a mechanical system.

The fact that the life expectancy of

an entire system depends on its weakest

link makes the reliability of a few

critical bearing components vital for

the reliability of the whole transmission,

and it pushes for the development

of bearings with an extended life. The

progress achieved in increased rolling

bearing reliability can be visualized in

the development of the ISO 281 rated

life, relative to the original ISO 281:1962

level (Fig. 3).

Figure 3 Typical progression of the ISO rated life of a radial ball bearing, loaded at C/P = 8;

contamination factor = 0.5; viscosity ratio of lubrication = 1 and 4.

Figure 3 shows normalized rated

lives to the initial ISO 281:1962 rating.

As discussed in the introduction, the

ISO 281:1962 was the direct result of

a draft proposed by the Swedish delegate

Palmgren to the ISO Technical

Committee in 1952. This draft basically contained the bearing rating rules developed

by SKF during the previous two

decades of research.

In the following period, thanks to the

newly discovered elastohydrodynamic

lubrication (EHL) mechanism, the effect

of the lubrication quality on the expected

bearing life could be addressed

and an intensive research program was

initiated at SKF. This research work was

carried out with the prominent contribution

of T.E. Tallian in Philadelphia

(Refs. 9-11) and by S. Andréason in Gothenburg

(Refs. 12-14). The results of

this work were also made available via

SKF catalogs (Refs. 15-16) and to the

ISO Technical Committee for further

standardization (Ref. 17). This led to

ISO 281:1977 (Ref. 17). In this new version

of the ISO standard, adjustment

factors for the lubrication condition of

the bearing, i.e., the viscosity ratio (The

viscosity ratio, κ, is defined as the ratio

of the actual viscosity, v, to the rated

viscosity, ν1, for adequate lubrication,

when the lubricant is at normal operating

temperature. To separate the bearing

contact surfaces, a minimum viscosity

ratio κ = 1 is required. Full-film conditions

exist when κ ≥ 4, i.e., a sufficient hydrodynamic

film is formed for adequate

lubrication. K = v/v1 Ref. 16), and material

quality were introduced into the

life rating equation. Although extensive

guidelines were given, the adjustment

factors were not directly provided in the

standard but they needed to be specified

by the bearing manufacturer.

In the 1970s material manufacturing

technology related to cleanliness made

substantial progress, thanks to vacuum

degassing and other techniques,

to prevent or reduce the formation of

micro-inclusion and defects in the steel

matrix. Research to quantify the effect

of material-increased cleanliness on

bearing fatigue life was conducted, primarily

at the two main laboratories in

Gothenburg and Philadelphia, and also

in the new corporate SKF Engineering

& Research Center (ERC) located in the

Netherlands.

This intensive effort provided hundreds

of test results and a very robust

experimental base to justify an upgrade

of the dynamic load ratings of rolling

bearings. This upgrade was introduced

in the SKF catalogue of 1981 (Ref. 18)

and integrated into the ISO dynamic

load rating standard about 9 years later,

with ISO 281:1990 (Ref. 19).

Introduction of Modified

Bearing Rating Life

In the 1980s, SKF research (Ref. 20)

found that the performance of rolling

bearings could no longer be accommodated

with just a linear adjustment of

the basic load ratings, as was done until

then. Substantial modifications were

required; i.e., a significant non-linear

modification of the basic load rating of

the bearing was developed (Refs. 20-21).

It was found that the new calculation

method could introduce, under certain

conditions, a change to the rated life for

a factor up to 50 times (Eq. 2). Despite

the groundbreaking modifications to

the old calculation routines, the new

methodology was introduced in the

SKF catalogue 4000 in 1989 (Ref. 22)

with the addition of a stress life modification

factor, aslf, that combines the effect

of the bearing fatigue load limit and

the additional stress system related to

the contamination level and lubricant

quality of the contact.

Where

-

L10 mod is modified rating life (at 90%

reliability), million revolutions

-

aslf is life modification factor.

In 2003 the calculation method was

in use already for many years with good

results, thus on initiative of the German

standardization organization DIN, the

SKF life rating method was adopted as

DIN 281 Addendum 1:2003. Further

discussions for the standardization of

the new methodology were also initiated

by the ISO Technical Committee.

To support this process, disclosure

of the SKF theory and related experimental

bases of the new method was

also undertaken (Ref. 23). More than

260 test series (approx. 8,000 bearings)

were tested to support the development

and validation of the new method.

This and other results were published

(Refs. 23-24) to further sustain

ISO standardization of the modified life

rating calculation model. This process

was concluded in 2007 and is the basis

of the present ISO 281 rating standard

(Refs. 25-26).

From the analysis of the evolution of

ISO 281 it is evident that rolling bearing

technology has made gigantic strides

during the last 50 years, and this progress

is an important aspect of the substantial

improvement in the total efficiency

and reliability of mechanical

systems such as gearboxes and transmissions.

