Bosch Rexroth Offers Complete Battery Production Solutions

Bosch Rexroth will present its latest automation, material transport and assembly technology products and solutions for battery manufacturing in Booth #1553 at The Battery Show North America and Electric & Hybrid Vehicle Technology Expo, September 13-15, in Novi, Mich.

With working demonstrations, product exhibits and industry specialists, Bosch Rexroth will present a broad portfolio of manufacturing technology and expertise tailored to meet complex battery production automation requirements.

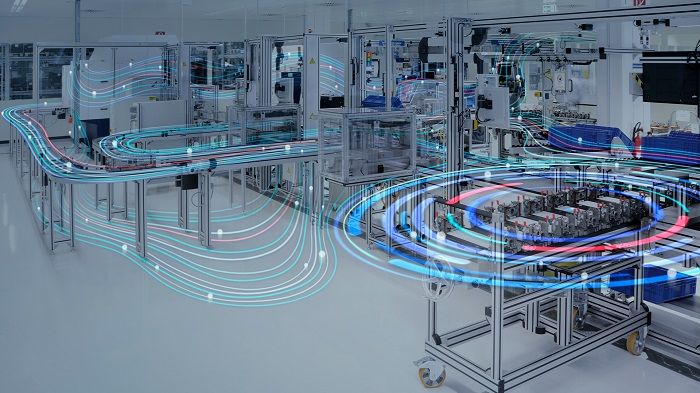

The Battery Show North America and Electric & Hybrid Vehicle Technology Expo is North America’s largest and most comprehensive advanced battery manufacturing trade show. Bosch Rexroth will showcase how its industry-leading technologies — including ctrlX AUTOMATION controls and drive systems, robust and proven TS conveyors, linear motor-powered Flexible Transport System and plug-and-produce Smart MechatroniX offerings — can intelligently and seamlessly integrate into complete automation solutions, helping battery manufacturers get products to market faster through open, scalable production platforms.

Key booth highlights and interactive exhibits include:

Transfer Systems Demo: Battery manufacturers must move a wide range of loads through complex production steps. This demo shows how Bosch Rexroth conveyors and transport systems can address multiple material handling challenges, from cell to battery pack, combining innovation with efficiency and flexibility.

The working display integrates the Flexible Transport System (FTS), a linear motor pallet transport system that provides higher transfer speeds and more precise pallet positioning, with the TS 2plus twin strand pallet conveyor into an efficient and versatile material transport solution. The FTS offers fast and independent bidirectional motion of two pallets on a track, which can operate asynchronously or together. Key features are its high pallet positioning accuracy, micron level repeatability and ease of programming for independent carrier movement.

The display also uses a working Rexroth ctrlX CORE controller to operate the transport system, highlighting the ctrlX CORE’s performance characteristics, ease of programming and connectivity.

Smart Function Kit for Handling: Another working demo showcases the features and benefits of the Smart Function Kit for Handling, with a multi-axis linear robot that can be configured by booth visitors using Bosch Rexroth eTools software without the need for special programming. The exhibit will show how plug-and-produce Smart Function Kit combinations can be easily sized, configured and ordered as one part number. In addition, the Smart Function Kit for Handling uses the Rexroth ctrlX DRIVE servo drive to highlight the system’s fast commissioning and servo drive auto parameterization capabilities.

IndraDrive Mi and ctrlX DRIVE Demo: This exhibit shows the combination of Bosch Rexroth’s compact drive system and cabinet-free drive technology. The scalable ctrlX DRIVE platform is the world’s most compact modular drive system, covering both simple single-axis applications and complex multi-axis machine systems. All system components can be freely combined by the user for faster implementation. The IndraDrive Mi cabinet-free technology enables machine manufacturers to integrate all electrical drive components directly into the machine vs. a control cabinet, resulting in a smaller machine footprint and more scalability.

Bosch Production Tools: Visitors can interact with and learn more about the EXACT ION and ANGLE EXACT ION cordless shut-off screwdrivers for manual tasks such as battery pack connection assembly. Featuring improved ergonomics and lithium-ion batteries for long run times, the EXACT ION series allows battery pack assemblers to optimize fastening processes, improve quality and reduce costs.

Nexo Torque and Angle Tightening Tools: This interactive demo lets visitors see the advantages offered by the complete Nexo system, including the Nexo cordless nutrunner, socket selector and operator guidance software (OGS) for tightening multiple bolts. The HMI provides clear instructions to guide part assembly and automatically enables the tool as the user works through the process.

Educational Highlights: The booth will also feature a new, 3D animated video sequence, highlighting the major production steps in battery cell assembly, along with the complete range of Bosch Rexroth open automation, mechatronics and transport systems to improve all these process steps.