The first step is to determine whether your disk pack coupling is appropriate for the application, and confirm that it has adequate load capacity. Start by asking the coupling manufacturer to send their service representative to review your application and help you determine whether you have the right coupling for the application. Disk pack couplings come in a variety of types including close-coupled or spacer-couplings, single-flexing or double-flexing, semi-floating or full-floating shaft, and hollow or solid shaft. Once it is confirmed that you have the right coupling type, the next step is to determine whether the coupling size is proper.

Service factor must be large enough

The service factor is a multiplier applied to the normal operating torque to account for the load characteristics of the driving and driven equipment. Besides the normal operating torque, the service factor must be large enough to accommodate harsh duty such as high peak loads or frequent starts and stops. The coupling manufacturer’s catalog rating for the disk pack coupling must be greater than the calculated value of the normal operating torque times the service factor.

Service factors have evolved from experience that is based on past failures (Ref. 1). That is, after a coupling failed, it was determined that by multiplying the normal torque by a factor and then sizing the coupling, the coupling would not fail.

Service factors are used to account for higher torque conditions of the equipment to which the coupling is connected. In API 671, a recommended service (or experience) factor of 1.5 times normal torque is applied for special purpose couplings for refinery service (Ref. 2).

Most manufacturers of disk pack couplings recommend a service factor of 1.5 minimum. However, catalog rating procedures and recommended service factors vary widely, and it is important to follow and use the ratings and service factors recommended by the actual coupling manufacturer and not intermix them with other manufacturer’s rating procedures and service factors.

Startup torque accumulates fatigue damage

Peak torque typically occurs during startup when the driver accelerates the torsional system up to its operating speed. An induction motor is capable of an overload torque of at least three times the normal operating torque. A particularly harsh startup torque occurs with a synchronous electric motor. The startup of synchronous motor driver is usually associated with torsionally excited vibrations and low-cycle fatigue problems. The frequency of these torsional impulses is twice the line frequency at zero speed, and the frequency decreases linearly as speed increases. At synchronous speed the frequency of the impulses becomes zero. As the speed increases during a start, the frequency of the impulses coincides, for a moment, with the lowest natural frequency of the torsional system. During the resonance, the magnitude of the torsional oscillations can develop an overload torque of six times the normal operating torque. Depending on how fast the motor can pass through the critical speed, the coupling will accumulate several cycles of fatigue damage. Unfortunately, disk pack couplings do not provide much damping to limit the dynamic oscillations associated with system resonance. Consequently, frequent starts increase the risk of fatigue failure, and it is prudent to limit the number of starts of a synchronous motor.

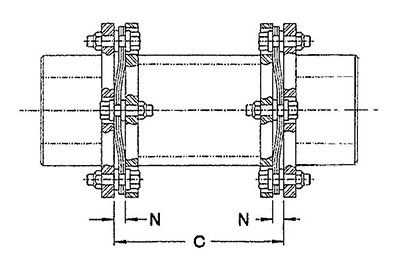

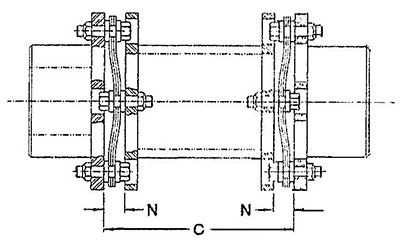

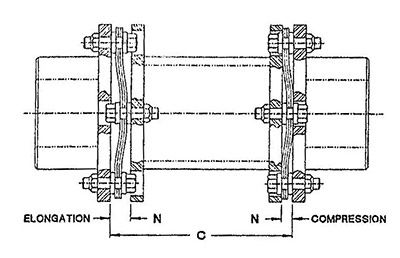

Check the alignment of the coupling

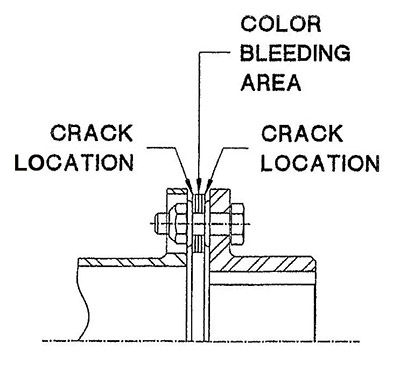

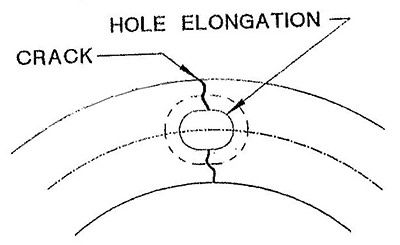

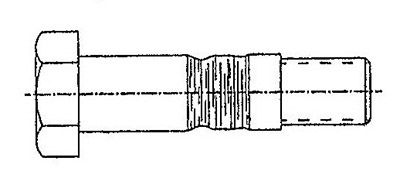

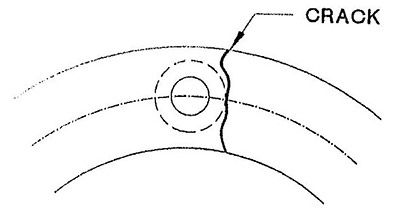

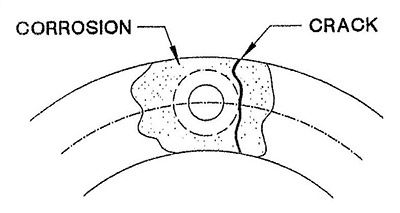

The most common failure of a disk pack coupling is fatigue of the disk pack due to excessive misalignment (Ref. 1). This is usually caused by poor initial alignment of the connected machines. However, it can also be caused by operating conditions. Changes from initial alignment can occur because of bearing wear, settling of foundations, loose anchor bolts, pipe strain, and base distortion due to torque, thermal deformation, and vibrations in connected machines. Alignment checks should be made under cold startup temperature and after the connected machines are at hot operating temperatures. If there is large thermal deformation, it might be necessary to bias the cold alignment to compensate for thermal deformation. The following list describes typical issues with installed disk pack couplings that can lead to failed disk packs (Ref. 2).