“One week a band might be using the trailer in a cold northern climate, but the next week headed south for the Rose Bowl Parade,” said Hadley. “Such temperature extremes affect the fluid and can impact ramp folding, sequencing and deployment time, which requires frequent adjustment. Electric actuators are not subject to such variation and provide consistent operation, regardless of the environment and ambient temperatures.”

The electronic controls also made it easier to secure the ramp during travel or active loading. Each section of the ramp weighs 250 pounds and must be secured during both transport and operation. With hydraulic cylinders, once the power is off, there was still creep from seal leaks in these components, but the Electrak HD actuators have electronic hard-locking functionality that eliminates undesirable motion.

Smooth moves

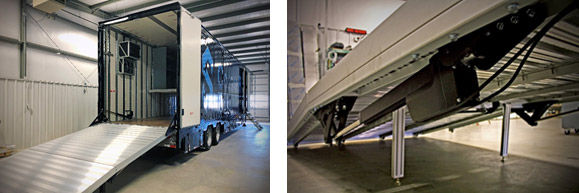

Figure 3: The synchronization feature of the Thomson Electrak HD helps coordinate smooth, safe and quick ramp operation.

The Electrak HD’s onboard electronics, combined with CAN bus networking, ensure consistent and synchronized movement of the ramp actuators. (Fig. 3)

“As the ramp deployment starts, the segments have to kick out to get things started and then flatten out over the move,” said Hadley. “With the hydraulic cylinders, each operates independently, so if there is any shifting of variation in the cylinder performance itself, you run the risk of the ramp buckling or twisting. The Thomson synchronization software harmonizes actuator operation, telling each actuator when to move to maintain balance. The same thing happens when it comes back up, and overall, the synchronization feature speeds up the whole ramp operation.”

Maintenance benefits

Eliminating hydraulic fluid itself also has many benefits. The Clubhouse team had been spending many hours hand-bending and mounting the stainless steel tubing necessary to bring the fluid to the hydraulic cylinders. The lightweight tubing is also subject to being crushed by instruments incorrectly strapped to the walls and, subsequently, hazardous leaks. With the Thomson actuators, all of the wiring is protected by nesting in the wall panels, under the floor or through the ceiling.

“With the Thomson actuators, we have reduced installation time by about 75 percent, and we don’t need band parents searching for hydraulic leaks from fittings during start-up,” said Taylor.

Innovating for convenience

Figure 4: Actuator synchronization enables operators to raise this moving floor up to increase storage space.

As they became familiar with the capabilities of the Electrak HD actuators, Taylor and Hadley began adding functionality to their trailers in ways they had never anticipated in their initial search for an alternative to hydraulics. Electric actuators have made it easy for them to offer customers new, unique options for any trailer project, including:

-

Moving Floor – The Electrak HD’s synchronization capability enables a section of the second floor to be raised smoothly to any desired height within a 16-inch range, allowing packers to optimize overhead and underfloor space. (Figure 4)

-

Power-retractable rear stairs – While previous rear stairs were spring-retracted, new, electric-driven stairs are easier and safer. (Figure 3)

-

Power-retractable front stairs – Once they had solved the retractable design for the rear stairs, replicating it for the front of the trailer made for a convenient new accessibility option. (Figure 4)

-

Tubavator – This electric lift extends out from an open street-side door of the trailer to simplify the loading of the band’s heaviest equipment, such as tubas, which can each weigh up to 85 pounds.

Partnering for innovation

In addition to product functionality, Hadley credits Thomson engineers for solving installation design challenges and helping The Clubhouse program the various smart features of the Electrak HD.

“When we were having trouble fitting an actuator assembly to the wall, Thomson came back with a design that rotated the motor 90 degrees,” said Hadley. “To enable us to mount actuators within our ramp frames while still connecting to existing mounting points, they added a four-inch extension to the actuator tube. To allow us to remove a damaged actuator, they gave us a way to unscrew the connector plug and leave the wiring harness in place for the next actuator. Whatever we needed, they were there with solutions.”

Figure 5: Electric-driven stairs have opened up new, safer accessibility options for The Clubhouse trailers.

Marching on

So far, The Clubhouse has deployed five different configurations of the Thomson Electrak HD actuator on various projects. One trailer, for example, is using 11 actuators — powering the ramps, front stairs, rear stairs, moving floor and Tubavator. The Clubhouse continues to build about 50 trailers per year, and with thousands of active high school, college and drum corps programs in the U.S., it is unlikely that their business will do anything but grow.

No one knows for sure which direction future band trailer innovations will take, but Hadley and Taylor are quite certain that electric actuators will be doing the heavy lifting.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.