Bearing Life

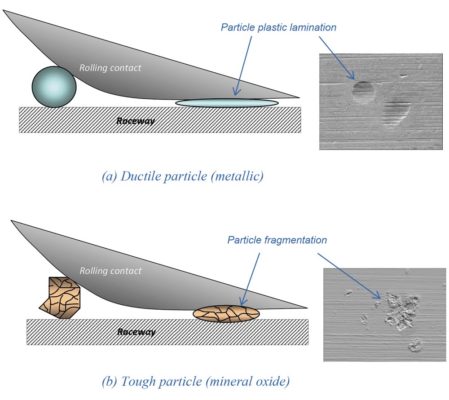

Spindle Bearings—Potential Damaging Mechanisms and Mitigation

Exploring contact conditions in both steel-steel and hybrid ceramic bearings

Read More

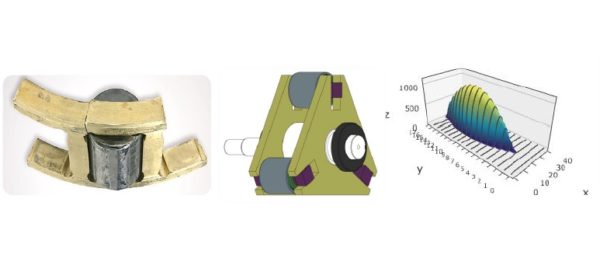

Building a Better Bearing

An innovative look at analysis, condition monitoring, mounting and maintenance.

Read More