Whether driving a linear or dual wheel capstan, a requisite balance of torque and speed must be maintained to avoid slipping between the belts and the cable, thus ensuring both product quality and consistency.

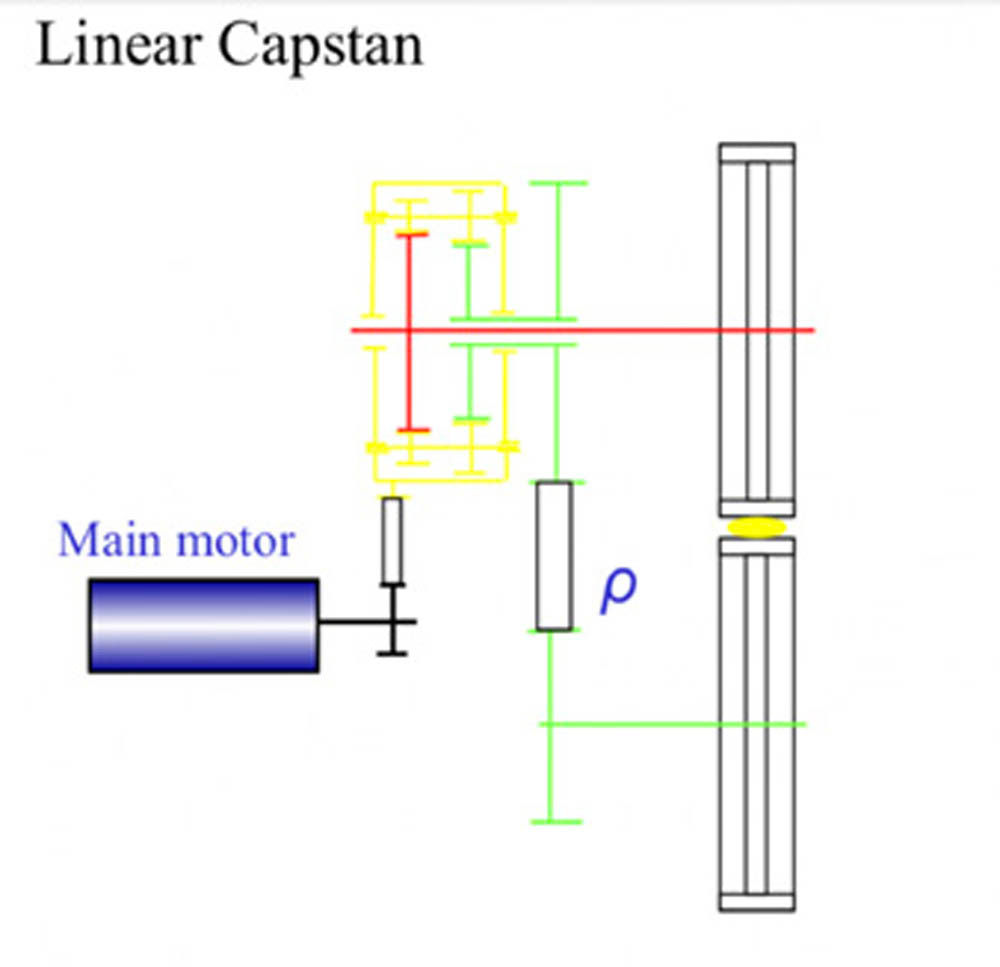

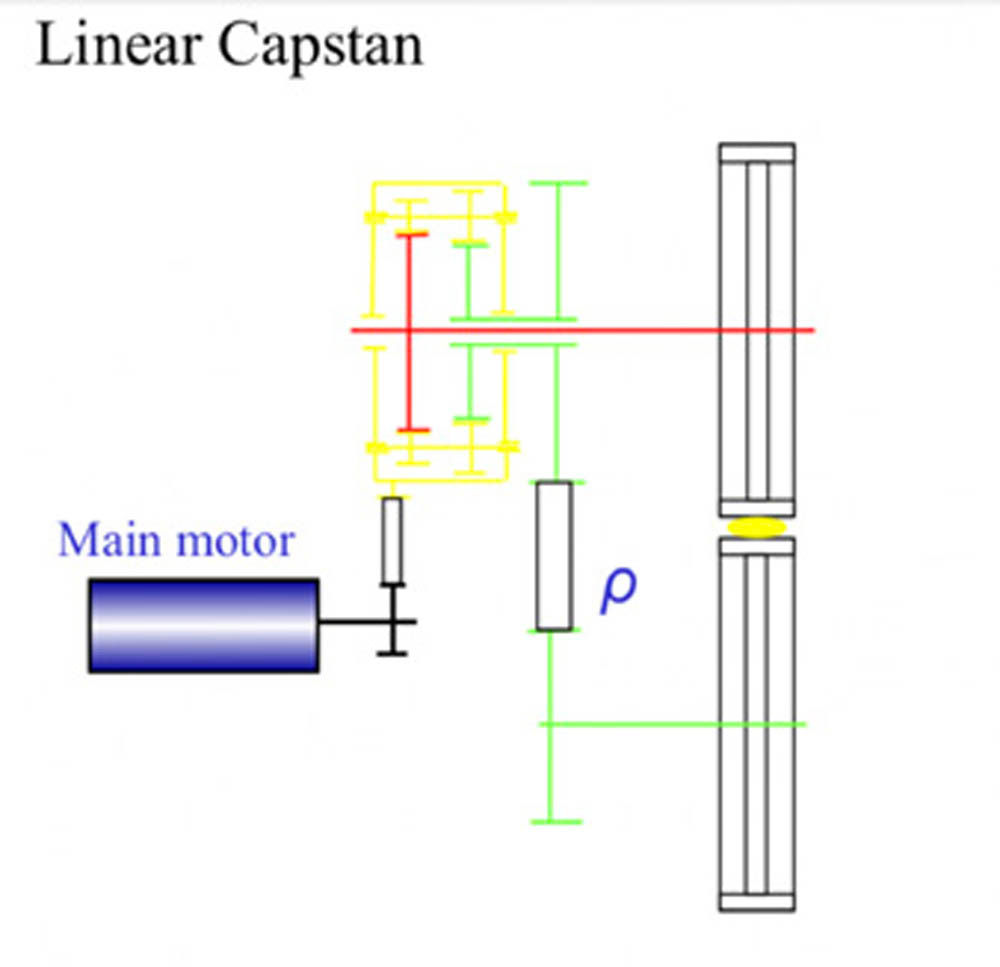

“Caterpillar”-type linear capstans employ two belts that rotate at the same speed to pull the product through the processing line at a constant tension. If the capstan’s cable tension is unstable, equipment used for extrusion, winding, paying off or other processes down the line will be out of sync, resulting in diminished product quality and possibly costly damage to the capstan itself. Because constant cable tension is essential, the system that drives the belts is critical to maintaining a processing line’s precision and, ultimately, delivering a better product. Here’s why the right drive system makes a difference in product quality:

You can drive a two-belt system by using a differential or employing a motor with two rigid fixed gear reducers. The gear reducer approach is prone to variations in the belt pulley’s diameter, which can cause the two belts to run at different linear speeds. Even the slightest speed differences will cause rubbing and slipping between the belts and the product, which in turn causes the products or the belts to wear. Depending on the application, belt replacement can get expensive.

Using the Redex SR differential with a linear capstan, the input speed defines the sum of the output speeds, and torque equilibrium ensures constant linear speed. The SR also automatically reverses the direction of rotation of the two outputs, thereby providing a reduction from the motor.

In a linear capstan, a differential with one input automatically reverses the direction of rotation between its two outputs and drives the upper and lower belts. This balances the torque between the two outputs and, consequently, balances the speed. If the belt diameters vary, the linear speed remains the same for the top and bottom belt. The result: no slipping and wear for the wire or cable. Taken together, the differential performs three functions in the linear capstan: It ensures a constant linear speed, reduces the speed and reverses the direction of rotation.

