Bearing Failure

Wholesale Changes in Electrification and E-Mobility

Quick Hits from The Bearing Show and Lubricant Expo North America 2024

Read More

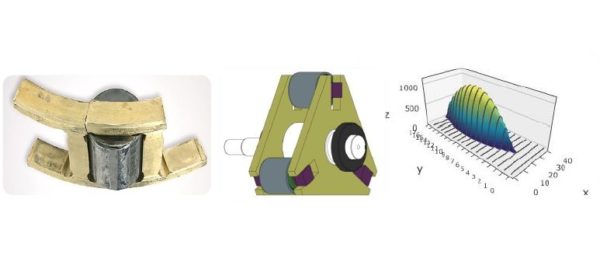

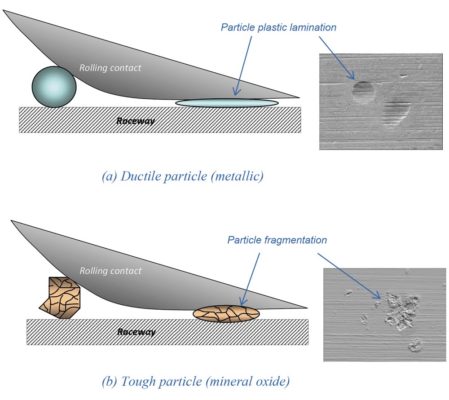

Spindle Bearings—Potential Damaging Mechanisms and Mitigation

Exploring contact conditions in both steel-steel and hybrid ceramic bearings

Read More