Force Control Oil Shear Crane Brake Solves Maintenance Headache

Brake Upgrade Fixes Manufacturing Challenges at SAF

Working three shifts around the clock throughout the week doesn’t leave time in the schedule for production downtime in Southern Aluminum Finishing’s anodizing line in Atlanta, Georgia. However, they found themselves frequently grinding to a halt as their crane brakes demanded continual maintenance.It was a constant headache for Josh Berris, general manager for the Atlanta Branch: a brake would fail every other week, to the point that Berris dedicated a member of his team largely to repairing brakes. Due to the heavy loads and amount of use, the dry brakes needed weekly repair.

“We were rebuilding parts all the time and replacing brakes. We were activating them far more than they were meant to be,” Berris said.

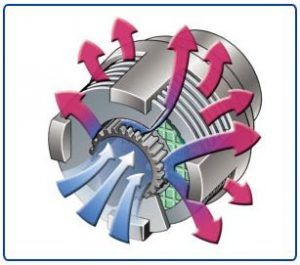

MagnaShear Assembled Brake (photo courtesy of Force Control).

Rather than just keep rebuilding the dry brakes, Berris decided to replace them entirely with brakes that use oil shear technology from Force Control Industries. With the new Magna Shear Brakes, the anodizing line is back up and running, 24 hours a day, 5 days a week—without fail.

The crane is used to manually guide parts through the anodizing process, with continual starting/stopping/jogging parts into position and moving them through. Each crane has a capacity of 1 ton and has independent front and back action, performing up to 20 clicks per move, and many hundreds of moves per shift.

To stop and position the load, Baldor 5 hp motors are mounted with brakes. Previously, SAF employed dry brakes which needed constant maintenance. Dry brakes employ a sacrificial surface – the brake disc or pad – to engage the load. Without a good way to remove the heat caused from engagement between the disk and plate, this sacrificial material absorbs the extremely high temperatures, which degrade the friction material.

Oil Shear Technology from Force Control.

As the friction surface wears away and begins to glaze, the spring force is also reduced, causing torque fade. This causes positioning errors that typically require adjustment or replacement of the friction surface. Manual “jogging” engaged the brake multiple times per move, wearing down the dry brakes quickly. Small linkage pieces within the brake operation also tended to wear, corrode, and hang-up from the anodizing chemicals.

Brake repair was more than just a nuisance though. All that downtime added up to serious backups and loss of production time. The cranes are setup with two overlapping brakes, so SAF can operate with one crane, but with limited productivity—as much as 30% less efficiency.

Oil-shear technology plays a major role in ensuring that the cranes on the anodizing line operate continuously. A film of automatic transmission fluid flows between the friction surfaces, and as the brake is engaged, the fluid is compressed. The automatic transmission fluid molecules in shear transmit torque to the other side. This torque transmission causes the rotating surface to slow, bringing it to a stop. Since most of the work is done through the fluid particles in shear, by the time the surfaces actually meet or “lock up” wear is virtually eliminated. This means that no adjustment is needed – Ever! This is a tremendous maintenance cost and downtime savings.

In addition to transmitting torque, the ATF also helps to dissipate heat, due to a patented fluid recirculation system. Along with torque transmission and heat removal, the fluid also serves to continually lubricate all components such as bearings, splines, etc. – thus extending their service life. Oil Shear Technology also provides a “cushioned” stop that reduces shock to the drive system – further extending service life.

Unlike dry friction brakes, the totally enclosed oil shear system is impervious to external elements such as wet, dusty, dirty, or corrosive environments. Since the layer of fluid eliminates wear, the MagnaShear motor brake provides an incredibly long service life.

Though the initial purchase price was higher than the dry brake they were replacing, the brakes have paid for themselves several times over in longevity and subsequent savings from forgoing replacement brakes and parts. By avoiding brake failures and production downtime for maintenance, the MagnaShear brakes have kept up with the high production standards that SAF demands to maintain its reputation of excellence. Learn more about MagnaShear Brakes here:

https://www.forcecontrol.com/products/brakes/motor-brakes/magna-shear-motor-brakes

Article contributed by Jim Wahl (Wahl Marketing) and Stan Porter (Force Control Industries)

For more information:

Force Control Industries

Phone: (800) 829-3244

www.forcecontrol.com

Southern Aluminum Finishing (SAF)

Phone: (404) 355-1560

www.saf.com