New Innovations in Motion Control

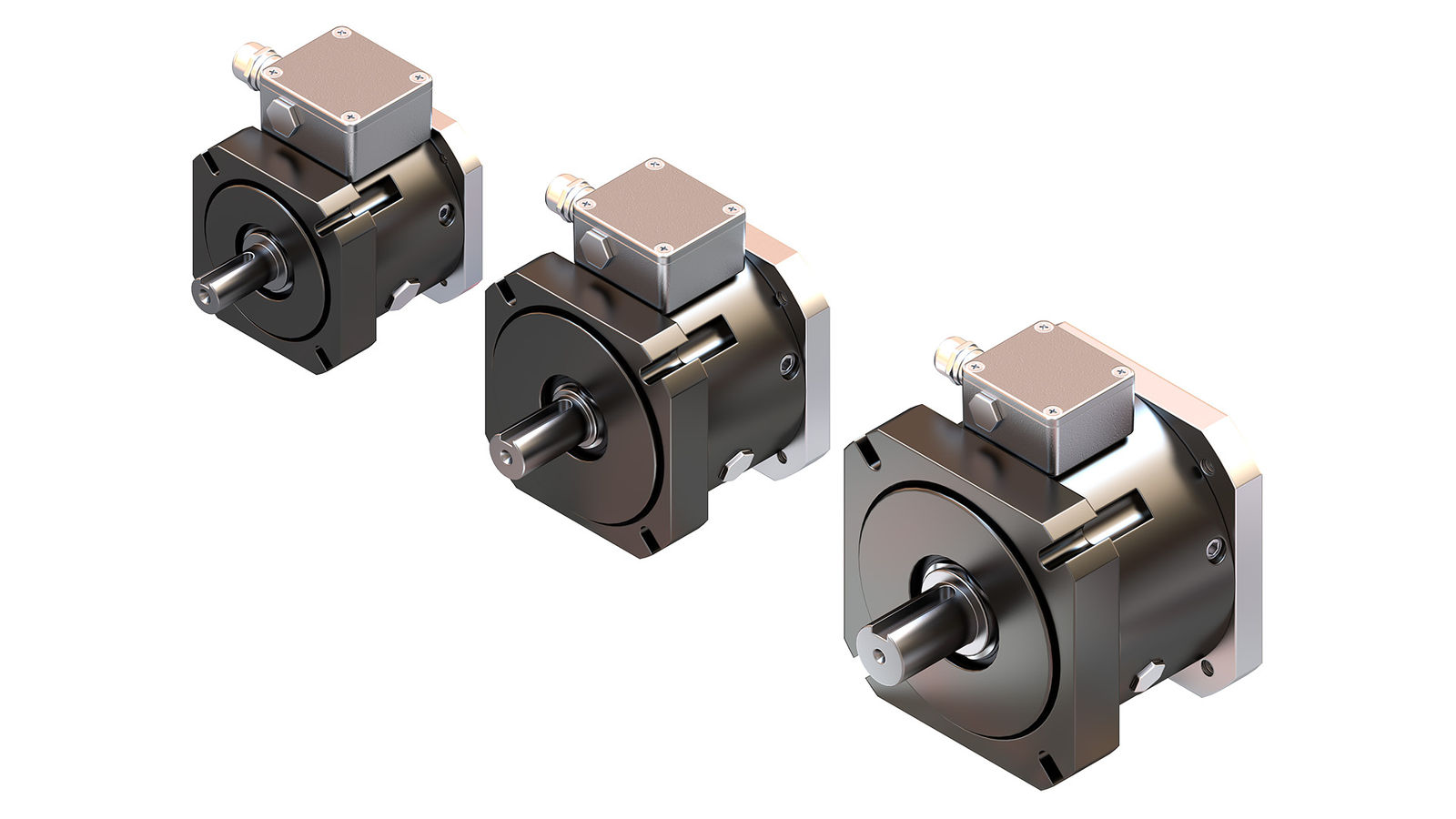

Nexen designs braking solution with zero backlash up to the full holding torque in a rigid, easy to install product

Previous discussions with engineers at Nexen examined the challenges and increased complexity of components for machine designers in industrial machinery.

“Historically, Nexen Group’s product offerings were mechanical and pneumatic solutions, including clutches, brakes, torque limiters, and coupling products for industrial machinery that needed to control power transmission,” said Justin Zollner, design engineer at Nexen. “As Nexen expanded into precision motion control applications, the need for zero backlash drive solutions became increasingly important. In addition, many motion control applications are limited to only electric drive solutions. These two overlapping needs were the driving force of the Evolve Electric Servomotor Brake line.”

Functional Safety

System stiffness and rigidity, in addition to torque requirements, are primary factors in selecting a servo system brake solution. Functional safety is becoming a key factor in the decision-making process, which focuses the system designer on a solution’s B10 and B10d ratings to ensure it meets the overall design intent.

Functional safety is about reducing the risk of human injury or death posed by the use of machinery in the face of operator error or mechanical failure. Building functional safety requires the design and fabrication of protective features that mitigate against the threat of worker injury. Protection systems should be designed to respond to human errors, hardware failures, operational or environmental stress.

Nexen understands that functional safety standards and industry requirements are evolving. The focus is to provide more safety focused components for machine builders. Functional safety is, in fact, becoming more prevalent. The need for monitoring and diagnosing problems thru internal machine trouble shooting will be vital as factories become more and more automated.

Sizing and Selecting a Brake Solution

Nexen engineers collaborate with customers to size and recommend solutions using all the products in Nexen’s extensive catalog, including the newly released Evolve line.