Efficiency and performance are essential for EV motors. Smaller, lighter packages that offer the same power output as larger units is necessary.

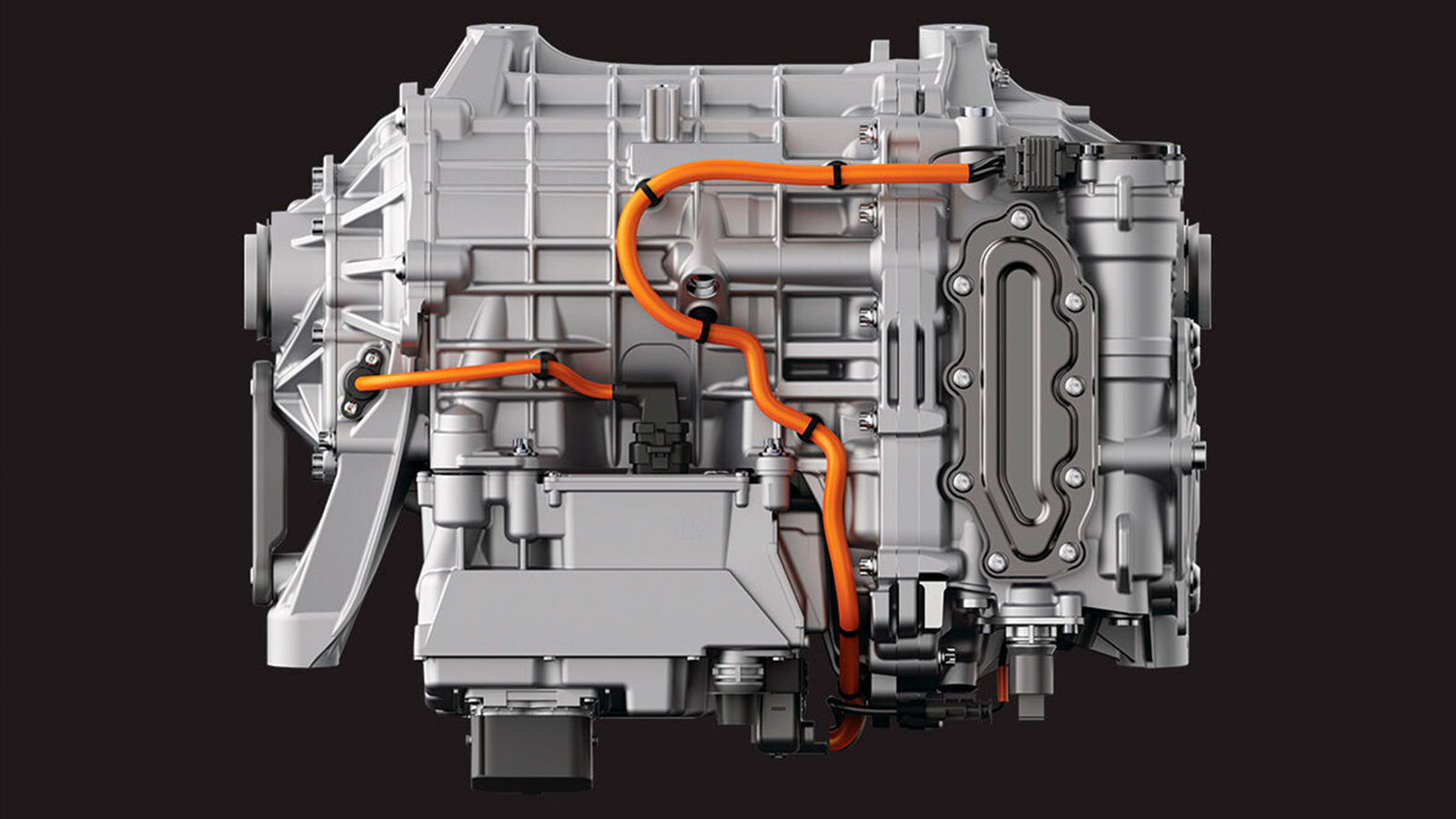

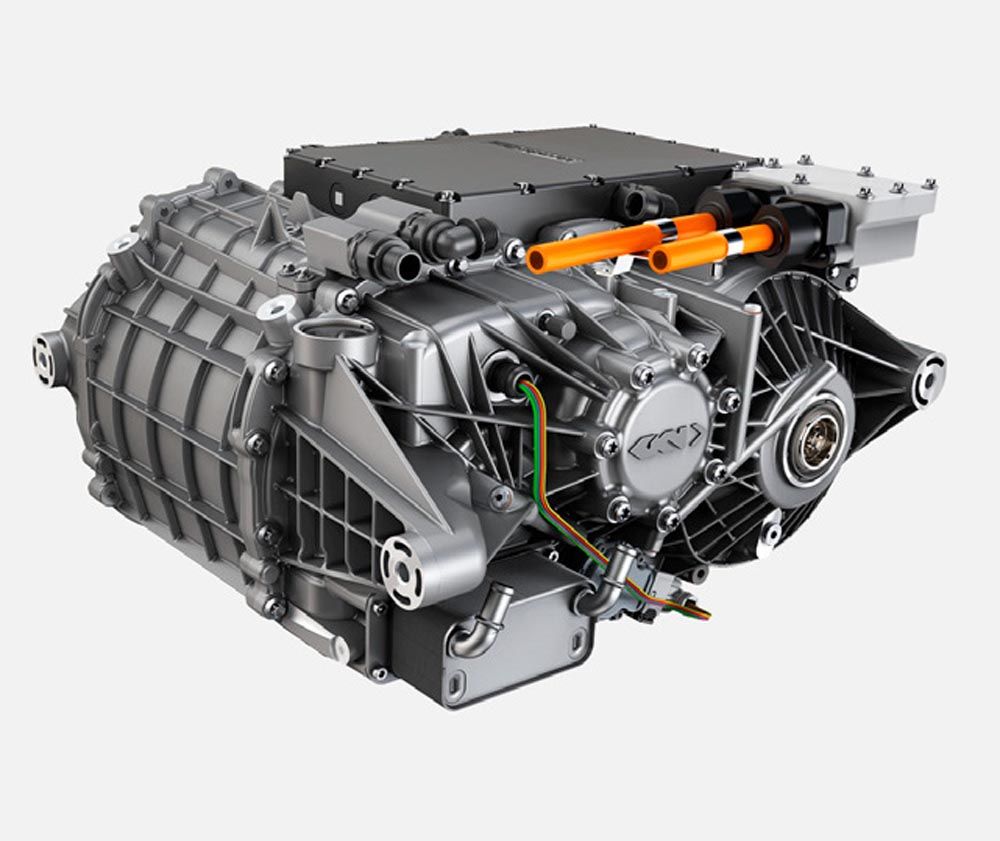

By creating a modular and scalable electric drive (eDrive) system—consisting of the inverter, motor, and reducers (single- or dual-speed)—we can fulfil customer requirements for a wide range of vehicles. We can, for example, use three standardized motors to offer a power range of between 60 and 300 kW, depending on the customer’s requirements.

Our second area of focus is around how the torque is managed from the drive unit, distributing it across the vehicle, from front to back, left and right, from axles to wheels.

Higher torques occur in an EV drivetrain because of the instant power availability. Open differentials and limited slip differentials help us to manage this torque and improve traction and control, depending on drive style and conditions.

The initial focus was on open differentials, then mechanical limited slip for enhanced torque transfer, then differential lockers for off-road trucks. We moved into more managed devices that include electronics and software, such as electronic limited slip differentials (eLSD) where the clutch manages each wheel’s torque on one axle in a very detailed way, and eventually to twin-clutch all-drive devices for full independent torque transfer to each individual wheel on the axle. eLSDs not only improve the traction and stability of the vehicle, but also significantly improve its agility.

Our last area of focus is on transferring the torque to the wheels. In a standard internal combustion (ICE) vehicle, the power is typically distributed from the engine at the front, across the axle to the wheels.

However, in an EV, rear-wheel or all-wheel drive is favored, meaning that we need to look at the effect this has on drive components as the weight distribution shifts from the front axle to the center.

