The Doomsday Clock is Ticking for Gearmotor Manufacturers

The Doomsday Clock is Ticking for Gearmotor Manufacturers

Within a couple years, all gearmotors will have to be premium efficient — will you be ready?

Erik Schmidt, Assistant Editor

For Groschopp Sales Manager Ed Tullar, the clock is ticking.

Tick.

Tick.

Tick.

The secondhand on the Doomsday dial ominously spins around the face, slowly but ever so surely inching the motor industry towards its inevitable terminus:

Jan. 1, 2017.

The day the IE2 motor will die for good.

“IE2 motors are pretty much dead now,” says Kitt Butler, senior program manager for Advanced Energy - Motors & Drives. “IE3 motors were mandated in an EU directive January 1, 2015 and they are equivalent to NEMA Premium which was regulated in 2010 in the US. IE2 are still being used in special applications in Europe and that may be for things like gearmotors. They are to be phased out completely by 2017. But I suspect if you tried to purchase an IE2 motor today on the open market you could not find it.”

With another new law — the DOE Electric Motor Rule, which covers electric motors with non-standard end shields or flanges — going into effect on June 1, 2016, all gearmotors over 1 horsepower will soon fall under the sprawling umbrella of legislation pushing for what has been dubbed “premium effiency”. Scampering is perhaps an imprudent word, but gearmotor manufacturers who have not yet met the IE3 minimum energy performance standards or NEMA Premium are certainly beginning to move with slightly more urgency as Doomsday approaches.

Fractional gearmotors, as fate would have it, are the last unturned stone. And, according to Butler, a law forcing them to upgrade to IE3 or NEMA Premium could be coming “within a couple of years”.

“We have to meet the law,” Tullar says. “There’s a new fractional motor law coming out sometime in the future and we will have to get more efficient. We don’t fall under the law yet — but we know we will soon.”

Tick.

Tick.

Tick.

Father Time is closing in, and the clock is racing.

Will you be ready when it strikes midnight?

Lightening the Load

There is little doubt that efficiency is one of the buzziest words in the motor industry. The world in its totality is attempting a complete purge of all things wasteful, and with that greener way of thinking has come new legislation encouraging manufacturers to reduce energy consumption.

Picture this: Roughly 30 million new electric motors are sold each year for industrial purposes. Some 300 million motors are in use in industry, infrastructure and large buildings. These electric motors are responsible for 40% of global electricity used to drive pumps, fans, compressors and other mechanical traction equipment, according to Leonard Energy.

Those numbers are certainly big, and the burden that falls on the gearmotor industry to be more efficient remains heavy. So what are companies doing to lighten the load?

“Gearing is one of the most important factors,” says Brother Gearmotor Applications Engineer Juan Avalos on how to improve efficiency in a gearmotor. “If you’re looking at a helical gear versus a spur gear — those two just have innate differences in terms of efficiency. If you’re going to use spur, that’s usually more efficient than a helical gear. At the same time, helical has advantages over the spur, such as a smaller size to carry the same amount of load and less noise. So gearing is number one for efficiency.

“That’s the gearbox side of it. Then the other side of it is the electrical motor. We’re going to be doing the IE3 gearmotor now, so basically it’s just a difference in the motor construction. It can handle flux better and the power factor is a lot better. It’s going to allow it to draw less actual wattage.”

Over at Groschopp, a manufacturer of electric fractional horsepower motors and gearmotors for OEM and distribution products, Tullar and design engineer Scott Lundquist have been working on other ways to increase efficiency.

“We do our best to design for efficiency when looking at our standard products or a customer’s specific design,” says Lundquist. “One of the first factors that go into that is having the correct sizing of the gearbox. I don’t want to get too big or have too big of gears for the application. If the teeth are too thick that may bring the efficiency down. It would have a very high safety factor, but the efficiency may decrease a little bit. Getting that right size of gears in there that is ideal for the application is one thing we look at.”

According to Tullar, Groschopp has an extensive testing process it goes through in order to maximize the efficiency of its gearmotors in any given application.

“We have a program where we test all of our motors to run continuously and intermittently, and we check for power as well as thermal capabilities of insulation and everything else. Most motors don’t run continuously. We’re the only ones that I know of that if you give me a duty cycle I can tell you what the thermal of that motor is.

