Voith Complete Drive Packages to Power Historic, 42-mile Overland Conveyor System

Atlas Energy Solutions has selected Voith Turbo to supply a total of 21 TurboBelt 800 TPXL fill control fluid coupling drives (including spares) to power 42 miles of conveyor belt as part of Atlas Energy Solutions’ historic Dune Express project. ELIN Motoren, a Voith company, will also provide 21 customized low noise electric motors for the project, including spares. Once in operation, the overland conveyor system will serve as a low-impact transport system, taking sand from Texas to New Mexico while establishing a new world record for a single conveyor flight without a mid-belt drive at an impressive 16.3 miles overall single flight length.

“As planned, the Dune Express is enormous,” said Roland Hoet, vice president sales, HDC Voith Turbo Americas. “Conveyor CV-004, the last in the system, will be the world-record holder, and combined with the three conveyors earlier in the line, this 42-mile conveyor system will be the longest in North and South America, and the second longest in the world.”

The system’s size is an important factor in the overall project, as it allows the system to positively impact its neighboring communities through the reduction in traffic congestion associated with sand delivery. To achieve this, the Dune Express addresses an explicit need for operations within Texas’ oil-rich Permian Basin: To limit highway traffic and road-safety concerns related to such an active venture.

Once in operation, sand will begin its journey from Atlas’ Kermit, Texas, facility and the Dune Express will carry material into New Mexico for storage or delivery. By powering the extensive conveyor system, Voith’s TurboBelt 800 TPXL coupling drives allow Atlas to eliminate millions of truck miles driven across the Permian Basin. This results in lower emissions within the communities where the sand would otherwise be carried.

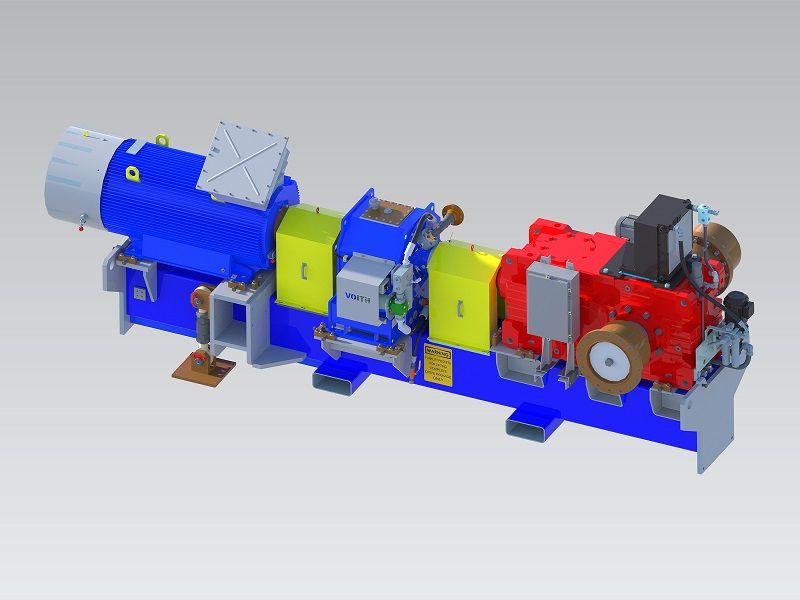

3D image of the complete 900 hp drive package for the Atlas Energy Solutions’ historic Dune Express project, including the TurboBelt 800 TPXL fill control fluid coupling drive which will power the conveyor belts and electric motors from ELIN Motoren.

3D image of the complete 900 hp drive package for the Atlas Energy Solutions’ historic Dune Express project, including the TurboBelt 800 TPXL fill control fluid coupling drive which will power the conveyor belts and electric motors from ELIN Motoren.

The multimillion-dollar project required significant technical work by Voith, ultimately developing seven different drive package designs for the install. Most significantly, the Voith drives needed to be designed to provide a specified acceleration time of 10 minutes for the conveyors. This extended start-up time was required to maintain belt tensions, especially along the lengthy horizontal curves for two of the system’s four belts. This start-up time is significantly longer than most large conveyors, which typically require 60 to 120 seconds.