bonfiglioli.com

Xtek Focuses on Engineering Expertise

Xtek products can be found anywhere durability is needed for the most demanding applications in industries ranging from steel and aluminum production, to mining and energy, and more. The company, headquartered in Sharonville, Ohio, provides high-quality custom machined and heat-treated parts and component assemblies for heavy-duty industrial processes.

Founded in 1909, Xtek was known as the Tool Steel Gear & Pinion Company. A young inventor, Russell Bloomfield, was seeking a way to make cup and cone bearings for bicycles that could take the harsh pounding of the period’s cobblestone streets. Bloomfield’s work led to the development of a steel hardening process that eventually became known as the Tool Steel Process (TSP) because the metallurgical properties that it imparted to gears and bearings made them “as hard and as durable as tool steel.”

Founded in 1909, Xtek was known as the Tool Steel Gear & Pinion Company. A young inventor, Russell Bloomfield, was seeking a way to make cup and cone bearings for bicycles that could take the harsh pounding of the period’s cobblestone streets. Bloomfield’s work led to the development of a steel hardening process that eventually became known as the Tool Steel Process (TSP) because the metallurgical properties that it imparted to gears and bearings made them “as hard and as durable as tool steel.”

The original focus of the organization was on gears for traction cars. Later, the company applied its metallurgical techniques to heavy-duty equipment applications in railroads, mines, and steel mills.

Through the decades, Xtek has evolved into a manufacturer of custom engineered components for a wide range of industrial applications. A recent blog on the company’s website detailed the variety of engineering expertise that makes the organization better with materials, customized heat treatment options, and finish machining techniques.

Xtek boasts a diverse lineup of engineering expertise with backgrounds in mechanical, manufacturing, materials science, electrical, aerospace, biomedical and industrial engineering.

Application engineering: providing analysis (FEA, etc.) on parts and assemblies, analyzing application requirements, and offering design recommendations.

Design engineering: applying industry standards to product development, and creation of manufacturing and detail drawings.

Manufacturing engineering: developing manufacturing processes and programming for all CNC equipment.

Service engineering: reverse engineering application components, offering upgrade recommendations and determining repair specifications.

Metallurgical engineering: conducting material failure analysis and specifying material composition and heat treat process selection.

With such diverse expertise, it’s not surprising to hear that the company recently retired a mill pinion after 58 years of service. This set of carburized mill pinions for a major European hot strip steel mill was manufactured in 1964. Although it had some minor surface wear, it was still in great condition considering the timeframe.

xtek.com

Altra Highlights Heavy-Duty Upgrades

Engineers at Nuttall Gear and Delroyd Worm Gear spend many shifts reverse-engineering equipment in harsh, heavy-duty environments. Whether it’s a gearbox or gear drive, maintenance managers meet with application engineers to determine the best course of action to keep steel mills running optimally to avoid downtime.

Nuttall Gear Rebuilds Enclosed Reducer for Steel Processing Line

A major steel producer needed an upgrade to a straightener gear drive. The service requirement on the existing drive was increased which caused the heavily loaded gear in the train to fail due to overload. Driven by a 500 hp motor, the straightener pulls strip steel through two sets of rollers that relieve stresses while straightening the coil.

Nuttall Gear provided the upgraded gear drive based on their long-standing working relationship with the customer and their reputation for designing and manufacturing robust steel mill gear drive solutions.

Nuttall Gear provided the upgraded gear drive based on their long-standing working relationship with the customer and their reputation for designing and manufacturing robust steel mill gear drive solutions.

The rebuilt drive featured a reduction ratio of 1:1, a 1.25 service factor with a 160 rpm input and 160 rpm output. The gearing upgrade to the affected components was changed from through-hardened gears to carburized and ground gears for enhanced wear resistance and improved shock load capacity.

