Calculation of the Efficiency of Worm Gear Drives

Calculation of the Efficiency of Worm Gear Drives

This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This computation is based on the Institute of Machine Elements, Gears, and Transmissions (MEGT) tribological simulation, which can determine the local tooth friction coefficients (Ref. 1). With this knowledge other power losses such as the bearings, oil churnings and seals power losses can also be calculated.

Introduction

Worm gears belong to the cross axis drives; with them a very high gear ratio can be realized in one stage. But this advantage is coupled with a high sliding velocity between the meshing gear teeth. Therefore the tooth friction and also the tooth friction power losses are higher than with other gear variants. By the construction of gear solutions it is important to know their future efficiency. Previous calculations can help engineers to compare the different solution principles with each other and to choose the best variant. In this case, a singleworm gearbox competes with a complex multi-stage, helical gear/bevel gear transmission. By the last variant, more responsible empirical equations exist to predict the power losses in all stages (Refs. 2–4). Unfortunately the standardized empirical calculation method (Ref. 5) for determining the efficiency of worm gear drives is not useful if the gear ratio differs from 20.5. Another disadvantage of this calculation is that it ignores the variation of lubricant oil and surface roughness. These omissions complicate the prediction of the efficiency of worm gear drives. At the University of Kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. This method is able to calculate the local tooth friction and thereby the efficiency of the gear meshing. Taking into consideration the other loss components in the gearbox, the efficiency of the complete gear unit can also be calculated. This calculation method is presented in detail in this paper.

Power Flow in Worm Gear Drives

Worm gear units are very compact; a single gearbox includes only two shafts with the coupled worm and worm wheel, bearings, seals, and oil sump. These machine elements cause power losses in the transmission. Therefore the losses in worm gear drives can basically be traced back to four reasons; tooth friction Pltf; oil churning Plchur; bearings Plbear; and shaft seals Plseal losses. The potential loss sources in a worm gearbox and the power flow assigned to the Shafts 1 and 2 in a worm gear drive are illustrated in Figure 1. To determine these power losses it is necessary to know the local loads of every machine element. The loss sources can be divided into load-dependent and no-load-dependent components. Load-dependent power losses are the tooth friction power losses and the bearing power losses. But the latter has also a no-load-dependent part. Other no-loaddependent power losses are the churning and the shaft seals power losses. In the next section the determination of power losses is described.

Calculation of Power Losses in Worm Gear Drives

Tooth friction power losses. To determine the tooth friction in worm gear drives, a tribological calculation method has been developed at the Institute of Machine Elements, Gears, and Transmissions (MEGT), University of Kaiserslautern (Ref. 1).This simplified tribological model of the tooth meshing by worm gears is shown in Figure 2.

The first step of this calculation is determining the contact. Worm gear drives have a line contact. Several points of the current contact line are calculated by a solution of the “equation of meshing.” According to the equation of meshing, the normal vector of the common surface is perpendicular to the relative velocity vector of the bodies at the contact point (Ref. 6). Between two calculated contact points of a single contact line — according to Niemann — the tooth flanks are substituted by rolls whose radius coincides with their reduced radius of the curvature, and the rolls perform rotational motion of the same or opposite direction as the velocity valid for the given contact point. If the pressure mound above the flattening was approached according to Hertz, then the oil film thickness between the pairs of rolls can be calculated analytically (compare Figure 2). Because worm gear drives are usually working under mixed lubrication, it is necessary to determine the local proportions of the dry and fluid friction mechanisms. It is estimated with pre-computed division curve, which represents the rate of boundary lubrication depending on the dimensionless film thickness. The generation of this curve is based upon the statistical description of the representative roughness profiles of the tooth flanks and the contact mechanics (Ref. 1). With knowledge of the film thickness and the rate of boundary lubrication, the load distribution along the contact lines can be calculated iteratively. This technique was developed by Bouché (Ref. 7) and is based on the special wear properties of worm gears with full contact pattern. In the next step of the simulation a mixed friction coefficient between a pair of rolls is recorded. The friction between the teeth generates heat rise. Therefore both the contacting surfaces and the oil film between them are heated by friction. The calculation of the surface temperature is based on the numerical solution of Fourier’s law for heat conduction. Our solution-technique is founded on Plote’s method with Fourier integrals (Ref. 8). The oil temperature in the contact is calculated according to the simplified energy equation of the oil film. To calculate the surface temperatures and the oil middle temperature, the Fourier and the energy equations are solved simultaneously. Knowing the distribution of the oil temperature, an oil viscosity and an oil film shearing can be calculated as well. This shearing is two-dimensional in the gap by worm gear drives. By integrating the shear stress along the penetration surface, the frictional force arising from hydrodynamic lubrication can be elaborated. In mixed lubrication, the friction coefficient consists of a component arising from boundary lubrication and one arising from hydrodynamic lubrication. These components are weight by the abovementioned division curve and so the coefficient of the mixed friction is already known. As this value was freely chosen at the beginning of the thermal calculation, the last computation steps must be repeated in an iteration loop until the error is acceptable. After this calculation the local parameter — for example, oil film thickness, contact pressure, surface temperatures and the coefficient of the tooth friction — are known.

