Couplings

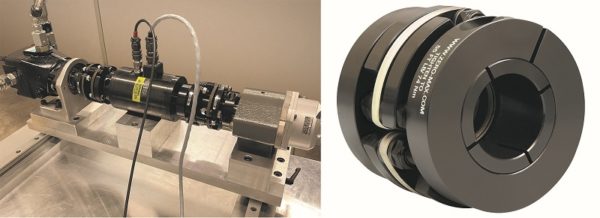

Electric pre-shredder provides energy efficient option with MAV shrink discs

Read More

A Preview of the 2022 Turbomachinery & Pump Symposia

A vital industry event for rotating-equipment engineers and technicians worldwide

Read More

Using and Specifying Flexible Couplings

Prepared by members of the AGMA Flexible Coupling Committee

Read More