This progress, however, does

require the availability of a significant amount of endurance test data for the

statistical validation of the improved

rating rules in the dynamic loading of

bearings.

Given the high costs involved for the

endurance testing of large numbers of

bearings, only some large bearing manufacturers

are able to financially support

the investment to finance and conduct

such large test campaigns. In time,

this also leads to dynamic load rating

standards that reflect the performance

and quality of the bearing products of

the main bearing manufacturers, rather

than the average or lower-quality present

in the market.

This implies some uncertainties for

the bearing user and gearbox designer,

as the ISO ratings are universally employed.

In principle, the same dynamic

load rating is obtained from bearings

with the same internal geometry, but

quite different surface microgeometry;

waviness; raceway; rolling element profilometry;

shape; internal precision and

tolerances; material fatigue strength;

and type of heat treatment. Indeed,

there are many other detailed aspects

of the bearing design, such as cage and

seals, which are not included in the ISO

281 rating system but are known to affect

the performance of the bearing in a

very significant way.

To cope with this situation, main

bearing manufacturers have developed

in-house, advanced computer software

for the detailed modeling and simulations

of rolling bearings, surrounding

parts, and complete mechanical

system. Advanced simulation tools

include the static, quasi-static and dynamic

analysis of the shaft-bearing

housing system. The bearing internal

geometry, mounting interface as well

as shaft and housing behavior are taken

into account when analyzing a bearing

solution (Refs. 28-29). These computer

tools are maintained and updated with

the most recent results of bearing performance

from new product development

and endurance testing.

On the other end of the spectrum, it

is also found that other bearing companies

that lack specific knowledge

and testing facilities can simply exploit

the ISO 281 simplicity of rating rules to

their own advantage. Dynamic ratings

of bearings based on the simple application

of ISO 281 without testing and

validation procedures of the product

may lead to bearing dynamic load ratings

that appear equal or even superior

to its competitive offerings on the surface,

only to fall short to a close examination

or when they are in use in the

actual application.

Different Practices behind

Catalogue Values

As just described, it is important to verify

that catalogue values are backed up

with sufficient test data and that are in

line with ISO 281, by reading carefully a

supplier's catalogue and technical material.

This section will provide examples

of misleading practices sometimes

in use.

To provide an overview of the different

dynamic load rating practices

presently in use, roller bearings of different

manufacturers were investigated

and their ISO 281 dynamic load ratings

were calculated and compared to the

their catalogue values. The result of this

survey is given in Figure 4 for five samplings.

This will be discussed in terms

of generic rating strategies found in

today's marketplace that are in current

use.

Figure 4 Overview of different dynamic rating rules found in the market place; to simplify the discussion, of the competing product to the benefit

the life modification factor — aISO — is taken for all cases equal to 2.5.

For Case (A), Figure 4, bearing products

of standard (std.) quality are rated

according to ISO 281; the basic rating

life therefore remained unchanged. For

a given assumed load, lubrication and

speed conditions, it is possible to have

a typical ISO 281 modification factor

equal to 2.5. Thus the application of

such modification factor provides an

increase of the rated life of 2.5 times as

expected. Case (A) has also introduced

a new bearing class different from the

standard for extended (ext.) performance.

After exhaustive testing, Case

(A) found that the load rating of the

new product needed to be adjusted to

accommodate for the increased performance

of the product. The fatigue performance

of the new (ext.) product indicated

a 15% increase of the dynamic

load rating with the required high level

of experimental confidence.

This moderate change of the dynamic

load rating is then amplified by the loadlife

exponent, leading to a 60% increase

of the basic rated life (Fig. 4). This life

increase will be further magnified by

the application of the life modification

factor (i.e., 2.5), leading to a modified

life that is four times the original ISO

basic rated life of a standard product.

Case (B), following the increased rating

introduced by case (A), after some

product and process development, is

able to match the new performance

class and, with the help of validation

tests, it releases a product that is also

rated with a 15% increase of the dynamic

load rating. In this way, Case (B)

is able to match the technical challenge of the competing product to the benefit of widening consumer choice and market

competition.

However, there is also Case (C),

which has the goal to present the most

favorable impression possible of the

strength of its products, thus publishing

a 24% increase above the ISO 281 ratings

for some of its products — without

known statistical test back-up data.

This 24% increase happens to correspond

exactly to the doubling of the

basic rated life of the bearing, which is

quite fortunate as this can facilitate the

communication with costumers and

the marketing of the bearings. Note

that this increase of the basic rated life

is further amplified by the use of the

modification factor leading to a modified

rated life that is five times the original

ISO basic rating.

The investigation of bearings from

Case (D) revealed a rather interesting

rating strategy. Similar to Case (C), this

case does not seem to have any catalogue

data back-up with test results.

Nevertheless, Case (D) introduces a

36% increase of the dynamic load rating

in his bearing catalogue.

