ZF Celebrates Production of Three Million Electric Motors

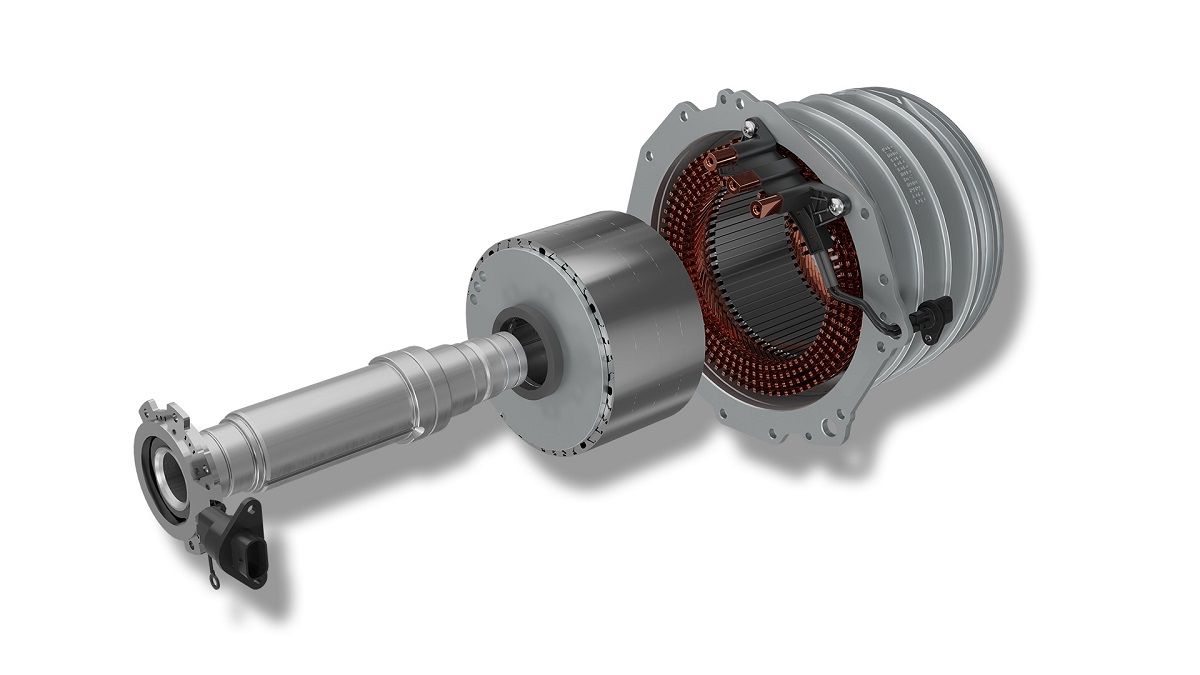

ZF has produced more than three million electric motors, a technology that is used worldwide in electric vehicles. ZF covers a broad spectrum of vehicle electrification: from purely electrically powered passenger cars and plug-in hybrids to electric drives for commercial vehicles. The production anniversary stands for a continuous reduction in the dependency on pure combustion engines as well as for the successful transformation to electromobility.

The global demand for electric drives for passenger cars and commercial vehicles is increasing rapidly – and so are ZF's production figures: "Within just 18 months, ZF has doubled electric motor production from just under one and a half million to three million," explains Roland Hintringer, head of the electric motors product line at ZF, adding: "Thanks to highly automated, volume-flexible and modular systems, we are able to serve our global customers as required."

Further innovations for more efficiency and range

The production figures and forecasts make it clear that ZF is successfully advancing the transformation towards electromobility. "Our role as an innovator is also an important factor," emphasizes Hintringer. ZF has already announced that it will develop the magnetic-free electric motor I²SM – a separately excited synchronous machine with inductive energy transfer – for volume production which, in contrast to the magnetic-free concepts available on the market today, is uniquely compact and has the highest power and torque density. ZF has recently demonstrated the potential of ZF's new developments for further efficiency and thus range gains in electromobility with the EVSys800 electric drive: The prototype is 35 percent lighter than current electric drives and reduces CO2 emissions in production and operation by 20 percent. Innovative stator winding technologies, a new cooling concept and the compact design make these major optimization leaps possible.

Worldwide production locations

ZF already produces electric motors at locations in Asia and Europe; production facilities are currently being installed in North America. The company thus serves the major automotive markets at the following locations: Hangzhou and Shenyang (China), Pancevo (Serbia), Schweinfurt (Germany), Trnava (Slovakia), Saltillo (Mexico), and Gray Court (USA). The capacities of the electric motor production facilities at the existing production locations are currently being expanded in order to best support the customers' ambitious sustainability and climate protection targets.