Electric Car Safety

Electric Car Safety

Freudenberg Provides DIAvent Pressure Equalization Element for Chinese Passenger Cars

The innovative DIAvent pressure compensation element from Freudenberg Sealing Technologies provides pressure equalization in batteries for electric cars both during normal driving and for emergency venting in the event of damage or accidents. It is therefore an important safety feature for battery-powered vehicles. Freudenberg Sealing Technologies is now starting high-volume production of the component for the first time for use in a Chinese passenger car: DIAvent will help to ensure battery safety in the new ARCFOX α-T electric car from the Chinese manufacturer Beijing Electric Vehicles (BJEV).

(all photos courtesy of FST).

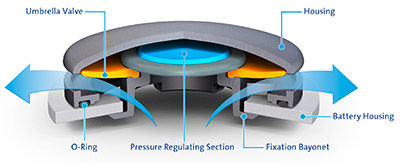

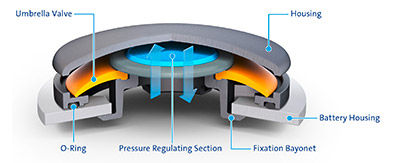

In 2017, Freudenberg Sealing Technologies introduced its innovative pressure compensation element DIAvent to the public: In batteries for electric vehicles, a valve consisting of two nonwovens with different properties takes over pressure equalization during normal operation. Excess pressure reduction during emergency degassing is handled by a reversible umbrella valve. As simple as it sounds, the solution is very technically sophisticated. While only a few liters of air per minute are exchanged in both directions during normal operation, in an emergency the entire quantity of gas emitted from a defective cell must be removed in a few seconds. Otherwise, the strong internal pressure - many times higher than the ambient pressure - could cause the housing to burst.

The trend towards battery systems with even higher energy density is another challenge. This is because it also increases the amount of gas that must be quickly removed in case of an emergency, as well as the amount of air exchanged during normal operations.

Freudenberg’s patented DIAvent valve replaces typically used microporous film like PTFE with a combination of two nonwovens with different properties. The water-repellent nonwoven fabric on the outside allows air exchange of approximately eight liters per minute at a low-pressure difference. And it is watertight up to 100 millimeters of water column. If the water pressure rises above this, a second inner layer of nonwovens is activated so that no water can enter the housing. Degassing in an emergency is made possible by an umbrella valve that is arranged in a ring around the nonwoven fabric. It opens reliably as soon as the pressure in the housing exceeds the atmospheric air pressure by more than 50 millibars and can then discharge 40 liters of gas per second. A major advantage of the DIAvent: the umbrella valve closes again at the end, making it easier to safely remove a damaged battery after emergency degassing. Since it reversibly opens and closes, it can also support pressure equalization in normal operation, for example when batteries with high energy density are exposed to rapid temperature fluctuations.