The basic life rating associated to

such an increase is 2.8 times the ISO

basic rated life. Thus it seems that this

case of manufacturers has simply transformed

a life modification factor equal

to 2.8 into a dynamic load rating of the

bearing. A further investigation about

the way the life is calculated by Case (D)

confirms this. Indeed, contrary to ISO

281, it appears that Case (D) advises

customers to apply a life modification

factor that must be, at the best, lower

than one. This clearly indicates that

Case (D) applies a strategy to obtain

load ratings that are artificially inflated

just to create the perception of benefit

into the buyer, and not at all in line with

ISO 281 definition.

This practice might create several

problems to a not-well-informed designer.

Indeed, such designer, working

on the assumption that the dynamic

load rating declared by this manufacturer

is ISO 281-compatible, will most

likely introduce the declared catalogue

rating in calculation routines that make

use of the ISO 281 modification factor,

falsely leading to a predicted life that

can be up to seven times the original

ISO 281 basic life (for a 2.5 modification

factor, as used for the other cases).

This significant effect on the calculated

life is shown with the light gray column

of Case (D) (Fig. 4), to indicate that

this rated life is not compatible with the

ISO 281 modification factor. Clearly,

this is a misleading way of rating bearing

performance, which may lead to

products that, in real applications, may

not be able to reach their reliability target

and fail their design expectations.

The examples depicted in Figure 4

show that engineers should be skeptical

of bearing manufacturers catalogue rating

information, and that they should

understand what is being offered in detail

— even if the information is labeled

as ISO 281.

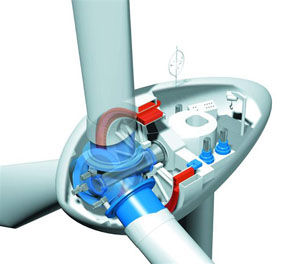

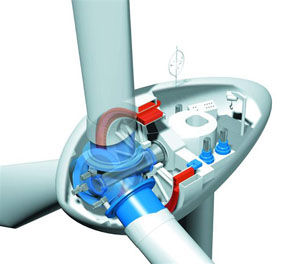

Figure 5 Schematic of a three stages helical gear unit and bearing arrangements.

A Safe Criterion for the

Selection of Rolling Bearings

At the present time, making a decision

based only on the dynamic load rating,

(the C value) of the bearing taken

from manufacturers catalogues can be

a treacherous affair.

Reliance only on the declared catalogue

figure of C can in some cases lead

to the wrong choices. Some suppliers

will always look for ways to prove the

benefits of their products to the customers,

and inflating the dynamic load

rating C is a simple and effective way

to do this. To make the most informed

decision possible, users must pay attention

to the details, ask hard questions of

their suppliers, and always read the fine

print.

Once the C value is understood and

verified, the next step to do a proper design

selection is to also look at the modified

life rating of the particular bearing

application, rather than only the published

value of C. As it will be discussed

in the following gearbox calculation example,

and, as general rule, it is indeed

the modified rated life of the bearing,

L10m, rather than the dynamic load rating

C, that provides the most valuable

information regarding the performance

of a bearing product with regard to the

particular application.

The modified rated life combines

the basic rating life with the stress-life

modification factor. The comparison

of L10m will avoid hidden aspects in the

particular definition of either factor.

As will be shown hereafter, by using a

bearing selection criterion based on the

modified rated life L10m, users can avoid

pitfalls and arrive at informed decisions

for the selection of their bearings and

the optimization of their products.

Example of Newest Method for

Gearbox Bearing Design

The following bearing application example

was selected to illustrate that the

dynamic load rating of the bearing C is

less crucial as generally believed, than

is the actual expected performance of a

bearing application. The purpose of this

example is to highlight that using modern

life calculation methods provides

more understanding to the designer

of what issues may be faced by bearings,

and consequently more chance to

the designer to make adequate design

choices. Comparisons of different life

methods have been done by Uherek

(Ref. 36) for several gearboxes. In these

analyses, it is observed that contamination

and lubrication were already key

factors in the design.

The application example is a threestage

helical gear unit, with the following

general characteristic and design:

- This gear unit has a reduction ratio of

40, with 3 stages

- The input speed is 1,400 rpm

- The nominal power is 66 kW, which

correspond to an output torque of 18

kNm

- Lubricated with circulating oil with

filters, mineral oil of 320 mm2/s @

40°C

- The contamination level (for the

contamination factor ηc) is ranked

ISO -/17/14

- It is assumed that the operating

temperature is 80°C

- Examining the results of Table 1 and

Figure 6, the following observations

can be made:

- There is no direct correlation

between the dynamic load rating,

i.e., basic rated life, and the

actual modified rating life of the

application.

- The basic rating life doesn't show the

bearings that are at risk, i.e., shorter

lives. Indeed the bearings that are

most at risk are: the Intermediate

shaft 2B and the output shaft B, both

bearings were indicated as quite safe

by the basic rated life.

