Huco Oldham Couplings for Rotary Positioning Stages

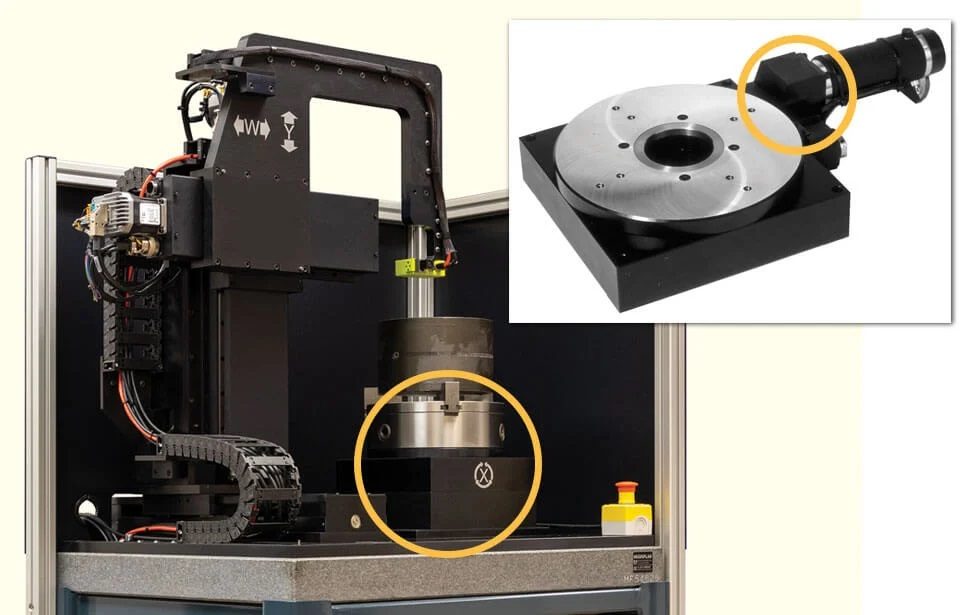

Racaw Ltd., a designer and manufacturer of precision positioning components and systems, required reliable shaft couplings for use on its lines of linear and rotary positioning stages. The stages allow precise linear and rotary positioning of objects via a stepping or servo motor with rotary encoder control.

A precision worm and wheel (rotary stage) or ball screw (linear stage) provides repeatable, near zero-backlash positioning. The coupling is positioned between the stage’s electric drive motor and the drive element. Rotary positioning stages are utilized in a range of precision machines, including laser scanners that accurately measure the surface topology of large bearings (shown above).

Huco Oldham couplings were selected because they met Racaw’s torque capacity range, zero backlash, auditable noise and vibration levels, lengthy predicted service life and availability requirements. Oldham couplings can handle faster movement rates without starting to ‘ring’ under high acceleration and deceleration. In contrast, a beam coupling driven harshly can act as a torque spring and create both noise and vibration.

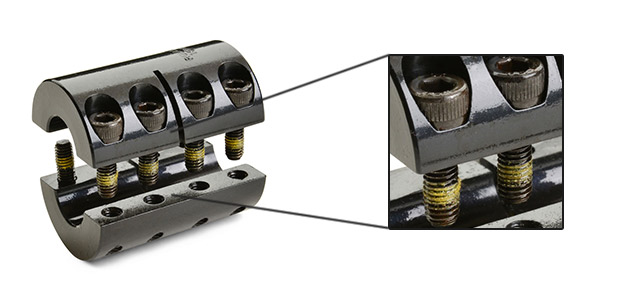

The Huco Oldham coupling design transmits torque through a central disc that slides over tenons on the hubs under controlled preload conditions. Huco supplies complete 3-part Oldham couplings to meet specific rotary positioning stage requirements, including custom bores. The through-bore couplings are comprised of two aluminum clamp-style hubs and an acetal disc that provides high torsional stiffness and long, backlash-free life.