Food & Beverage

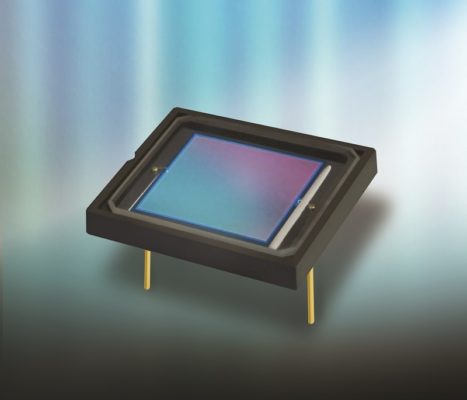

Bearing Design Considerations for the Food Processing Industry

Materials, closures and lubrication options must be properly selected to ensure the optimal performance of bearings used in this machinery.

Read More

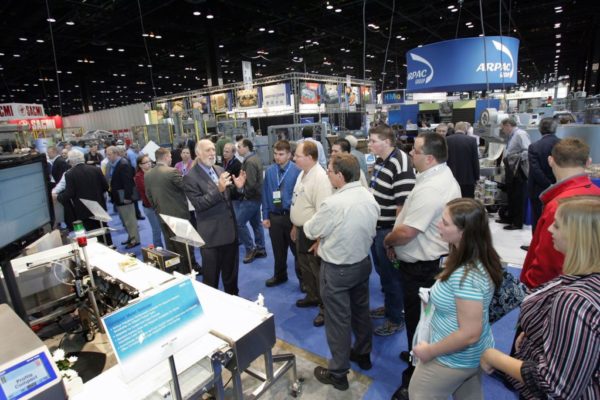

Automation, Robotics and Mechatronics at Pack Expo 2022

Chicago trade show offers innovative packaging and processing solutions

Read More

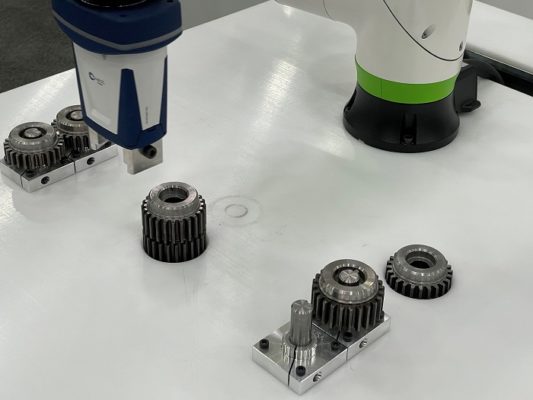

A Guide to Gear Automation

Robotic technologies are designed to handle everything from heavy payloads to miniature components

Read More

Kollmorgen Examines Functional Safety

Why it Matters and How to Achieve it with SafeMotion

Read More