ABM Drives Offers Bevel Gearbox Units

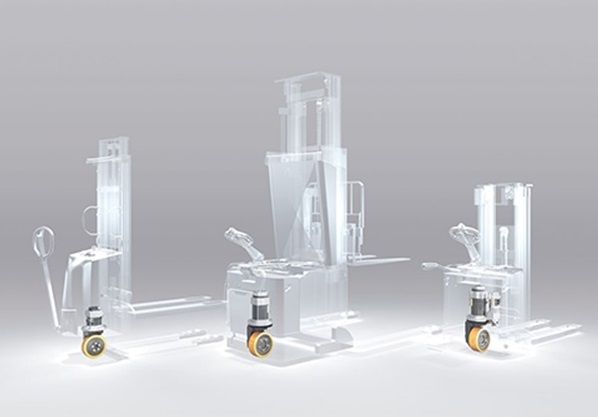

Electric drives in conveyor systems, lifting equipment, and forklifts are the motors that drive modern, efficient, and reliable intralogistics. ABM Drives Inc. develops and manufactures platform-based systems for stationary and mobile applications. ABM works closely with customers to build drive solutions, including motors, gearboxes, brakes, and frequency inverters tailored for specific applications.

“Traction, lifting, and steering in forklift trucks, for example, require both know-how and the right drive components,” says Mayk Krüger, senior manager of material handling at ABM. “Our solutions consistently comply with strict environmental requirements, are particularly safe, and enable precise movements even at low speeds thanks to their high responsiveness.”

ABM supplies all drive components, including motors, gearboxes, sensors, brakes and inverters for many applications. ABM develops and manufactures complete gearbox–motor drive units in-house. Additionally, ABM supplies the right modular system solution for the right vehicle type.

“Our drives make dynamic movement and precise maneuvering of industrial trucks possible for users, even in tight spots,” Krüger says. “Also, our solution provides forklift trucks with excellent climbing performance.” The TDB series easily integrates into a given application via plug-and-play. The two-stage, bevel-helical gearbox drive unit offers high performance and low energy consumption for manual and electric industrial trucks. Bevel-helical gearboxes have high power density and outstanding efficiency. Combined with a steering drive and equipped with a fully integrated and reliable sensor monitoring system, users receive a fully integrated traction and steering drive solution. “Through the vertical design, the small envelope size, and the numerous series options, this gearbox drive unit is ideal for many applications – for example, in reach trucks, tow tractors, automated transport systems, and sweeper/scrubbers,’ says Krüger. Users can work reliably for lengthy periods, even with smaller batteries.

Various Steering Options

ABM offers bevel gearbox drive units for 9-in. and 10-in. wheel diameters based on power output, speed, and load capacity: Gearbox ratios and motor performances can be tailored precisely to given applications. The compact TDB series offers drive torques of up to 750 Nm. “It is equipped with various steering options,” says Krüger. The manual steering system, for example, is suitable for direct mounting on the drawbar. The user receives a space-saving, robust, and long-lasting solution. ABM can supply a zero-position sensor for the steering position and an absolute encoder for steering right on the traction gearbox if necessary. A third possibility is an integrated electric steering drive. The user benefits from redundant steering monitoring, maximum ride comfort, and increased safety.