PBC Linear Expands Miniature Metric Ball Screw Assemblies

PBC Linear has expanded its comprehensive portfolio to include Miniature Metric Ball Screw Assemblies. Building on their lead screw technology, this combination of precision-rolled screw and compact nut is driving exceptional performance from an economical package. Manufacturers of sophisticated laboratory equipment, medical devices, semiconductors, and other automation applications will find these high-precision ball screws a valued solution to their small-scale linear motion needs.

In addition, PBC Linear offers shorter lead times, which is accomplished through their ball screw production process and central Midwestern location, where many of their products are engineered and produced.

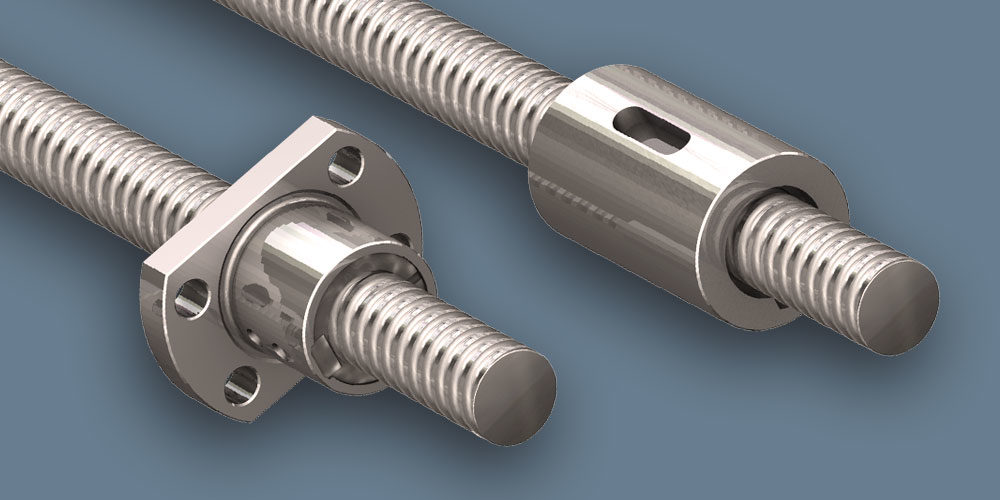

As with lead screws, ball screw assemblies are used to convert rotational motion to linear motion. They typically include a ball nut, threaded shaft, and a recirculating system that utilizes a continuous movement of balls to transfer forces and propel the nut along the screw. Each ball screw and nut are engineered with gothic arch threads that define the track of the nut and screw thread, offering high rigidity, durability, and duty cycles. The main benefit of ball screws is higher efficiency and accuracy, making them ideal for a variety of industrial and automotive applications.

PBC Linear currently offers miniature ball screws in diameter sizes of 6 mm, 8 mm, and 10 mm, with options for lead length and nut type. In addition, standard and special machined journals can be provided for unique customer requirements. Other options include fixed or floating end blocks.

The other half of the ball screw assembly consists of the nut. Miniature metric ball screw nuts from PBC Linear feature two types of ball return systems to accommodate shorter or longer leads. Short leads are synonymous with internal multiliner returns, and long leads are represented in the company's endcap return system. Each are available in flanged or cylindrical configurations, with optional end support blocks and bearings. Flange style nuts can often be easier to remove and install in an assembly, provided the assembly can be designed so that the mounting screws or bolts can be easily accessed. Cylindrical nuts allow for a more compact assembly design as there is no flange.

Dynamic load ratings are an important factor when determining the correct miniature ball screw for an application. PBC Linear will provide conservative dynamic load rating values within this product family, based on 1,000,000 Rev (N). This ensures trusted, reliable performance for those looking to implement miniature ball screws into their systems. Ball screws from PBC Linear come standard without preload (backlash clearance held to 0.05 mm MAX). They offer a preload option that offers higher rigidity and better positional accuracy, but at the expense of slightly diminished load capacity. This P-type preload uses oversized balls to preload the assembly up to three percent of dynamic capacity.

PBC Linear ball screw assemblies meet the standard ISO accuracy for grades 10 and 7. In addition, customers can contact an application engineer regarding Class 5 accuracy. To meet industry requirements, PBC Linear utilizes high-end testing equipment such as Keyence optical comparators, Mitutoyo thread form tracers, and custom dynamic lead checkers that analyze up to 15,000 points per meter.

PBC Linear uses a high-precision CNC roll threading process for the most consistent thread forms and high accuracy rate. They also measure and record 100 percent positional accuracy along the entire travel length of the screw.