Delroyd Worm Gear Solves Drive Failure for Screwdown Mill Stands

The gear drives for screwdown mill stands at a major steel mill in Ohio were failing prematurely causing extensive downtime. The worm gear teeth were wearing and breaking down at an accelerated rate due to improper meshing at the contact zone. The problem created excessive pressure at the gear’s pitch line/contact zone.

Delroyd engineers met with the hot mill managers to conduct an on-site inspection and short-term mill stand monitoring period. Through these efforts, it was determined that the cause of the drive failures was that three different gearing manufacturers had supplied gearing, all with different thread designs, which were being mixed and matched over time.

Delroyd engineers met with the hot mill managers to conduct an on-site inspection and short-term mill stand monitoring period. Through these efforts, it was determined that the cause of the drive failures was that three different gearing manufacturers had supplied gearing, all with different thread designs, which were being mixed and matched over time.

A spare worm and gear sample was sent to the Delroyd facility so that a new gearing solution could be reverse engineered to ensure that all gear sets installed on the hot mill stands would have a matching thread/tooth design. The new Delroyd gearing solution extended the gearing life from six months to more than six years.

Delroyd Worm Gear Develops New Gear Set for Steel Mill Charging Crane

Gearboxes for a charging crane hoist drive were failing prematurely at a large steel mill in Northeastern U.S. The failures were causing unfavorable outages and expensive periods of downtime.

Due to their desire and reputation to solve problems, Delroyd was called in to help analyze the situation and develop a solution. A meeting was held at the mill with various parties including an outside service group, mill engineers, maintenance managers and Delroyd engineers. All aspects of the ongoing issues were reviewed and an on-site inspection of a failed gearbox was performed.

Based on their findings, Delroyd engineering developed new worm gear sets utilizing aluminum bronze gears and redesigned the bearing mountings to enhance strength and durability. A carburize hardened, ground, and polished alloy steel worm develops a smooth, work-hardened surface on the aluminum bronze gear. Extra-heavy side plates were used to connect the worm and gear shaft bearing supports, assuring proper meshing of the gear under all conditions of load. A more rigid fabricated steel housing design was utilized to reduce bending moment stresses. A redesigned, more efficient lubrication system was also incorporated.

Based on their findings, Delroyd engineering developed new worm gear sets utilizing aluminum bronze gears and redesigned the bearing mountings to enhance strength and durability. A carburize hardened, ground, and polished alloy steel worm develops a smooth, work-hardened surface on the aluminum bronze gear. Extra-heavy side plates were used to connect the worm and gear shaft bearing supports, assuring proper meshing of the gear under all conditions of load. A more rigid fabricated steel housing design was utilized to reduce bending moment stresses. A redesigned, more efficient lubrication system was also incorporated.

The Delroyd design changes resulted in extending the gearbox life by over five years. The charging crane gearbox success prompted the mill to utilize Delroyd’s expertise by providing gearboxes for their gantry cranes as well.