- The modified rating life clearly

indicates that two bearings that

have shorter lives, and also the

technical reasons behind the

reduced endurance, i.e., lubrication

(low κ) and contamination issues

(low contamination factor ηc). Thus

surface fatigue problem can be

expected rather than subsurface

fatigue.

A usual procedure that is utilized

when life values are found too short is to

select a bigger bearing, due to its higher

capacity. However, the designer must

be aware that the selection of bearings

with an increase of the dynamic load

rating C would not solve the lubrication

and contamination issue. Even if an increased

capacity would show a slightly

longer life (a 10% higher capacity

leads to 33-37% higher life), it does not

change the phenomena: the problem

is surface induced stresses, originated

by the surface micro-geometry and the

effect of solid particles. Also in today's

gearbox, due to their high power density,

the space is often limited, and it

can be impossible to consider a bigger

bearing size, as a solution.

These stresses can't be reduced by an

increase of the dynamic load rating of

the bearing. Corrective actions to improve

the reliability of the intermediate

(2B) and output shaft (B) bearings

require not an increased dynamic load

rating of the bearing but actions to improve

the tribology of the surfaces in

contact, (Refs. 30-31). Therefore, proven

EP additives in the lubricant and

preventive measurements to reduce the

presence of particles and debris in the

oil can provide good results.

According to the analysis of the modified

life rating calculation, it is possible

to propose the following improvements

to increase the life of the weakest two

bearings:

- Use oil containing effective EP

additives

- Improve the cleanliness to ISO

-/15/12 level

- Both corrective actions at the same

time

Figure 7 shows the relative improvements

that would be possible to achieve

in relation to the original modified life

rating shown in Figure 6.

Figure 6 Overview of the modified life rating of the gearbox bearings normalized to the basic rating.

- Examining the results of Figure 7, the

following can be found:

- The use of oil containing proven EP

additives would provide the most

significant improvement—especially

in the two low-speed output shaft

bearings.

For the intermediate shaft bearing

(2B), an improvement of 40% is obtained

by improvement in the oil cleanliness.

Combining this improvement

with an optimized EP-additive of the oil

can provide a further 80% life increase,

thus enabling attainment of the required

rated life for this class of applications.

This gearbox bearing calculation example

shows how to use the modified

rated life of bearings to improve the

performance of a few critical bearings.

Yet doing so will provide significant increased

performance to the complete

system. This transparent and simple

optimization process would not be possible

using the basic rating life or selecting

the bearing based only on the value

of the dynamic load rating C.

Indeed, for the input shafts A and B

the dynamic load rating is quite unimportant

as the size of the bearing is dictated

by the required shaft size. On the

other hand, for the intermediate and

output shafts, the use of the basic load

rating C would give no useful information

for the improvement of the long

term reliability of this gearbox. Selection

of the input shafts A and B bearings

based on inflated values of the dynamic

load ratings C to reach an increased reliability

for the system would fail. This

is because it would not address the

elimination of the surface stress system

related to the low speed of the output

shaft with a viscosity ratio (κ) of 0.3.

Of course the final design decision

must take other parameters and constraints

into account, but applying the

modified life rating method allows the

designer to make more informed decisions

on alternative solutions with an

enhanced understanding of bearing

operating conditions and the expected

consequences of the application performance.

Figure 7 Relative increase of bearing life as result of corrective actions about lubricant EP additives and improved cleanliness of the oil.

Further Discussion on

Selection Criteria of Rolling

Bearings

The above gearbox bearing calculation

example shows that the design optimization

process can only be applied if the

life calculation informs the designer on

potential problems and hidden risks.

This should be done by looking at the

modified life rating, as the basic rated

life would be not able to provide such

critical information.

The basic rated life and the dynamic

load rating C basically represent the

subsurface fatigue performance of the

bearing. In other words, the fatigue performance

at extremely high load C/P~2,

and as such it cannot contribute much

to applications normally operating at

much lower loads for reliable operation

and extended periods of time.

Gearbox designers that rely solely on

the C/P parameter as a selection criterion

for the bearing can also easily

fall into believing that higher C values

will ensure a higher reliability for the

application. In such a case the attraction

for the selection of bearings with

inflated dynamic load ratings C will be

irresistible, with possibly unfortunate

consequences for the actual field performance

of the application.

To explain this important issue in

some detail we refer to the contact pressure

and related subsurface von Misses

stress field in the case of two rolling

bearing contacts — one (a) with an idealized

nominal smooth geometry, the

other (b) with its real surface micro-geometry

in contact (Ref. 27) (Fig. 8).

Figure 8 Example of stress field a) nominal smooth contact geometry, b) actual rough geometry

(Ref. 27).

In the case of reduced lubrication or

a presence of contamination particles,

the contact (b) will exhibit a severe

stress system right at the surface of the

rolling contact. This stress system is the

direct result of the asperities and microprofile

geometry that are not part of the

ISO specification of dynamic load rating

C (which refers to the nominal geometry

of the bearing and good lubrication

conditions, i.e., good separation

of surfaces by a clean lubricant film).