“Here at Groschopp, we have put in thousands and thousands of hours to calculate what will be the most efficient thing for the application.”

Added Lundquist:

“In that case, you’re getting the right size motor for the right duty cycle. If we have a duty cycle that is only half a minute and then is off for 10 minutes, but it allows us to size our package down, then that helps efficiency and doesn’t pull as much current. It’s better for the customer in the end because it doesn’t cost as much and they’re not putting as much power through it either.”

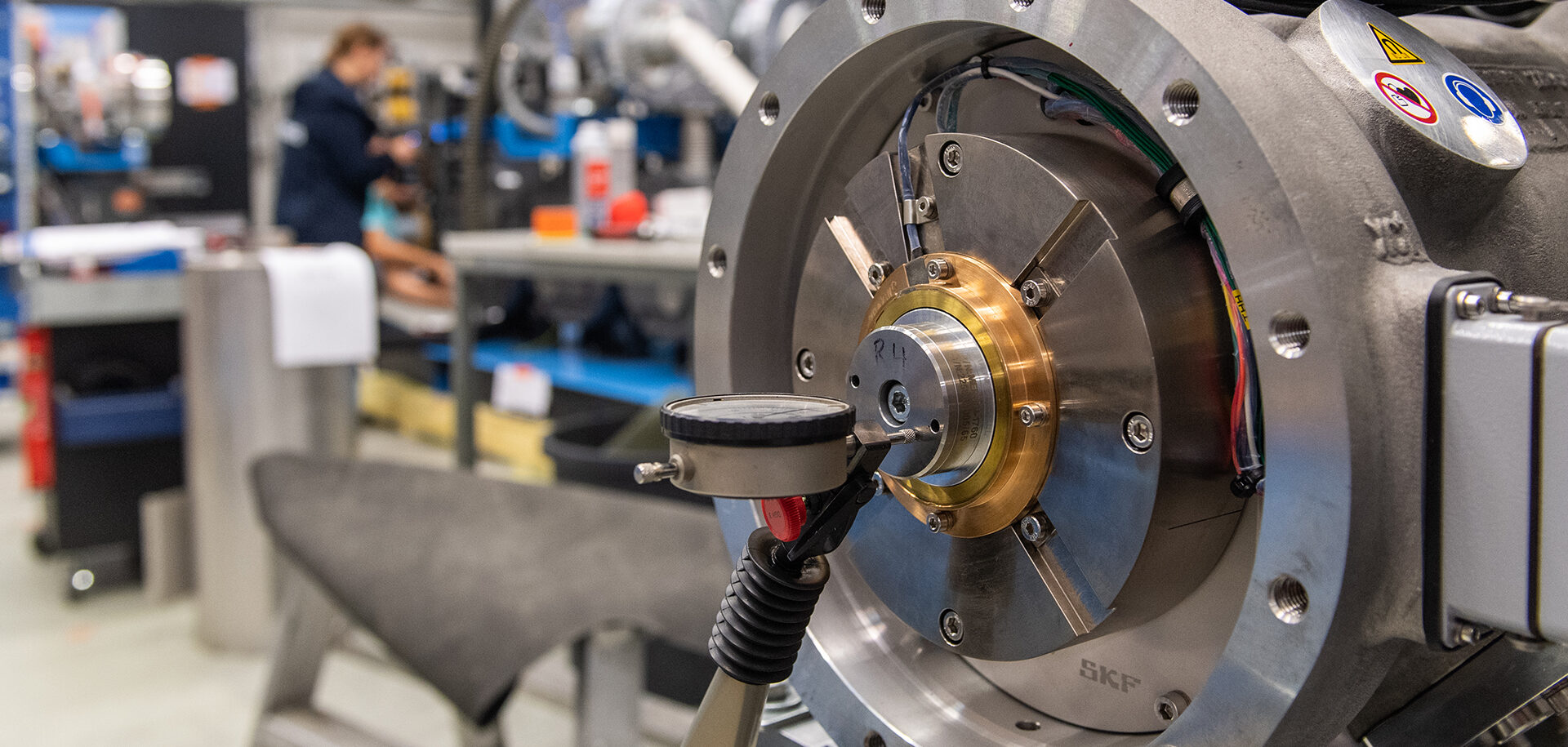

The expanded DOE Electric Motor Rule will go into effect on June 1, 2016. It covers electric motors with nonstandard

end shields or flanges, which equates to gearmotors.

