An Overview of Fretting Wear

An Overview of Fretting Wear

Introduction

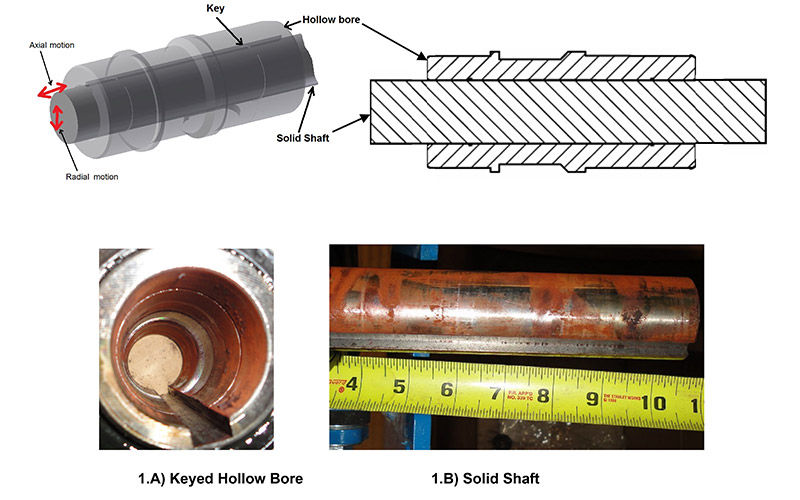

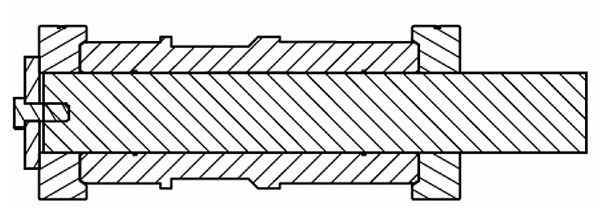

Fretting is considered as a type of wear that occurs in the presence of a small movement between machine components (Refs. 1–2).The small movement could be observed in parts that are not intended to move, and also parts where limited movement is allowed by design. Bolted joints, hollow-bore-shaft mating area, keyways, turbine blade roots, bearing races, shrink fitted and press fitted parts are examples of where unintended movement occurs. And flexible coupling, splines, cams, leaf springs are components that are allowed to have limited internal movement.

Fretting can be elaborated with one of the above examples — hollow-bore and solid-shaft arrangement. Two independent machineries can be connected with this arrangement, in order to transmit power and rotational motion. Fretting is commonly observed at contact surface due to mating parts' unintended relative movements in radial and axial directions. Reasons for those movements could be traced back to the design, manufacturing tolerance and/or installation of the components. The red-color-stained area with some debris (and/or fine red powder) is an evidence of a fretting condition. As a consequence of this condition, the mating surfaces lose their geometric tolerance and create misalignment between components. Often, it becomes impossible to separate the solid shaft from the hollow bore at the time of maintenance, or replacement.

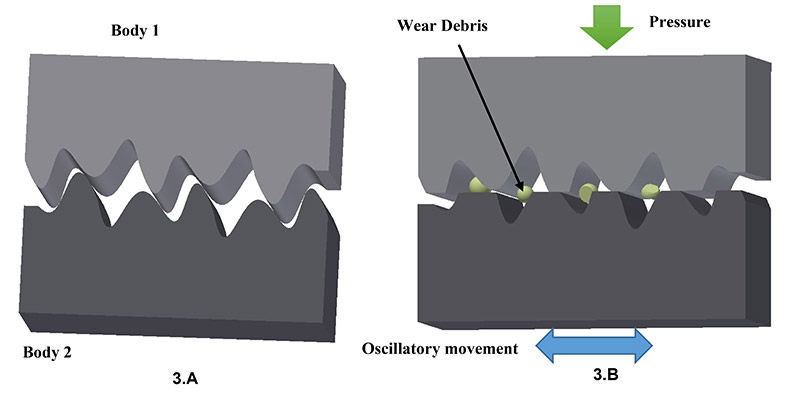

This article dives into the reasons of this failure, its consequences and mitigation methods. The article also discusses about the life prediction of components. First, we will have to understand the fretting failure mechanism.