Avoid over-specifying performance criteria.

Searching for and selecting linear modules based on overly precise performance criteria can lead to linear modules that are more expensive and complex to work with than necessary. For example, some linear modules are available in both steel and aluminum extrusion housings for the guide into the drive system. The steel housing is much more rigid but also has higher costs. Depending on the load to be carried by the module, aluminum housing may be a better solution.

The two most widely used mechanical drives in linear modules are belt drives and ball screw drives. Ball screw drives work best for applications that require a high degree of end-point accuracy and repeatability, as well as carrying or moving loads vertically.

If the packaging machine's linear motion requirements do not require high end-point accuracy, belt-driven linear modules can provide a more cost-effective and fully functional solution. For example, the Bosch Rexroth MKR Belt Driven Module features a high-performance, toothed belt for high drive torques, long travel lengths and high rigidity. This type of linear module is available in multiple lengths and has an end-point accuracy of 500 microns, which can satisfy many applications.

Consider linear module mounting and integration into larger machines.

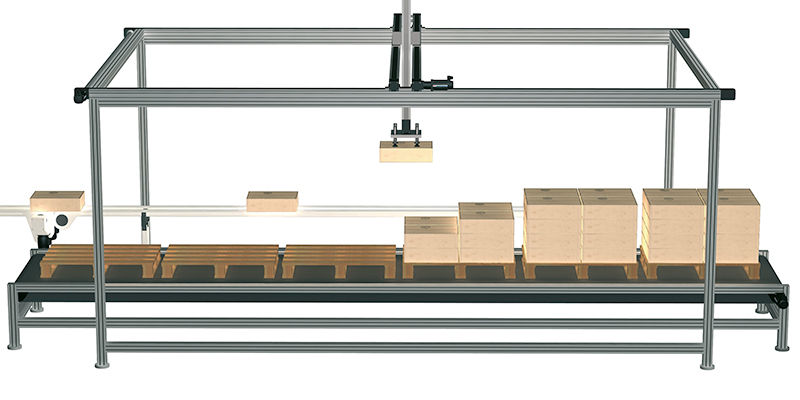

Linear modules are often integrated into larger machines or combined into systems such as pick-and-place Cartesian robots. One item often overlooked is the module connection and mounting. Depending on the supplier, some modules are designed to be mounted only by the base of the extrusion; if the mounting location on the machine doesn't allow for that, additional mounting brackets and other hardware may have to be purchased or machined from scratch, increasing costs and adding time to machine integration.

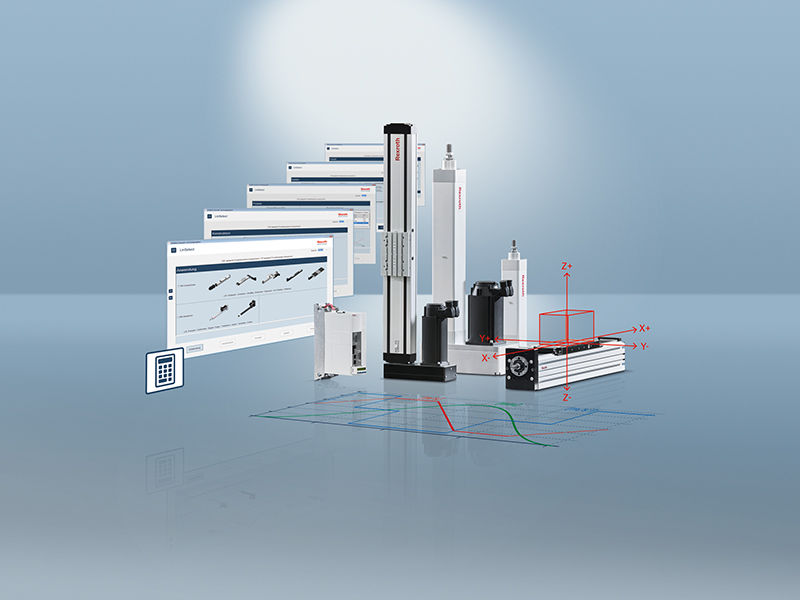

Be sure to investigate how a linear module will be mounted and evaluate mounting options. In addition, check if features are included to help fit and align modules quickly and accurately into tight machine spaces. Standardized, positive-locking connection elements with centering technology alleviate the need for expensive, custom-designed construction. Bosch Rexroth linear module components, for example, feature connecting elements, such as brackets, adapter plates, clamping fixtures, sliding blocks, T-nuts, positive-locking centering rings, etc., designed to simplify installation and integration.

Make sure CAD models are included in the package.

Some linear module suppliers don't include complete CAD models as part of the purchase. While that may lower the initial cost, it's usually necessary to create CAD models anyway in order to properly engineer, configure and integrate the final system. If a CAD model isn't included, the OEM or end-user will need to create their own. However, many companies are scaling back engineering departments to control costs, so this additional task can end up slowing down the project. While many linear module manufacturers include CAD models as standard elements, it pays to be certain.

Use linear modules that have been fully tested to ensure proper mounting and alignment.