Drive Lines Gearboxes Bring Flexibility to Machine Tools

Whether cutting, boring, grinding or shearing, modern machine tools have to meet what at first sight appear to be conflicting operational needs. On the one hand they need to provide fast cutting for final finish work and/or the rapid processing of soft materials; but they must also have low speed and high torque capabilities for rough cutting and hard materials.

This dual speed requirement is beyond the capabilities of a spindle motor alone, but can be created by the addition of a two-speed gearbox. With a direct drive or 1:1 gear ratio, the spindle motor runs in high speed mode, while the lower ratio will reduce speed and increase torque. Together the two speed capabilities increase the usability of the machine tool enormously.

The result is that the full cutting power is available across the widest possible speed range. Depending on the motor and gearbox specification it is possible to provide speed ranges with constant power of up to 1:20.

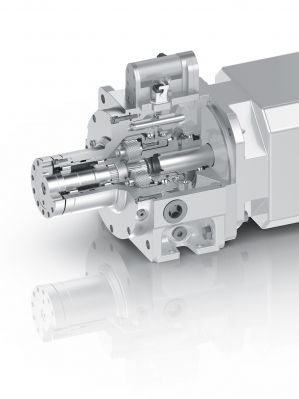

While there are numerous different gearbox designs, planetary gears offer a number of advantages in machine tool applications. For instance they are more compact than most alternatives because the power transmission is shared between several gears, and space saving is always useful in machine design. They are also quiet, reliable and easy to use.

Drive Lines offers the ZF Duoplan gearbox, which is ideal for use in machine tools and many other applications. One of its design features, the floating sun gear, means the Duoplan is tolerant of misalignment and concentricity issues that may arise in machine tool applications. This reduces the generation of heat and vibration during operation, improving reliability and extending the working life of the unit. Further, combining the simultaneously meshing planetary gears with a helical gearing profile assures low noise, even at high operating speeds.

Characterized by their optimized torque transmission capabilities and superior low speed performance, the ZF Duoplan can be used in horizontal or vertical configuration. They can connect straight to the spindle motor without the need for additional components, thus further promoting operational reliability.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.