An Inside Look at Bell's EDAT System

An Inside Look at Bell’s EDAT System

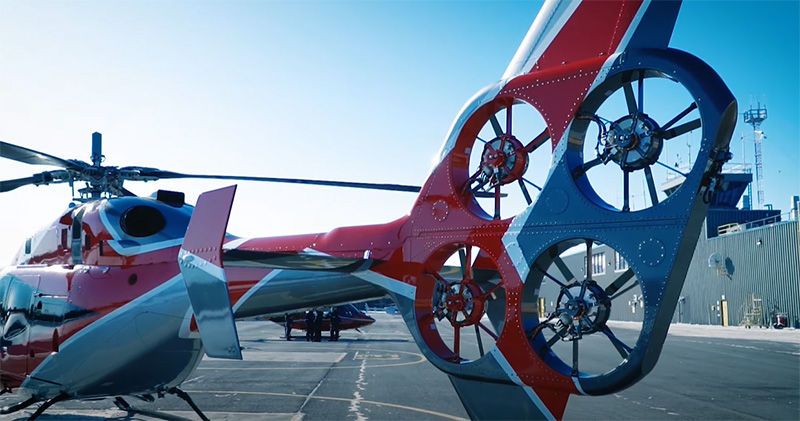

Bell’s Electrically Distributed Anti-Torque (EDAT) is Bell’s latest commercial innovation, unveiled in February 2020. The EDAT system is composed of four small fans within a tail rotor shroud in an offset two-by-two pattern. Each of the rotors contains four blades, and they are powered by four separate motors with the electrical energy provided through generators driven by the turbine engines.

This innovation provides enhancements to reduction in noise pollution compared to an aircraft with a conventional tail rotor as well as lower operational and maintenance costs. Throughout the year, Bell’s EDAT innovation has garnered interest as the first technology of its kind in the rotorcraft industry, challenging the norms for aircraft noise output, safety, and electrical distribution.

“We replaced conventional drive system components—gearboxes, driveshafts, etc.—with electric motors and electric generators that power the motors,” said Eric Sinusas, director, development programs at Bell. “We took an existing helicopter, the Bell Model 429, and we stripped out all the classic drivetrain components that power the tail rotor and we replaced it with the EDAT system.”

This unique electric system offers a variety of rotorcraft benefits including reduced noise pollution, enhanced safety features, and lower operating costs.