According to Joshua Smith, controls engineer at JDM, “Our team anticipated that by replacing our three-phase AC motors with brushless DC motors, we could significantly increase power within the same space.”

The Nautilair blower, featuring Neodymium magnets, operates more quietly and efficiently. The design of the blower's eight backward-curved fins further boosts performance, reduces noise, and maintains effective cooling.

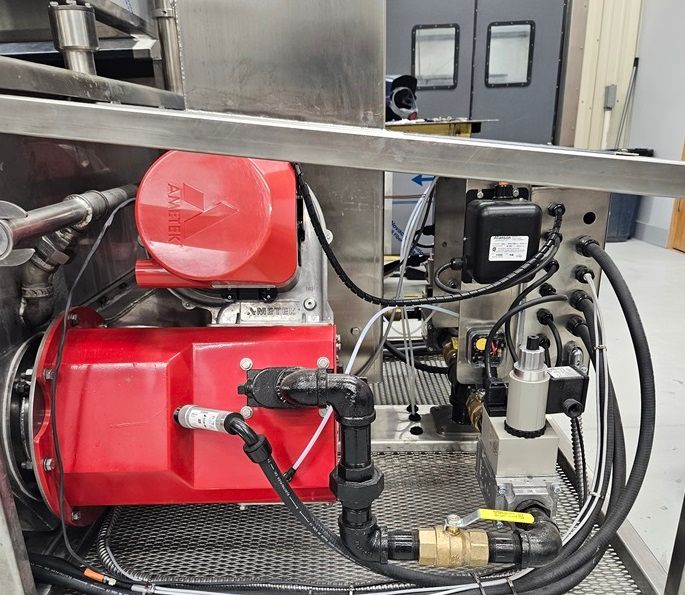

Smith remarked, “The power density is astounding. We upgraded from a 1 hp AC motor to a 7.5 hp DC motor, all within the same space.” He also emphasized that the new blower integrated seamlessly into their existing system, requiring no modifications to the enclosure, power supply, or other components. Since its installation, the Nautilair blowers have operated flawlessly.

One issue arose when the induced voltage from the fryers’ ignition transformers, which convert 120-volt power to 6,000 volts to ignite the burners, interfered with the electronics of the Nautilair BLDC drive. This issue was resolved through collaborative troubleshooting with JDM and Bison engineers by electrically isolating the ignition transformers.

During the investigation, Bison applications engineers recommended enhancing the blowers with Bison's upgraded silicone electronics coating to extend their lifespan in harsh operating conditions. Through this collaborative effort, the Bison team released a new model specifically designed to meet these demanding requirements.

Inspiration – What’s Next?

An important advantage of the Nautilair blowers is their BLDC controllers that allow for the modulation of blower speed.

Smith highlights that "this innovation significantly enhances our fryers, providing precise control at both low and high flame levels, as well as during pilot conditions. This results in substantial financial benefits for our customers through reduced fuel consumption and increased efficiency, all while minimizing environmental impact.

"We are planning the integration of Nautilair blowers into our smaller units, aiming to extend these benefits across our entire product line. This strategic move underscores our commitment to delivering high performance, environmentally conscious solutions that meet the evolving needs of our customers," stated Smith.

The Results

The seamless integration of Bison’s Nautilair 12.3" Combustion Blowers, with its remarkable power density, has enabled JD Manufacturing to exceed their high-performance standards, ensuring efficient production.

Even with installation that has the complex exhaust flue configuration with the 315-degree directional change, the switch to the Nautilair blower has significantly increased air pressure, boosting production to 585 pounds of kettle chips per hour — a 17 percent improvement. Other installations are producing 600 pounds per hour.

"The power density of the Nautilair blowers has made a huge difference for our customers," emphasizes Smith. "It empowers them with significantly higher productivity, reliability, and yield in their operations."

jdmanufacturinginc.com/

bisonametek.com/