To analyze the efficiency of the worm gear drives the average coefficient of the tooth friction was determined in every meshing position. In this paper a ZK profile worm gear drive with a = 100 mm center distance and i = 20.5 gear ratio was analyzed. Figure 3 shows the calculated local tooth friction coefficients above the meshing field and their average value above the meshing position. In this case the input driving speed was n1=1,500 1/min and the output torque T2 = 500 Nm. Mineral oil lubrication was used with viscosity class ISO VG 150 by sump temperature ϑs = 60°C.

Figure 3 represents that the local coefficient of the tooth friction is changing strong along a single contact line (the same color belongs to the same meshing position of the worm). It assumes its maximum value at the middle of the tooth where the sum velocity is nearly zero and therefore the boundary lubrication dominates. The average coefficient of the tooth friction μtf is also changing strongly depending on the meshing position of the worm φ1. The curve of the gear meshing efficiency ηmesh follows the change in the average coefficient of the tooth friction with the reverse trend. It can be calculated by using Reference 9:

γm is the lead angle of the worm and α0 stands for the pressure angle. In the knowledge of the gear meshing efficiency the input torque T1 of the gear pair can be calculated. In the next step, based on the technical mechanic, the bearing reaction forces can be determined. By worm gear drives by both shafts generally adjusted bearing arrangements were used. The additional pre-stress load of the bearing is computed according to (Ref. 10).

Bearing losses. Knowing the radial and the axial bearing forces and the rotational speed of the shaft the power loss torque by each bearing can be estimated according to the four source friction model of the SKF company (Ref. 10). This determines the total friction moment in a bearing Ml,bear as a sum of the rolling frictional moment Mrr, the sliding frictional moment Msl, the frictional moment of seals Mseal and the frictional moment of drag losses Mdrag:

The details of their calculation are described (Ref. 10); this method was used by all four bearings of the gears to determine the bearing power loss.

Oil churning power losses. At the mechanical engineering department of ECAM, a physically grounded calculation procedure was developed to determine the churning power loss of a pinion, which immerged in an oil sump (Ref. 11). A similar method by worm gear drives is unknown; therefore the mentioned calculation is also used in this paper to estimate the drag torques Ml,chur:

Where ρoil is the oil density, n the rotational speed of the pinion, A the wetted surface area of the pinion, dm the pitch diameter of the pinion and Cm the dimensionless drag torque coefficient, which can be calculated as follows:

Here h means the submerged depth of the pinion, V0 the oil volume, Fr the Froude and Re the Reynolds number. Both equations are given in the convention used with SI units.

Shaft seals power losses. To determine the frictional loss torque of the seals Ml, seal, the following simple equation according to Ref. 12 was used:

Where dshaft is the diameter of the shaft, bcontact is the contact width of the sealing, μ is the coefficient of the friction in the sealing contact and pa is the average contact pressure in the sealing contact. At this point the use of the SI units becomes necessary.