altramotion.com

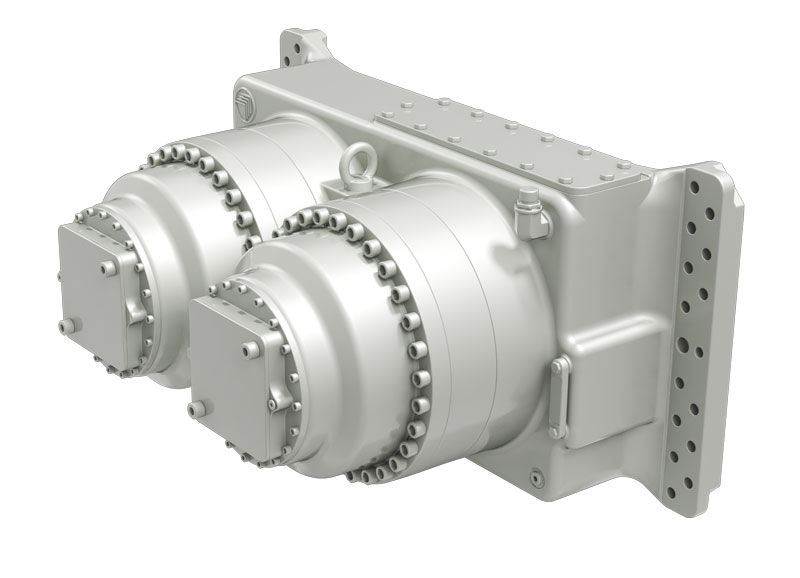

This kind of product modularity and flexibility is found in Bonfiglioli’s Planetary Series (300). The 300 series is compact and powerful, excelling in areas where shock loads and impacts are more the rule than the exception. The product configuration is highly versatile, due to several options for mounting, gear layout, output shaft and motor interface.

This kind of product modularity and flexibility is found in Bonfiglioli’s Planetary Series (300). The 300 series is compact and powerful, excelling in areas where shock loads and impacts are more the rule than the exception. The product configuration is highly versatile, due to several options for mounting, gear layout, output shaft and motor interface.

This verticalization concept brings all the Bonfiglioli teams together to focus on the organization’s technological advantage and strong specialization that greatly benefits end users.

This verticalization concept brings all the Bonfiglioli teams together to focus on the organization’s technological advantage and strong specialization that greatly benefits end users.  Founded in 1909, Xtek was known as the Tool Steel Gear & Pinion Company. A young inventor, Russell Bloomfield, was seeking a way to make cup and cone bearings for bicycles that could take the harsh pounding of the period’s cobblestone streets. Bloomfield’s work led to the development of a steel hardening process that eventually became known as the Tool Steel Process (TSP) because the metallurgical properties that it imparted to gears and bearings made them “as hard and as durable as tool steel.”

Founded in 1909, Xtek was known as the Tool Steel Gear & Pinion Company. A young inventor, Russell Bloomfield, was seeking a way to make cup and cone bearings for bicycles that could take the harsh pounding of the period’s cobblestone streets. Bloomfield’s work led to the development of a steel hardening process that eventually became known as the Tool Steel Process (TSP) because the metallurgical properties that it imparted to gears and bearings made them “as hard and as durable as tool steel.”  Nuttall Gear provided the upgraded gear drive based on their long-standing working relationship with the customer and their reputation for designing and manufacturing robust steel mill gear drive solutions.

Nuttall Gear provided the upgraded gear drive based on their long-standing working relationship with the customer and their reputation for designing and manufacturing robust steel mill gear drive solutions. Delroyd engineers met with the hot mill managers to conduct an on-site inspection and short-term mill stand monitoring period. Through these efforts, it was determined that the cause of the drive failures was that three different gearing manufacturers had supplied gearing, all with different thread designs, which were being mixed and matched over time.

Delroyd engineers met with the hot mill managers to conduct an on-site inspection and short-term mill stand monitoring period. Through these efforts, it was determined that the cause of the drive failures was that three different gearing manufacturers had supplied gearing, all with different thread designs, which were being mixed and matched over time. Based on their findings, Delroyd engineering developed new worm gear sets utilizing aluminum bronze gears and redesigned the bearing mountings to enhance strength and durability. A carburize hardened, ground, and polished alloy steel worm develops a smooth, work-hardened surface on the aluminum bronze gear. Extra-heavy side plates were used to connect the worm and gear shaft bearing supports, assuring proper meshing of the gear under all conditions of load. A more rigid fabricated steel housing design was utilized to reduce bending moment stresses. A redesigned, more efficient lubrication system was also incorporated.

Based on their findings, Delroyd engineering developed new worm gear sets utilizing aluminum bronze gears and redesigned the bearing mountings to enhance strength and durability. A carburize hardened, ground, and polished alloy steel worm develops a smooth, work-hardened surface on the aluminum bronze gear. Extra-heavy side plates were used to connect the worm and gear shaft bearing supports, assuring proper meshing of the gear under all conditions of load. A more rigid fabricated steel housing design was utilized to reduce bending moment stresses. A redesigned, more efficient lubrication system was also incorporated.