More Than Just Motor Size

Use Application Information to Size Your Gearbox Correctly

When a right angle gearbox is subjected to a higher torque or horsepower load than its rating, the overload situation will eventually shorten its lifetime. If the overload is mild in severity, the gearbox may operate normally for some period before the increased wear makes replacement necessary.

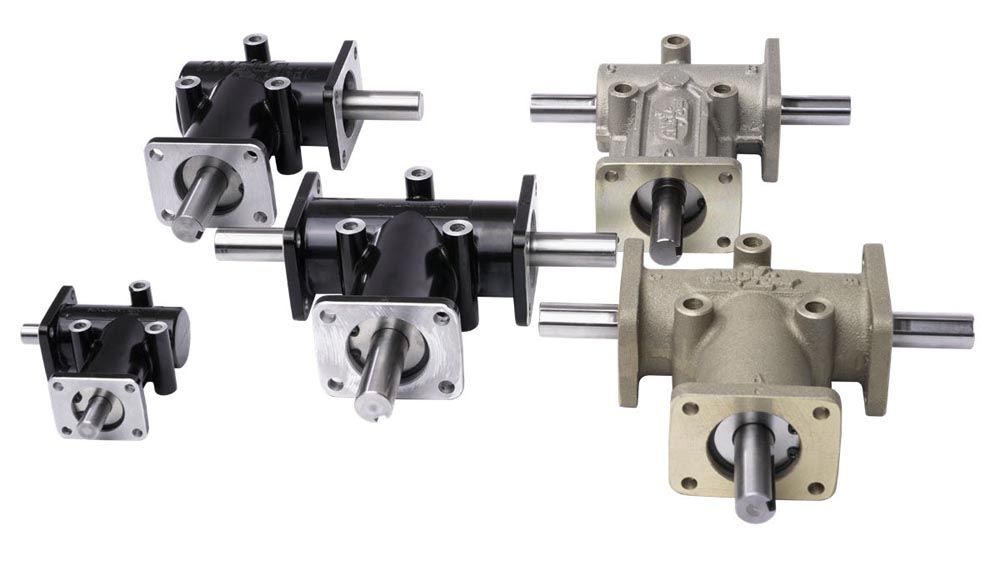

When your equipment calls for a right angle gearbox, proper sizing makes a difference. A wide range of application factors must be considered, or you will face problems down the road. Possible problems can include increased maintenance, worn teeth and reduced mean time between failure (MTBF). Additionally, an oversized gearbox will cost more money than necessary. This article will provide an overview of how to apply application information to accurately size an Andantex Anglgear right angle gearbox for your installation.

Determine Your Target Speed and Output Torque

To begin sizing, determine the horsepower or torque that must be transmitted in the application. Next, you must consider how fast the output shaft will turn to meet your requirements. Additionally, we must consider both the axial and radial loads applied to the gearbox shafts.

As power and torque requirements increase, the gear set diameter will also increase to transmit the larger forces. As the gearset grows in diameter, the gearbox housing must grow to accommodate the larger gears. Knowing the power and speed, you can always calculate the torque. Or, by knowing the torque and speed, you can calculate the power. The formulae for determining torque and horsepower are shown in Table 1. The axial and radial load ratings can be found in Table 2.

When a right angle gearbox is subjected to a higher torque or horsepower load than its rating, the overload situation will eventually shorten its lifetime. If the overload is mild in severity, the gearbox may operate normally for some period before the increased wear makes replacement necessary. Severe overloading can result in damaged bearings, broken gear teeth or both. When the axial or radial load ratings are exceeded, it will shorten the life of the bearing thus reducing the between-gearbox replacement. Therefore, some gearbox specifiers may be tempted to size the gearbox to the drive motor, resulting in an oversized gearbox.