- Click image to enlarge

A peripheral concern is what lubrication is being used, according to Lundquist.

“It’s something we at least consider when we’re designing gearboxes,” he says. “We can look at the type of lubrication that we use, whether it be oil or grease. We may need to use a type of lubrication for another reason — customer requirements or temperature requirements. But we do pay attention to the viscosity of the lubrication that we use and how it affects efficiency.

“We are aware of how much lubrication is put in the gearbox. We did a design where we basically filled it up with lubrication and it was a very high speed gearmotor. The input speed was close to 10,000 RPM and when we ran our test we had too much heat produced by the gearbox. We ended up having too much oil in the gearbox. We were churning the oil in there and that was increasing heat in there and reducing efficiency.

“These are all things that need to be looked at to increase efficiency.”

The Path to Premium Efficiency

For those possessing the complete spectrum of human emotion, tragedy — more so than any other sensation — often sparks change. True enough, we’ve arrived at this crossroads because of multiple incidents of great distress.

Due to the 1979 oil crisis, the Chernobyl disaster in 1986 and a worldwide need for more power, there has been increased attention paid to energy conservation awareness over the last three decades. Here is a brief timeline of the events:

In 1992 the U.S. Congress, as part of the Energy Policy Act (EPAct) set minimum efficiency levels for electric motors. In 1998 the European Committee of Manufacturers of Electrical Machines and Power systems (CEMEP) issued a voluntary agreement of motor manufacturers on efficiency classification, with three efficiency classes, according to the American Council of Energy-Efficient Economy.

According to a paper produced by Siemens entitled “ABC of Motors”, in 1998 CEMEP issued an agreement of motor manufacturers on efficiency classification, with three efficiency classes: Eff 1 for High Efficiency; Eff 2 for Standard Efficiency; and Eff 3 for Low Efficiency.

In June of 2005 the European Union enacted a Directive on establishing a framework for setting Eco-design requirements for all energy using products in the residential, tertiary and industrial sectors, according to the International Electromechanical Commission, according to an article run by ManagEnergy earlier this year. Coherent EU-wide rules for eco-design will ensure that disparities among national regulations do not become obstacles to intra-EU trade, said the article. The directive does not introduce directly binding requirements for specific products, but does define conditions and criteria for setting requirements regarding environmentally relevant product characteristics and allows them to be improved quickly and efficiently. It will be followed by implementing measures which will establish the eco-design requirements. In principle, the Directive applies to all energy using products and covers all energy sources, the article said.

On Dec. 19, 2007, President George W. Bush signed the Energy Independence and Security Act of 2007 (EISA) into law. NEMA participated in crafting major provisions on EISA. One of the most crucial provisions that NEMA focused on was increased motor efficiency levels. The Motor Generator section of NEMA joined forces with the American Council for an Energy Efficient Economy to draft and recommend new motor efficiency regulations covering both general purpose and some categories of definite and special purpose electrical motors, according to NEMA Premium Motors.

On July 22, 2009, Commission Regulation (EC) No 640/2009 implementing Directive 2005/32/EC stated that in the EU, with the exception of some special applications, motors shall not be less efficient than the IE3 efficiency level as of Jan. 1, 2015. The Directive also states all motors (from 0.75 to 375 kW) must be IE3 by Jan. 1, 2017.

And lastly, the Small Motor Rule was passed in 2014. According to an article by Chris Medinger that was published in the December 2014 issue of Power Transmission Engineering, the rule covers two-digit NEMA frame single- and three-phase 1/4 through 3 horsepower motors in open enclosures. The mandate is expected to save appoximately seven quads of energy, reduce $41.4 billion in energy costs and cut 395 million metric tons of carbon dioxide.

At face value, this all appears to be an undeniably favorable sequence of events. Tullar, however, isn’t yet convinced that premium efficiency is all it’s promised to be.

