A Guide to Gear Automation

Robotic technologies are designed to handle everything from heavy payloads to miniature components

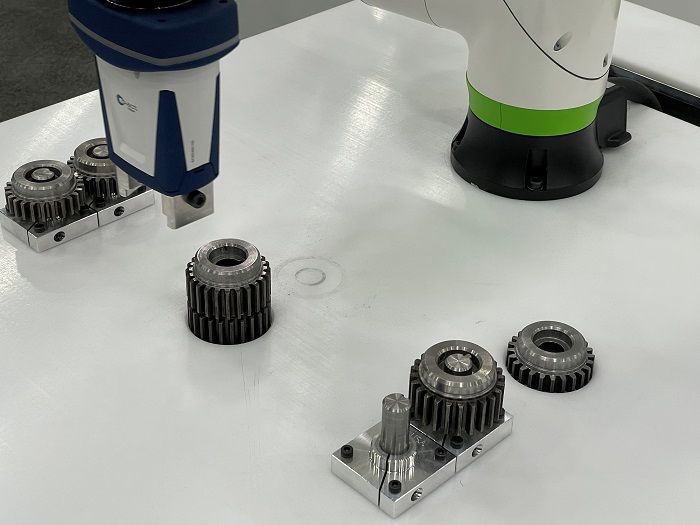

Walk into any gear manufacturing facility and you'll find legacy equipment that has been running successfully for decades. While these machines offer insight from a historical perspective, it's the equipment moving gears through production cells hinting at the factory of the future and the role robotics and automation will play. The skilled labor challenge is not going away, in fact, it's getting more complicated as management navigates ways to keep shipments rolling out in a timely and productive manner - enter the robot in the form of an arm unit, collaborative series or part of an automation cell. Robotic integration on the shop floor will be necessary to keep up with future manufacturing trends and challenges.

AGMA Offers Free Webinar on Robot Simulation

Manufacturers in every industry are adopting robotic automation at an accelerating rate. The investment required for automation is often significant and comes with a host of options. What type or size of robot should be selected? What throughput can be achieved through this new system? Will the workcell fit into my production line?

All of these questions can be answered with Robot Simulation Software. This multi-function tool is invaluable in modeling complicated manufacturing systems. In addition to explaining how Robot Simulation Software can be utilized, this presentation will provide case studies that demonstrate how simulation early in the project can avoid later problems with Robot integration.

“Robot Simulation: Make the Most of Your Investment in Automated Manufacturing” is a free webinar from AGMA’s Emerging Technology Series taking place October 5, 2022, from 1:00 to 2:00 pm (EST). The presenter is Charles Gales, manager of automation sales, Weldon Solutions. Register here: