Aluminum Housing Series: Bearing Cup Fits in AL Housing

The interference fit that cups should have in an aluminum housing seems to be a subject that comes across my desk in regular intervals. Of course, there are numerous reasons why you would need certain fits in different areas. If there is a bearing cap involved, you may have a light or loose fit. If you need something that is going to be serviced at intervals, you are likely going to want a fit as light as possible. In gear housings, the highest priority is often the stiffness of the system, which drives a cup fit that you never want to lose contact because the cups will start to float in the bore creating misalignment in the shaft. In a perfect world, we could run a CAE stress analysis to determine how the cup interferes with the housing and then run a thermal study to make sure we hold our position at peak temperature, but as a great person once said, “Ain’t nobody got time for that.”

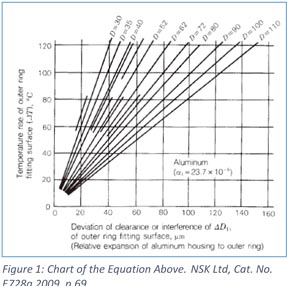

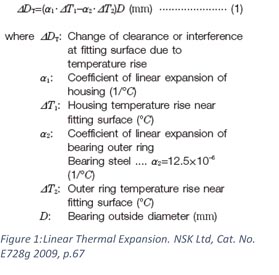

The bore expansion can be simplified to a simple diametrical expansion. It’s not 100% perfect, but its close enough for our purposes. A perfect calculation would use the linear expansion around the circumference, but when you use the same simplification to both the cup and cone, the end result is nearly identical as a more elaborate approach. Using this simplified equation, a 100mm bore at 120⁰C will expand by 85µm from room temperature, 25⁰C. If you were trying to maintain fit up to a 120⁰C; that is going to be your target interference fit. Depending on where your tolerances are, that might be your max. or min. target with your bearing + housing tolerance define the other end.

Next week we’ll discuss how to use hoop stress calculations to determine how much the cup will grow and shrink with moving temperatures. Don’t make the rookie mistake of using the 85 µm as your potential cup expansion. Your cup will only expand as far as you compressed it. In a 25mm wall housing, most of the interference is going to expand the housing wall with the cup only compressing by as little as 1/5th of the overall interference.

Tune in next week, we have much to discuss!