Energy balance of the worm gear unit. In the knowledge of every loss component calculated with the presented methods, the efficiency of the worm gear drives can be determined. This calculation is based on the energy balance of the worm gear unit. It expresses that the sum of the input power, the output power and the power losses is zero (compare Figure 1). Based on this principle of energy conservation, the efficiency of the worm gear unit can be calculated as follows:

Here the power of the worm Pworm is increased with the power losses of the input shaft; this sum corresponds with the input power of the gearbox. The power of the worm wheel Pwheel is reduced with the power losses of the output shaft; this sum is the output power of the gearbox. Both the power of the worm and the power of the wheel were calculated during the tribological simulation of the worm gear drives.

Influence of the power losses on the power losses. The developed tribological simulation of worm gear drives can only determine the tooth friction power losses of the gearbox. The other power losses, such as the bearings, oil churnings and seals power losses reduce also the output power. Therefore a higher input power than used at the beginning of the tribological calculation is needed to cover the necessary output power of the gearbox. It means that an iterative calculation must be used to determine the real operational condition of the worm gear unit. Figure 4 shows the changing of the input and output torque and the changing of the efficiency during this iteration process. It can be seen that in the first calculation step the output torque of the gearbox reduced by losses is smaller than the necessary value T2 = 430 Nm. In the second iteration step the input torque was increased with the loss torque, which was calculated in the first step, whereupon the determined output torque is approximately equal with the necessary value. After four iteration steps the calculated output torque of the gearbox is exactly equal with the expected torque. Nevertheless, the last two iteration steps are unnecessary from a practical point of view. Using the corrected torques in the second iteration step has little influence on the efficiency as well. The efficiency of the gear meshing is slightly decreasing and the efficiency of the gearbox is slightly growing.

Summary of the described calculation procedure. At this point a short overview about the developed simulation method will be given to determine the efficiency of worm gear drives. The calculation process is illustrated in Figure 5. In the first step of the analyses the local tooth friction coefficients of the worm gear drive were calculated according to (section Tooth friction power losses). Afterwards, from the local tooth friction coefficients the average tooth friction coefficient was determined, which belongs to the current meshing position. With this knowledge the gear meshing forces and the bearing reaction forces are calculated based on the static equilibrium equations. With the mentioned method in (sections Bearing losses; Oil churning power losses; and Shaft seals power losses), the additional power losses such as bearings, oil churnings and seals power losses can be also estimated. These power losses modify the input and output torque of the gearboxes; therefore a new tribological calculation is necessary. If the accuracy of the iteration process is acceptable, the calculation procedure can be stopped and the solutions can be put out.