“There’s energy efficient washing machines now,” he says. “Well, it used to take 20 minutes to wash a load of clothes and now it takes me an hour. I don’t know if that’s any more efficient. Dishwashers use to run 40 minutes and now they run three hours. Are we really saving the water or the electricity that we thought we were?”

Still, initial projections are promising.

Based on U.S. Department of Energy data, it is estimated that the NEMA premium-efficiency motor program would save 5.8 terawatts of electricity and prevent the release of nearly 80 million metric tons of carbon into the atmosphere over the next ten years.

That is equivalent to keeping 16 million cars off the road.

For Tullar and Groschopp, it’s not a bridge they have to cross — yet. Fractional gearmotor companies, at this time, still aren’t confined to any laws stating that they absolutely must go to IE3 or NEMA Premium. It will be, as the saying goes, the last hat to drop, and Groschopp will be ready when it does.

“We’re waiting to see when the new laws come out, but have we checked into the new laminations, building materials and tested all of that stuff? — absolutely,” Tullar says. “Do we want to spend the money to buy new laminations right now? — probably not.”

Brother, because it manufactures gearmotors over 1 horsepower and falls under the law beginning in mid-2016, introduced its first IE3 gearmotors at Pack Expo Las Vegas on Sept. 23.

According to Avalos, the new gearmotors offer increased efficiency over standard IE1 models throughout the speed range and initiate less mechanical stress, which directly translates into long-term energy savings. The IE3 gearmotors run cooler and with less noise and, as they are sealed for life and require practically no maintenance, reduce costly downtime. Two of the factors in the enhanced durability of Brother’s IE3 gearmotors are the company’s long-lasting e-coat paint, and increased lubrication through the use of premium H1 food-grade grease.

Though it’s not an entirely apt comparison because they’re operating under slightly different circumstances, Brother and Groschopp have still presented us with two different, legitimate options when it comes to upgrading to premium efficiency: be proactive and get ahead of the curve or be cautious and wait it out. What’s the line in the sand between the two philosophies? Well, it’s cost, of course.

“To increase our cost when we don’t have to yet doesn’t make sense for us,” Tullar says. “We’re in a very competitive market. The thing about the 1 horsepower motors and above is that there are a few people that use them. For the fractional, the prices are less and the buyings are higher.”

Now, most gearmotor manufacturers will fall somewhere between Brother and Groschopp, and yet there is another, far less traveled path to be taken: IE4.

Yes, while most of the world is still making the transition to IE3 and NEMA Premium low-voltage motors, some companies have decided to join Marty McFly in the future ahead of schedule. IE4 motors, dubbed “Super Premium Efficiency” motors, have actually been on the market for some time, and since 2009 have posted consecutive, double-digit growth rates and almost quadrupled in value in 2013 to reach $114.7 million with nearly 259,000 units shipped, according to a Jan. 20, 2015 article published by www. automation.com.

So why have some companies surged ahead to IE4 while others are still spinning their tires at IE2 or below? Once again, cost is the obvious culprit.

“It is possible to go to IE4, but it’s more expensive for the company to manufacture,” Avalos says. “Therefore, if it’s more expensive for the company to make it, it’s more expensive for the customer to buy it. There’s a big economic factor there. Everyone has to have time to do the proper research and development and weigh benefits against their competitors.”

At this point, IE4 is the highest efficiency that has an actual designation. IE5, according to Avalos, is currently just speculative. And after that? Who knows? After all, the clock never stops ticking.

“It’s really dependent on the technology,” Avalos says of continuously increasing gearmotor efficiency. “To get higher efficiency, you’re going to have to do something different. You’re going to have to use a new material, you’re going to have to change the way the rotors are designed, and you’re going to have to make something so there’s less losses.

“Especially at our size of motor, the changes could be very minimal — like maybe 1%. If we start getting up into the bigger horsepower motors, it’s even less of a change because those are already so efficient. If you have a 200 horsepower motor the change could be less than 1%. Of course, if you want to do that it would be a really big investment and the whole company would have to alter all its motor designs. It will happen eventually, just not today.”

Tick.

Tick.

Tick.

You hear that? That’s the sound of change.

And it’s getting closer and closer.