EV side shafts are significantly shorter than those in ICE vehicles, requiring different mounting points and larger installation angles. As a result, we are seeing increased plunge distances as well as changes to basic requirements for the constant velocity joints (CVJs).

These driveline components must withstand higher vehicle mass, greater acceleration torques, and up to 1,200 Nm of braking force to enable key technologies like regenerative braking. Despite their shorter length, EV side shafts must be stronger and more durable to withstand the vehicle’s extra weight, while avoiding a significant increase in size to remain as efficient and cost-effective as possible.

Side shafts play a significant role in transferring torque efficiently from the axle to the wheel. As a rotating part, these parts are often a contributing factor to noise, vibration, and harshness (NVH) performance, to which EVs are particularly sensitive due to their low noise profile compared with ICE-powered vehicles.

It is vital that our product development is sustainable for years to come. As such, across the whole of the product development process, we are looking at developing alternative technologies. One example of this is the development of alternatives to rare earth magnets within the motors, to remove these materials altogether.

Other factors we must consider as we improve and enhance products are the reduction of copper in the motors and inverters, the origins and chemistry of the steels we use, and the lubrication oils and their source.

Not only that, but we must also consider our energy consumption as we produce the parts, ensuring we are continuing to sustainably manufacture driveline components that are fit for the future.

With forecasts indicating that future EVs will have a longer lifetime than today’s ICE vehicles, improving durability is essential to the vehicle’s longevity. This must be done without compromising efficiency, and crucially without adding even more weight. Therefore, a pragmatic approach favoring balanced system design with the lowest possible material consumption is vital to manufacturing in a way that supports a cleaner, more sustainable future.

gknautomotive.com