The Automate trade show is committed to Detroit for 2022, 2023 and 2025 when it gets back to its biennial cycle post-COVID. “Detroit has a lot of interest in making sure our automated future has a space for everybody,” Burnstein added.

Launch Startups

The Cowen Startup Challenge, "Automate to Outperform" will take place on June 7, 2022. This year’s competition is sponsored by Cowen, a multinational, independent investment bank and financial services company. Companies entering the challenge must:

Operate in the automation space (robotics, vision, motion control, AI)

Been founded in the last five years

Raised less than $5 million USD since creation

Not be affiliated with or belonging to a larger group

Ten finalists will vie for the top $10,000 cash prize by pitching their technology solution to a panel of industry expert judges. All finalists will also be awarded a complimentary exhibit space on the Automate show floor to engage with more than 20,000 attendees.

“The imperative to automate has never been a higher priority across virtually every industry and we increasingly look to the innovative, bright minds from startup companies to lead the way,” said Peter Finn, managing director, industrial technology at Cowen. “Startup entrepreneurs play a critical role in the development of new technology, and this competition is a way for us to support and usher in new growth, while providing a spotlight for these new technologies in front of potential partners.”

Past winners include Innovative Mechatronic Systems B.V (2019) for its Archimedes Drive, a toothless gearbox; Apellix (2017) for its software-controlled aerial robotics; and Soft Robotics (2015) for its innovative gripping solution.

“There’s so much money that’s being invested in startups right now. This is a very unusual time in history for robotics and automation. I can tell you that there was a long stretch of time where people weren’t really looking to fund robotics. Now, it’s flipped. If you have a good idea in robotics, there’s venture capital available for it. Last mile delivery, any kind of advances in picking, all these machine advancements that are being discussed. This startup competition reflects the exciting changes taking place across the industry,” Burnstein said.

The ABB YuMi cobot is designed for a new era of automation where people and robots work side-by-side on the same tasks.

The ABB YuMi cobot is designed for a new era of automation where people and robots work side-by-side on the same tasks.

A Cultural Change

In the 1990s, the robotics and automation industries had its fair share of skeptics. There were concerns that the hardware couldn’t evolve like the software; there were affordability issues; a general feeling that the industries were never going to be as big or as profitable as people suggested.

“Now we’re seeing technology advances and companies able to afford investments because of new business models such as leasing, robots as a service, etc. Costs have come down and there is so much opportunity out there,” Burnstein said. “There’s all these new warehouses and distribution centers being built, for example, and they’re all going to be automated.”

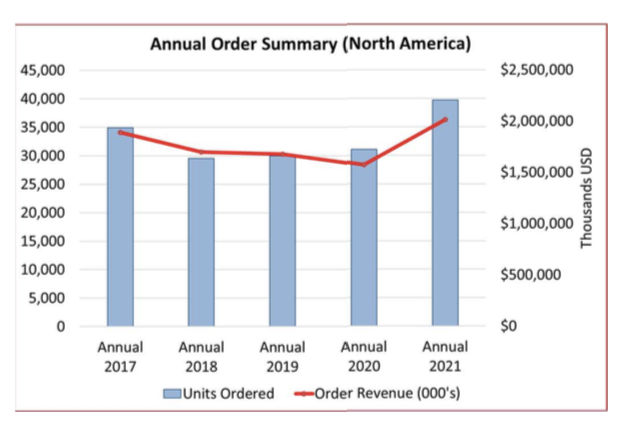

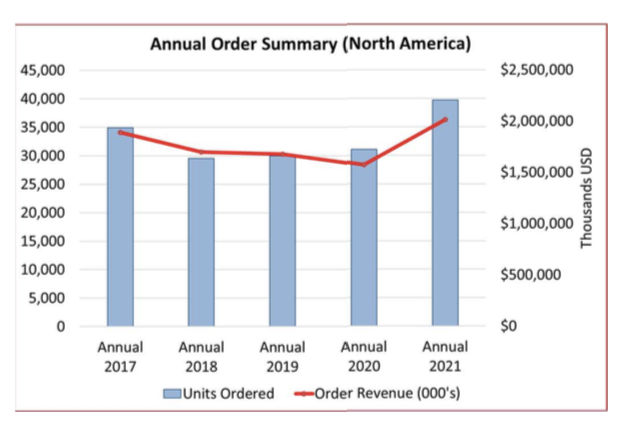

Annual order summary in North America for robotic units.

Annual order summary in North America for robotic units.

While many of these gains started within the automotive industry, Burnstein reflected on the changes that took place in 2020.

“In 2020, for the first time ever most robots ordered by companies in North America weren’t for automotive applications. It wasn’t that automotive was getting smaller, it’s just that these other spaces were growing. Areas like agriculture, construction, and restaurants. By next year, there’s going to probably be much more discussion on these emerging markets that really weren’t prominent a few years ago,” Burnstein said.

Additional areas where robotic and automation demands increased in 2020 included life sciences, pharmaceuticals, biomedical and food and consumer groups.

The PHD series offers seamless integration for Universal Robots that utilize standard PHD

The PHD series offers seamless integration for Universal Robots that utilize standard PHDpneumatic grippers.

Practicality & Purpose

The collaborative robot—or cobot—is a perfect example of how the industry is evolving. Here’s a robot intended to physically interact with humans in a shared workspace on the manufacturing floor. Burnstein said that people like what the promise of collaborative robots offer a manufacturing operation. “Smaller investments, quicker assembly, the flexibility to provide a safer working environment. Small to medium-sized companies can very easily find a situation where the implementation of a collaborative robot on the manufacturing floor will assist with a practical application.”

A3’s main objective is to provide companies with the information they need to apply these robotic and automation technologies. “This is accomplished with webinars, training sessions, case studies and trade shows like Automate,” Burnstein said. “The warehouse industry used traditional lift trucks, cranes, etc. ten years ago, but robotics and automation are playing a much larger role in that space today.”

How can collaborative robots benefit your operation? How can automation reduce manufacturing floor complexity? How can the industry simplify the tools to make these technologies more accessible? These are some of the questions that will be examined when the industry comes together in Detroit this summer.

“You need designers, installers, manufacturing leadership to play a role in this. It’s the people that are going to change the workforce in the future, and the robotic and automation technologies will reenforce these changes.”

automateshow.com

With its 3 kg payload, 400 mm horizontal and 200 mm vertical reach, the FANUC SR-3iA is ideally suited to smaller-scale robotic assembly, pick and place, inspection and packaging applications.

With its 3 kg payload, 400 mm horizontal and 200 mm vertical reach, the FANUC SR-3iA is ideally suited to smaller-scale robotic assembly, pick and place, inspection and packaging applications.