Therefore these stresses can't be reduced

by adopting a bearing with increased

C. Note that if a bearing rated

with an inflated C, and used under the

same C/P conditions, will lead to the

actual increase of the contact pressure

and a further intensification of the surface

stresses of the contact.

The problem of reducing high surface

stress in the rolling bearing is therefore

not by acting on the dynamic load rating,

but by acting on the tribology of the

Figure 7 Relative increase of bearing life as result of corrective actions about lubricant EP additives contact for the restoration of the protecandtive lubricant film or reduction of geometrical

imperfections. As discussed

earlier in this paper, this means working

with the chemistry of the lubricant

and preserving the geometrical quality

of the rolling surfaces by improvement

of the lubricant cleanliness.

Failure Mode from the Field

and Implications for Bearing

Selection

There are several studies about the type

of damage found in bearings that are

replaced during routine maintenance

work. Engel and Winter (Ref. 32) in 1979

reviewed the results of damaged bearings

originated from an estimated total

installed bearing population of several

million bearings and arrived at the

conclusion that although actual failed

bearings are very small in proportion

of the original population (0.05%), the

predominant failure mode in the field

is either lubrication- or contaminationrelated.

They found that lubrication and oil

contamination account for 75% of all

bearings failure. This same conclusion

is also reported by Nierlich and Volkmuth

(Ref. 35), who reviewed detailed

previous data, correlating this to detailed

observations and measurements

of damaged bearing surfaces.

In a separate and extensive investigation

supported by the German research

council for drivelines technology

(Ref. 33), conducted among the member

companies of the FVA association,

it was found that the most predominant

bearing failure modes experienced in

the field were inadequate lubrication

and contamination. This investigation

also reported and discussed in detail

with other results by Gläntz (Ref. 34).

From the observation of the failure

modes of field bearings, one can conclude

that subsurface fatigue-initiated

failure is in fact very rare. This is to be

expected, as most bearing applications

are selected based on a C/P design criterion,

which is a good method to avoid

classical subsurface-initiated fatigue

failure—particularly under good lubrication

conditions (Fig. 9).

Figure 9 Causes of rolling bearing failure as percentage of responses from an enquiry among the

companies of the FVA associations (Ref. 34).

However, the presence in the marketplace

of artificially inflated dynamic

load rating C may put in jeopardy this

good record. Indeed, as observed earlier,

today there is the risk that the unusually

increased C figures may correspond

in reality to a lower expected

dynamic carrying capacity of the bearing,

leading to a reduction, rather than

an increase, of the actual reliability of

the application.

Conclusion

Today's gearboxes require high reliability

and extended life. The trend to increased

performance will continue in an

effort to develop more energy-efficient

mechanical systems. At present the most

commonly used method of selecting a

bearing for a given application is based

on the dynamic load rating C. This paper

has shown very clearly that this methodology

has several drawbacks and may

not lead to an increased reliability for the

system. To avoid risk of reduced or unexpected

performance, well-informed

designers should base their decision on

these simple and practical rules:

- Engineers should look with critical

eyes the printed C values in bearing

catalogues, looking for consistency

with either ISO 281 or bearing

manufacturer testing practices.

- Today, the use of the modified

rated life is straightforward and

transparent. It is fully documented

in the ISO 281 and based on physical

operating characteristics of the

bearing, as viscosity ratio of the oil,

pitch diameter, lubricant cleanliness

class, rotary speed of the bearing etc.

The use of this calculation should

replace current simple practices

based only on the use of the C value.

- As shown in the gearbox calculation

example:

- Bearing lives based on the

modified rated life can provide

expected lives that can be larger than the basic rating life. These

are the bearings that are normally

scrapped as not failed at the end of

the gearbox life.

- There are also some bearings that

are critical for the reliability of

the system. The modified rating

life "ISO 281" is the only public

tool available to detect bearing

criticality and evaluate possible

corrective design modifications for

performance optimization.

Acknowledgment. The authors wish

to thank Mr. Alexander de Vries, Director

SKF Product Development, for his

permission to publish this article.

Antonio Gabelli is senior

scientist working at SKF

on tribology and rolling

contact fatigue life of rolling

bearings. He joined the

Engineering and Research

Center of SKF in Netherlands

in 1981, since than he

published many research papers on fatigue

and lubrication of rolling bearings. He was one

of the key contributors to the new bearing life

theory, developed by SKF in the 90's He is also

author of several patents on rolling bearings.

He holds a mechanical engineering degree

from the University of Padua (Italy) and a PhD

degree in from Chalmers Technical University of

Gothenburg (Sweden).

Antonio Gabelli is senior

scientist working at SKF

on tribology and rolling

contact fatigue life of rolling

bearings. He joined the

Engineering and Research

Center of SKF in Netherlands

in 1981, since than he

published many research papers on fatigue

and lubrication of rolling bearings. He was one

of the key contributors to the new bearing life

theory, developed by SKF in the 90's He is also

author of several patents on rolling bearings.

