KISSsoft Offers Plastics for the Calculation for Cylindrical and Crossed Axis Helical Gears

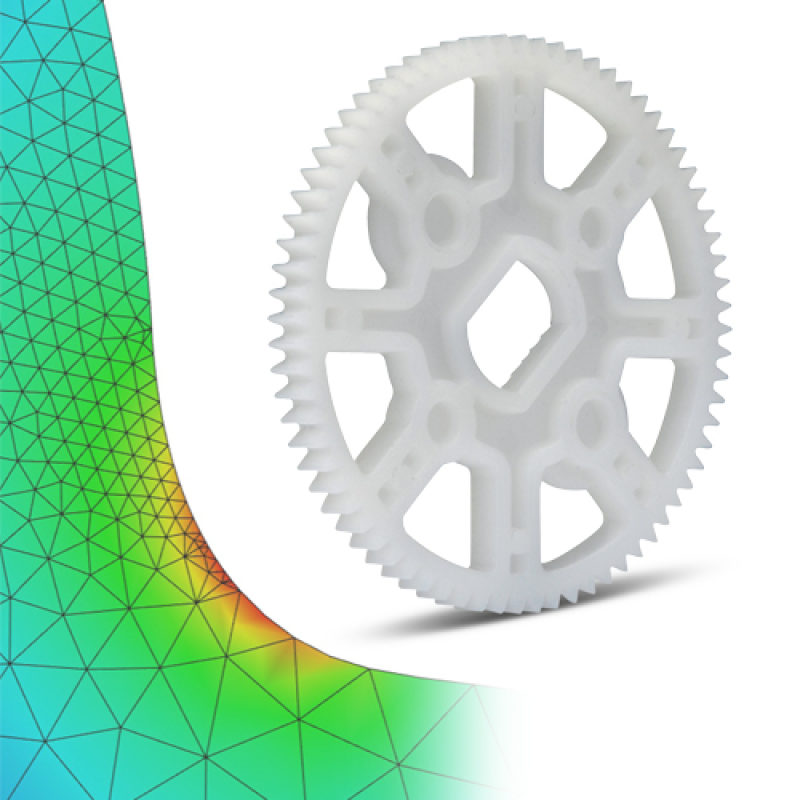

From opening the sunroof in your car, pumping insulin in a medical device, aligning solar panels in a satellite to moving toy cars, plastic gears are widely used in small gearboxes. In many cases, plastic materials can provide a good alternative to steel because of its low weight, good damping properties and lower cost for serial production.

The strength of plastic gears greatly depends on their temperature. Determining required material properties for the design of the gears takes a lot more time and effort than for steel gears, as the properties have to be measured at different temperatures.

In KISSsoft, 97 (yes, ninety-seven!) plastics are available for calculation of cylindrical and crossed axis helical gears. The materials range from unreinforced POMs and PAs to high performance reinforced and internally lubricated materials. This range of plastics covers properties from VDI 2545 and VDI 2736 which are essential for the analysis of strength, wear and vibrations. KISSsoft enables the calculations according to VDI methods, as well as using contact analysis, “Pech” wear calculation and tooth root form optimization through FEM.