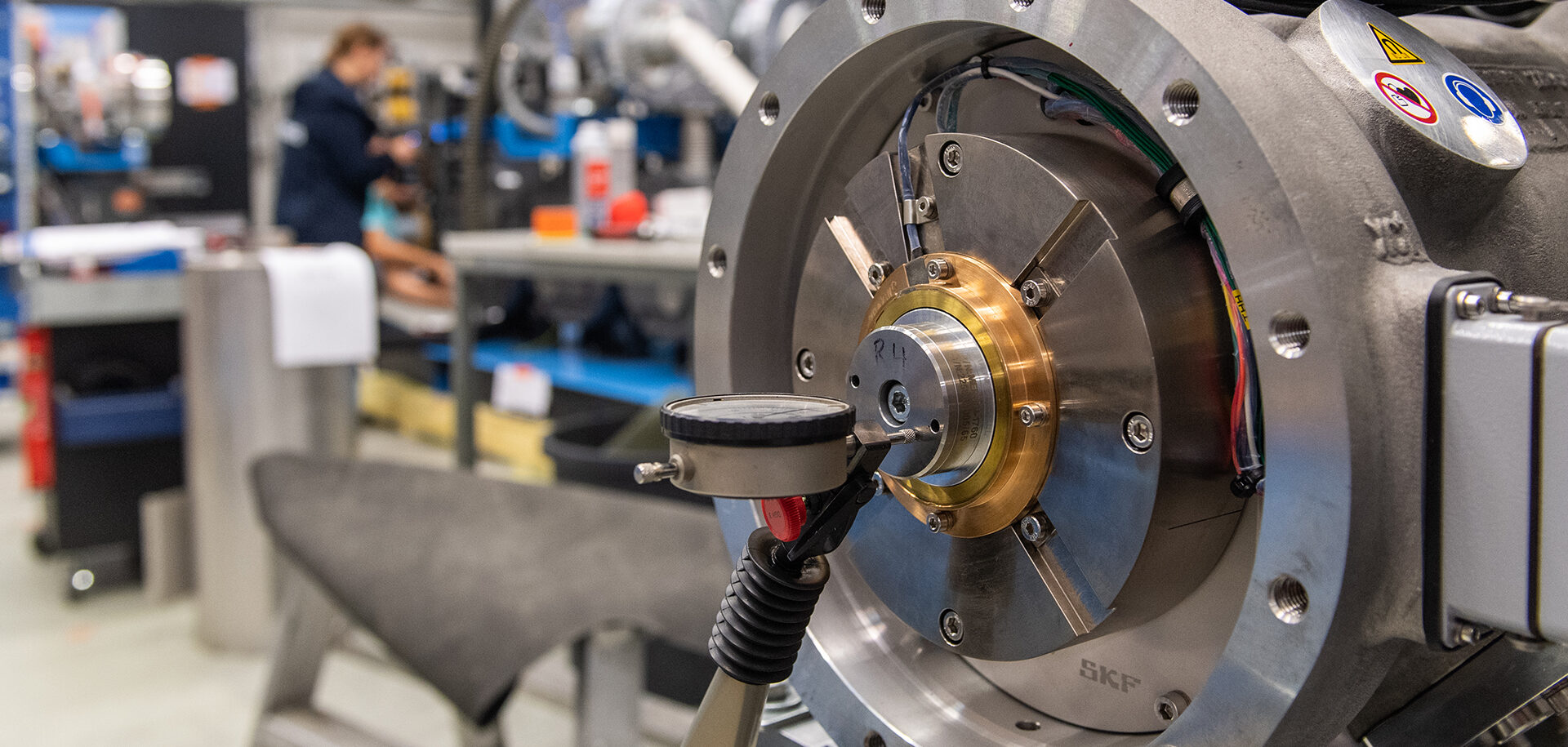

Comparison of the Measurement and the Simulation

To validate the developed calculation method, a test bench was built at the laboratory of MEGT to study the efficiency of worm gear drives. During the experiment the input and output torques and speeds were detected by different operational conditions. Figure 6 shows the comparison of the efficiency calculated from the measured values and the simulated average efficiency of the abovementioned ZK-type gearbox by the load T2 = 430 Nm, and by the sump temperature ϑs = 60° C. The simulated curve of the efficiency concurs very well with the measured values, so the developed simulation technique can be used as a reliable calculation method to determine the efficiency of worm gear drives.

Analysis of Power Losses

The presented, physically grounded calculation method to determine the efficiency of worm gearboxes has a singular advantage compared to conventional empirical equations. While the latter differentiate only between the load-dependent and no-load dependent power losses, the presented calculation method separates also between the power loss sources. This enables engineers to not only estimate total power loss but also to better understand every power loss source. Thus it is possible to optimize the gearboxes and reduction of losses.

Figure 7 shows the course of all four power loss sources during one rotation of the worm by the load T2 = 430 Nm, and by the input rotational speed n1=1,500 1/min. Depending on the meshing position, the tooth friction power loss changes strongly similar to the changing of the tooth friction coefficient in Figure 3. Its average value is ca. three times higher than the second largest power loss — the sum of the four bearings’ power losses. This is also three times higher in the investigated operational point than the oil churning losses. The smallest share has the sum of the three shafts’ seal power losses. For further analysis of the power sources the power losses were divided into two groups, depending upon the location of their generation. Figure 8 shows the power losses by the input (left) and by the output shaft (right). It also shows that the power losses by the output shaft can be ignored compared with losses of the input shaft. The noload- dependent character of the oil churning and the shaft seals power loss should also be easily recognizable (Fig. 8). The high value of the bearing power losses can be explained with the high axial force component of the bearing reaction force and with the high rotational speed of the worm. In the investigated case the worm submerged fully in the sump; therefore the churning loss was accordingly high, whereas the wheel teeth were slightly immersed in the oil sump.