He holds a mechanical engineering degree

from the University of Padua (Italy) and a PhD

degree in from Chalmers Technical University of

Gothenburg (Sweden).

Upon graduation in 1999

with a degree in mechanical

engineering from Technical

University of Compiegne

(UTC), France, Armel Doyer

joined SKF the following

year in the company's

development department for

deep-groove ball bearings.

He has since held various positions within

that department, focusing predominantly on

automotive and industrial applications, where

he contributed to SKF's first launch of energyefficient

bearings. Doyer since 2008 has been

working as a project engineer within SKF's

Industrial Drive organization, with a focus on

understanding industry technical needs and

in support of SKF's development towards the

industrial gear unit market.

Upon graduation in 1999

with a degree in mechanical

engineering from Technical

University of Compiegne

(UTC), France, Armel Doyer

joined SKF the following

year in the company's

development department for

deep-groove ball bearings.

He has since held various positions within

that department, focusing predominantly on

automotive and industrial applications, where

he contributed to SKF's first launch of energyefficient

bearings. Doyer since 2008 has been

working as a project engineer within SKF's

Industrial Drive organization, with a focus on

understanding industry technical needs and

in support of SKF's development towards the

industrial gear unit market.

Guillermo E. Morales-

Espejel is principal scientist,

SKF Engineering & Research

Centre, The Netherlands,

and a visiting professor at

LaMCoS, INSA de Lyon. He

holds a PhD in tribology from

the University of Cambridge,

a "Habilitation à Diriger des

Recherches (INSA-Lyon),” and has15 years of

experience in rolling bearings. Morales-Espejel

has authored more than 50 scientific papers and

several book chapters with a focus on bearing life,

friction, lubrication and surface life.

Guillermo E. Morales-

Espejel is principal scientist,

SKF Engineering & Research

Centre, The Netherlands,

and a visiting professor at

LaMCoS, INSA de Lyon. He

holds a PhD in tribology from

the University of Cambridge,

a "Habilitation à Diriger des

Recherches (INSA-Lyon),” and has15 years of

experience in rolling bearings. Morales-Espejel

has authored more than 50 scientific papers and

several book chapters with a focus on bearing life,

friction, lubrication and surface life.

References

- Palmgren, A. "On the Carrying Capacity and

Life of Ball Bearings," Ball Bearing Journal,

034, pp. 34-44, 1937.

- Lundberg, G., and A. Palmgren. "Dynamic

Capacity of Rolling Bearings," Acta

Polytechnica Mechanical Engineering Series,

Royal Swedish Academy of Engineering

Sciences, Vol. 1, No. 3, 7, (1947), and Vol. 2,

No. 4 (1952).

- Weibull, W. A Statistical Theory of the

Strength of Materials, Ingeniors Etanskaps

Akademien Handlingar, 1939, 151, p. 45.

- Lieblein, J. and M. Zelen. "Statistical

Investigation of the Fatigue Life of Deep-

Groove Ball Bearings," Journal of Research of

the National Bureau of Standard, Vol. 57, No.

5, Research Paper 2719, November, 1956, pp.

273-316.

- Tallian, T.E. "Weibull Distribution of

Rolling Contact Fatigue Life and Deviations

Therefrom," ASLE Transactions, Vol. 5, No. 1,

April 1962.

- Wallin, E. "Rolling Bearing Reliability:

Service Experience and Product

Development," Ball Bearing Journal, 221,

1984.

- Fleck, W. "Design Prospective Power-Density

Concept for Gearbox Bearings," Automotive

Engineer, August, 1992, pp.50-54, AGMA

14FTM16

- ISO 281:2007. Rolling Bearings — Dynamic

Load Ratings and Rating Life, 2nd Ed., 2007.

- Tallian, T.E., Y.P. Chiu, D.F. Huttenlocher, J.A.

Kamenshine, L.B. Sibley and N.E. Sindlinger.

"Lubricant Films in Rolling Contact of Rough

Surfaces," ASLE Trans., 1964, 7, 109–126.

- Tallian, T.E., L.B. Sibley and R.R. Valori.

"Elastohydrodynamic Film Effects on the

Load-Life Behavior of Rolling Contacts," In

Proceedings of the ASME Spring Lubrication

Symposium, New York, 8 June, 1965, ASME

paper no. 65-LUBS-11.

- Liu, J.Y., T.E. Tallian and J.I. McCool.

"Dependence of Bearing Fatigue Life on Film

Thickness To Surface Roughness Ratio," ASLE

Trans., 1975, 18, 144–152.

- Andréason, S. "Life and Reliability of Rolling

Bearings," Ball Bearing Journal, 168:1971.

- Andréason, S. and T. Lund. "Ball Bearing

Endurance Testing Considering EHD Lubrication," In Proceedings of the Leeds

EHL Symposium, 1972, Vol. C36, pp. 138–141

(Professional Engineering Publishing, St

Edmunds, London).