For a dual-wheel capstan, the wheels pulling the cable also must have identical torque, but the rotational speed can vary to accommodate diameter differences and maintain a constant linear speed between the wheels. Like a linear capstan, it also requires an effective driving method to maintain the necessary balance of torque and speed to avoid slipping between the belts and the cable.

For dual-wheel capstans, the differential balances torque and speed to ensure a constant linear speed between the capstan and the product, thereby preventing wear on the product or capstan wheels.

The SR differential from Redex USA is well-suited for this type of application, thanks to a compound epicyclic gearing design that incorporates two sun gears within the casing along with two gears for each planet axis. Redex’s patented assembly process ensures equal load sharing between the sun gears. It can be installed between the wheels using one input and two outputs. The output speeds can vary slightly to accommodate diameter differences on the capstan wheels. This differential corrects any variations in wheel diameters, eliminates transmission errors and drives the capstan wheels in the same rotational direction. This allows effective linear speed control and ensures precise pulling forces between the capstan wheels.

Tailor a Differential Gearbox to Meet Your Need

Redex USA has extensive technical expertise and customization capabilities to help you implement the best differential for the job. When you provide our experts with your force and speed requirements along with the pertinent measurements for belts and wheels, we can use that information to help determine a proper differential size as well as help calculate the speed of the motor to establish the differential’s gear ratio. Standard options include various timing belts or v-belts for the outer casing as well as coupling options.

High Torque and Speed Control Means Greater Cable Quality

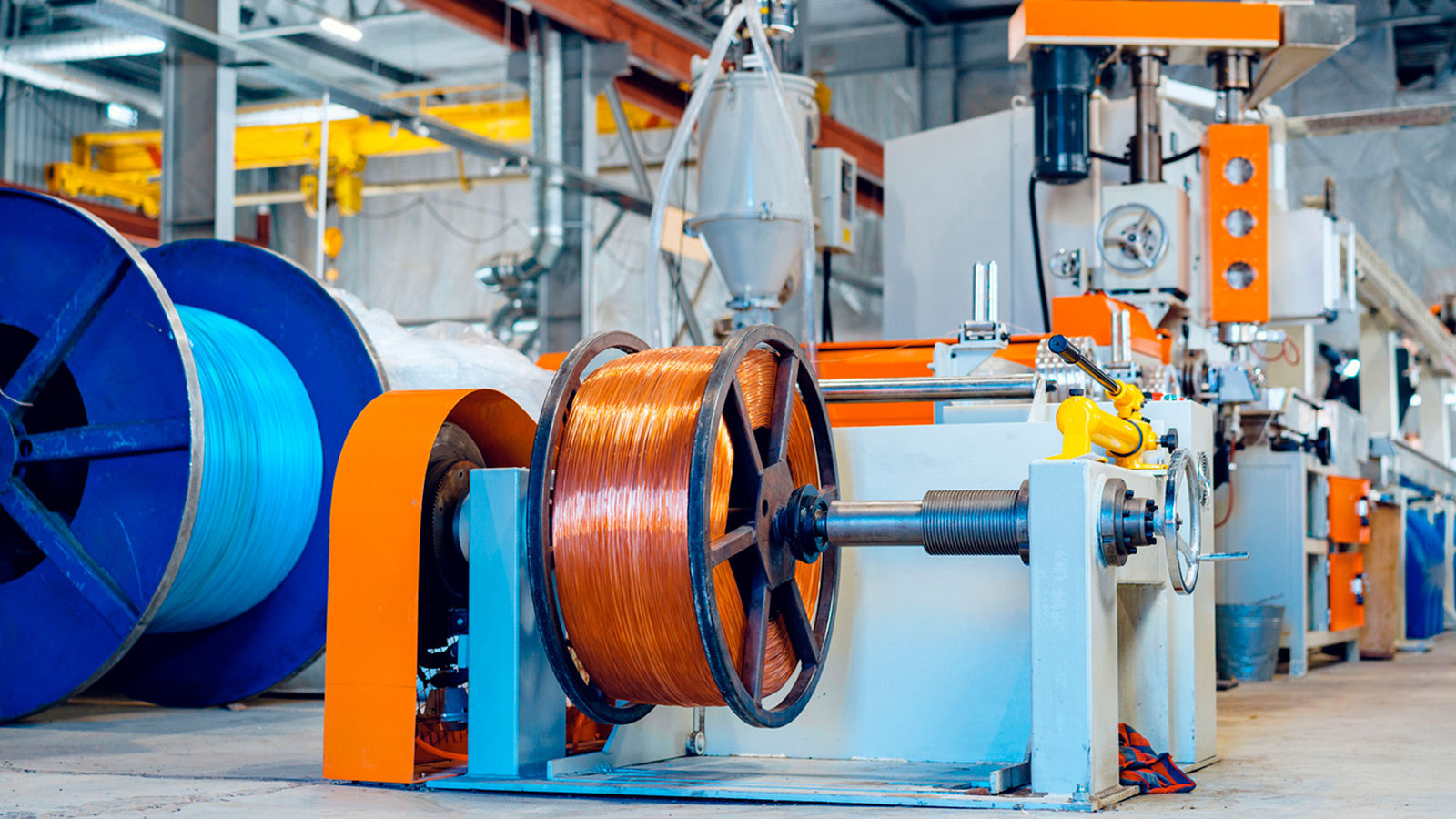

As you design new wire and cable manufacturing equipment to satisfy the growing need for specialty cables in the data center and EV industries, your success will depend on precise torque and speed control throughout your production line. Differential gearboxes deliver high torque output and speed control with exceptional precision, making them ideal for the wire and cable industry’s performance and product quality requirements.

Redex SR and SA differentials, with compound epicyclic gearing system and multiple planet trains, offer higher torque capability and a wide range of reduction ratios that ensure the greater precision and speed control that wire and cable production equipment demands. Redex sales engineers can help you determine the appropriate planetary gear reducer for your specialty wire and cable manufacturing application.

redexusa.com

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.