This brief study shows the potential for increasing the efficiency of worm gear drives through reducing the tooth friction power losses and reducing bearing power losses by the worm. The first is possible through the optimization of the gear geometry, reducing the surface roughness, and using adequate lubrication. As for the second, a good bearing concept can be helpful.

Conclusion

The comparison between the measured and the simulated efficiency of the investigated gearbox has shown a very good concordance. It means that the described, complex calculation method can reliably predict the efficiency of worm gear drives. This simulation is also suitable to analyze each loss component of gears, and therefore can help engineers to optimize drive solutions.

References:

- Magyar, B. “Tribo-Dynamische Untersuchungen von Zylinderschneckengetrieben,” PhD Thesis, University of Kaiserslautern, 2012.

- Doleschel, A. “Wirkungsgradberechnung von Zahnradgetrieben in Abhängigkeit vom Schmierstoff,” PhD Thesis, TU München, 2003.

- ISO/TR 14179-2:2001: Gears — Thermal capacity; Part 2: Thermal loadcarrying capacity.

- Klingenberg, J. Kegelräder. Springer-Verlag, Berlin, Heidelberg, 2008.

- DIN 3996:2012-09: “Calculation of Load Capacity of Cylindrical Worm Gear Pairs with Rectangular Crossing Axes,” (in German) Beuth- Verlag, Berling, 2012.

- Litvin, F.L. and A. Fuentes. Gear Geometrie and Applied Theory, Cambridge University Press, Cambridge, 2004.

- Bouché, B. “Reibungszahlen von Schneckengetrieben im Mischreibungsgebiet,” PhD Thesis, Ruhr-Universität Bochum, 1991.

- Plote, H. “Zur Berechnung Thermo-Elasto-Hydrodynamischer Kontakte,” PhD Thesis, TU Clausthal, 1997.

- Steinhilper, W. and B. Sauer. Konstruktionselemente des Maschinenbaues 2, Springer-Verlag, Berlin, Heidelberg, 2008.

- SKF Rolling bearings Catalogue 10000/EN, October 2012.

- Changenet, C. and M. Pasquier. “Power Losses and Heat Exchange in Reduction Gears: Numerical and Experimental Results,” 2nd International Conference on Gears (VDI Berichte 1665) pp. 603-613. VDI-Verlag, Düsseldorf, 2002.

- Tietze, W. and A. Riedl. Taschenbuch Dichtungstechnik, Vulkan-Verlag, Essen 2005.

Balázs Magyar received his PhD in mechanical engineering

in 2012 at the University of Kaiserslautern, and then joined

the University the following year as a junior professor

of tribology. His current research interests include

the tribology of worm gear drives, bearings and shaft

seals. Magyar is now teaching machine elements and

engineering tribology.

Balázs Magyar received his PhD in mechanical engineering

in 2012 at the University of Kaiserslautern, and then joined

the University the following year as a junior professor

of tribology. His current research interests include

the tribology of worm gear drives, bearings and shaft

seals. Magyar is now teaching machine elements and

engineering tribology. Bernd Sauer holds a PhD in mechanical engineering from

Technische Universität Berlin. From 1987–1998, he has

as chief engineer for various companies headed up their

development departments in the high-speed rail industry.

Since 1998, he has served as full professor and head of the

Institute of Machine Elements, Gears, and Transmissions

at the University of Kaiserslautern. His current research

interests include the dynamics and tribology of bearings,

seals and chain drives. Sauer since 2015 has led the Society

of Product and Process Design at the Association of German

Engineers (VDI).

Bernd Sauer holds a PhD in mechanical engineering from

Technische Universität Berlin. From 1987–1998, he has

as chief engineer for various companies headed up their

development departments in the high-speed rail industry.

Since 1998, he has served as full professor and head of the

Institute of Machine Elements, Gears, and Transmissions

at the University of Kaiserslautern. His current research

interests include the dynamics and tribology of bearings,

seals and chain drives. Sauer since 2015 has led the Society

of Product and Process Design at the Association of German

Engineers (VDI).