- Andréason S. and B. Snare. "Adjusted Rating

Life of Rolling Bearings," Ball Bearing Journal

184, 1975, pp. 1-6.

- SKF Publication 2800. General Catalogue,

SKF Gothenburg, Sweden, 1970.

- SKF Publication 3000. General Catalogue,

SKF Gothenburg, Sweden, 1978.

- ISO 281/1:1977 (E). Rolling Bearings

Dynamic Load Rating and Rating Life.

- SKF Publication 3200. General Catalogue,

SKF Gothenburg, Sweden, 1981.

- ISO 281/1:1990 (E). Rolling Bearings

Dynamic Load Rating and Rating Life.

- Ioannides, E. and T.A. Harris. "A New Fatigue

Life Model for Rolling Bearings," Trans.

ASME, J. of Trib., 107, pp. 367-378 (1985).

- loannides, E., B. Jacobson and J.H. Tripp.

"Prediction of Rolling Bearing Life under

Practical Operating Conditions," Proc. 15th

Leeds-Lyon Symp. on Trib., Leeds 1988,

Elsevier, pp.181-187, 1989.

- SKF Publication 4000. General Catalogue,

SKF Gothenburg, Sweden, 1989.

- Ioannides, E., G. Bergling and A. Gabelli. "An

Analytical Formulation for the Life of Rolling

Bearings," Acta Polytechnica Scandinavica,

Mechanical Engineering Series No. 137,

pp 9-12, 21-24, The Finnish Academy of

Technology, 1999.

- Gabelli A., G.E. Morales-Espejel and E.

Ioannides. "Particle Damage in Hertzian

Contacts and Life Ratings of Rolling

Bearings," Tribology Transactions, 51:4, 428-

445, 2008.

- ISO 281: (2007). Rolling Bearings—Dynamic

Load Ratings and Rating Life, 2nd Ed., 2007.

- ISO/TR 1281-2. Rolling bearings -

Explanatory notes on ISO 281-Part 2:

Modified Rating Life Calculation Based on

a Systems Approach to Fatigue Stresses, 11th

Ed., 2008.

- Gabelli, A., A.P. Voskamp, S. Shearer and

E. Ioannides. "The Service Life of Rolling

Elements Bearings - Stress Field and Material

Response Analysis," VDI Berichte Gleit Und

Walzlagerungen, 1380, 1998.

- Wendeberg, H. "Gearbox Bearing Service

Life – A Matter of Mastering Many Design

Parameters," AGMA 11FTM21.

- Vasconi, S. and D. Raju. "Virtual

Optimization of Epicyclical Gearboxes in

Wind Turbines," AGMA 12FTM06.

- Gabelli, A., E. Ioannides and E. Miglietta.

"Increased Life Performance of Rolling

Element Bearings in Gearboxes and

Transmissions," in Proc. of Int. on Gears,

VDI-Bericht 1230, Verein Deutscher

Ingenieure, pp.631-645, 1996.

- Gabelli A., A.M. Kerrigan and E. De Blic.

"HN-Treated Rolling Bearings for Extended

Service Life," Progress in Heat Treatment

and Surface Engine; Proceedings of the Fifth

ASM Heat Treatment Conference, Goteborg,

Sweden, 2000.

- Engel, L. and H. Winter. "Rolling Bearing

Damage," Antriebstechnik, 18, Nr. 3, pp. 71-

74, 1979, AGMA 14FTM16.

- FVA German Research Council for Driveline

Technology. Forschungsvorhaben No. 179,

"Partikelschäden," Final Report, 1992.

- Gläntz, W. "Contamination in Lubrication

Systems for Bearings in Industrial

Gearboxes," Ball Bearing Journal, 242, pp.

20-26, 1993.

- Nierlich, W. and J. Volkmuth. "Schaden

und Schadensverhütung bei Wälzlagern,"

Sonderdruck aus Antriebstechnik, 40, Nos. 1

and 2, 2001.

- Uherek, F.C. "Influences of Bearing Life

Considerations on Gear Drive Design,"

AGMA 05FTM17.

- Kasseris, E.P. "Comparative Analysis of

Automotive Powertrain Choices for the Near

to Mid-Term

- Future," PhD Thesis, Massachusetts Institute

of Technology, June 2006.

Printed with permission of the copyright holder, the American Gear Manufacturers Association, 1001 N. Fairfax Street, Fifth Floor,

Alexandria, VA 22314-1587. Statements presented in this paper are those of the author(s) and may not represent the position or opinion

of the American Gear Manufacturers Association.

Figure 1 Typical relative weight evolution in industrial gearboxes during the last 50 years (Ref. 6).

Figure 1 Typical relative weight evolution in industrial gearboxes during the last 50 years (Ref. 6). Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37).Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37).

Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37).Figure 2 Progress in automotive gearbox design in terms of increased torque density (Ref. 37). Figure 3 Typical progression of the ISO rated life of a radial ball bearing, loaded at C/P = 8;

contamination factor = 0.5; viscosity ratio of lubrication = 1 and 4.

Figure 3 Typical progression of the ISO rated life of a radial ball bearing, loaded at C/P = 8;

contamination factor = 0.5; viscosity ratio of lubrication = 1 and 4. Figure 4 Overview of different dynamic rating rules found in the market place; to simplify the discussion, of the competing product to the benefit

the life modification factor — aISO — is taken for all cases equal to 2.5.

Figure 4 Overview of different dynamic rating rules found in the market place; to simplify the discussion, of the competing product to the benefit

the life modification factor — aISO — is taken for all cases equal to 2.5. Figure 5 Schematic of a three stages helical gear unit and bearing arrangements.

Figure 5 Schematic of a three stages helical gear unit and bearing arrangements.

Figure 6 Overview of the modified life rating of the gearbox bearings normalized to the basic rating.

Figure 6 Overview of the modified life rating of the gearbox bearings normalized to the basic rating. Figure 7 Relative increase of bearing life as result of corrective actions about lubricant EP additives and improved cleanliness of the oil.

Figure 7 Relative increase of bearing life as result of corrective actions about lubricant EP additives and improved cleanliness of the oil. Figure 8 Example of stress field a) nominal smooth contact geometry, b) actual rough geometry

(Ref. 27).

Figure 8 Example of stress field a) nominal smooth contact geometry, b) actual rough geometry

(Ref. 27). Figure 9 Causes of rolling bearing failure as percentage of responses from an enquiry among the

companies of the FVA associations (Ref. 34).

Figure 9 Causes of rolling bearing failure as percentage of responses from an enquiry among the

companies of the FVA associations (Ref. 34). Antonio Gabelli is senior

scientist working at SKF

on tribology and rolling

contact fatigue life of rolling

bearings. He joined the

Engineering and Research

Center of SKF in Netherlands

in 1981, since than he

published many research papers on fatigue

and lubrication of rolling bearings. He was one

of the key contributors to the new bearing life

theory, developed by SKF in the 90's He is also

author of several patents on rolling bearings.

He holds a mechanical engineering degree

from the University of Padua (Italy) and a PhD

degree in from Chalmers Technical University of

Gothenburg (Sweden).

Antonio Gabelli is senior

scientist working at SKF

on tribology and rolling

contact fatigue life of rolling

bearings. He joined the

Engineering and Research

Center of SKF in Netherlands

in 1981, since than he

published many research papers on fatigue

and lubrication of rolling bearings. He was one

of the key contributors to the new bearing life

theory, developed by SKF in the 90's He is also

author of several patents on rolling bearings.

He holds a mechanical engineering degree

from the University of Padua (Italy) and a PhD

degree in from Chalmers Technical University of

Gothenburg (Sweden). Upon graduation in 1999

with a degree in mechanical

engineering from Technical

University of Compiegne

(UTC), France, Armel Doyer

joined SKF the following

year in the company's

development department for

deep-groove ball bearings.

He has since held various positions within

that department, focusing predominantly on

automotive and industrial applications, where

he contributed to SKF's first launch of energyefficient

bearings. Doyer since 2008 has been

working as a project engineer within SKF's

Industrial Drive organization, with a focus on

understanding industry technical needs and

in support of SKF's development towards the

industrial gear unit market.

Upon graduation in 1999

with a degree in mechanical

engineering from Technical

University of Compiegne

(UTC), France, Armel Doyer

joined SKF the following

year in the company's

development department for

deep-groove ball bearings.

He has since held various positions within

that department, focusing predominantly on

automotive and industrial applications, where

he contributed to SKF's first launch of energyefficient

bearings. Doyer since 2008 has been

working as a project engineer within SKF's

Industrial Drive organization, with a focus on

understanding industry technical needs and

in support of SKF's development towards the

industrial gear unit market. Guillermo E. Morales-

Espejel is principal scientist,

SKF Engineering & Research

Centre, The Netherlands,

and a visiting professor at

LaMCoS, INSA de Lyon. He

holds a PhD in tribology from

the University of Cambridge,

a "Habilitation à Diriger des

Recherches (INSA-Lyon),” and has15 years of

experience in rolling bearings. Morales-Espejel

has authored more than 50 scientific papers and

several book chapters with a focus on bearing life,

friction, lubrication and surface life.

Guillermo E. Morales-

Espejel is principal scientist,

SKF Engineering & Research

Centre, The Netherlands,

and a visiting professor at

LaMCoS, INSA de Lyon. He

holds a PhD in tribology from

the University of Cambridge,

a "Habilitation à Diriger des

Recherches (INSA-Lyon),” and has15 years of

experience in rolling bearings. Morales-Espejel

has authored more than 50 scientific papers and

several book chapters with a focus on bearing life,

friction, lubrication and surface life.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.